CNC lathes have become a staple of the manufacturing industry, providing precision and accuracy in the production of complex parts. With the advancements of technology, the capabilities and prospects of CNC lathes are only increasing. New tools, materials, and software are allowing CNC lathes to become even more precise and efficient in their operations. In this article, we will be exploring the upcoming development prospects of CNC lathes, such as the introduction of more advanced machining techniques, improved safety features, and increased flexibility. With these advancements, CNC lathes are sure to remain an important part of the manufacturing process for years to come.

How CNC Lathes are Revolutionizing Manufacturing

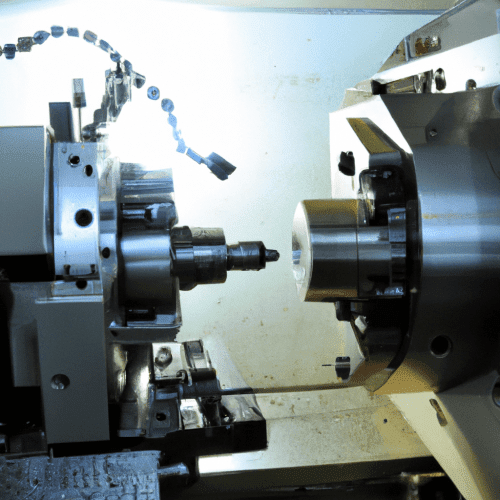

CNC lathes have revolutionized the manufacturing industry by providing greater accuracy, speed, and cost savings. CNC stands for computer numerical control, and it refers to a type of machine that is programmed to produce specific shapes and sizes with precision. CNC lathes can produce parts with greater accuracy than traditional lathes. Traditional lathes require the operator to manually adjust the cutting tool for each operation, which can lead to human error. CNC lathes, on the other hand, are programmed with precise instructions that control the cutting tool.

This ensures that the parts produced are consistent and accurate. CNC lathes also offer greater speed than traditional lathes. Traditional lathes are limited by the speed of the operator’s manual movements. CNC lathes, however, are controlled by a computer, which can perform operations at a much faster rate. This allows for more efficient production and shorter lead times. Finally, CNC lathes can save a manufacturer money. Traditional lathes require a skilled operator, which can be costly. CNC lathes, however, can be run by a single operator or even by a computer, which can lead to significant cost savings.

Overall, CNC lathes have revolutionized the manufacturing industry by providing greater accuracy, speed, and cost savings. They are a valuable tool for any manufacturer looking to increase efficiency and reduce costs.

The Benefits of Investing in CNC Lathes for Small Businesses

Small businesses are increasingly turning to CNC lathes as an efficient and cost-effective way to produce parts for their products. CNC lathes offer a number of benefits that can help small businesses streamline their operations and produce higher quality parts in a shorter time frame, leading to greater profits. One of the key benefits of investing in CNC lathes is improved accuracy. Unlike manual lathes, CNC lathes are computer controlled, meaning that they are capable of producing parts with a much higher degree of accuracy. This improved accuracy reduces waste and improves the quality of the finished product, helping small businesses to be more competitive in the marketplace.

CNC lathes also offer increased efficiency. By reducing the amount of time it takes to produce parts, small businesses can increase their production speed and output. This increased efficiency can help small businesses increase their profits by reducing labor costs and producing more parts faster. In addition to increased efficiency and accuracy, CNC lathes offer increased safety. By eliminating the need for manual operation, CNC lathes reduce the risk of human error and the potential for injury. This increased safety can help small businesses reduce their insurance costs and protect their employees. Finally, CNC lathes offer a greater degree of flexibility.

With the ability to create custom parts with a range of materials, small businesses can produce parts that are tailored to their specific needs. This increased flexibility can help small businesses produce parts that are more cost-effective and of higher quality. Overall, investing in CNC lathes for small businesses offers a number of benefits that can help businesses increase their efficiency, accuracy, safety, and flexibility. By streamlining their operations and producing higher quality parts faster, small businesses can improve their profitability and remain competitive in the marketplace.

Exploring the Latest Developments in CNC Lathe Technology

CNC (Computer Numerical Control) lathes are becoming increasingly popular in the manufacturing industry due to their precision and versatility. This technology is becoming increasingly sophisticated, with new developments improving their speed, accuracy, and effectiveness. In this article, we will explore the latest developments in CNC lathe technology and discuss their potential implications. One of the most significant advances in CNC lathe technology is the use of servomotors. These motors have replaced the traditional stepper motors found in earlier CNC lathes, providing a much higher level of control and precision. Servomotors allow CNC lathes to operate at higher speeds and with more accuracy than ever before. Additionally, servomotors require less energy than stepper motors, resulting in lower operating costs. Another important development is the use of additive manufacturing techniques.

Additive manufacturing is a process that involves creating objects from successive layers of material, as opposed to subtractive manufacturing, which involves the removal of material to create a desired shape. Additive manufacturing allows for the production of complex objects with intricate details. It is becoming increasingly common in the CNC lathe industry, resulting in higher quality parts with improved precision. In addition, advances in software are making CNC lathes more efficient and user-friendly. Software can now be used to automate processes, allowing for faster operation and increased productivity. Additionally, 3D visualization tools allow for greater accuracy in programming, while user-friendly interfaces make it easier for operators to use the machines. Finally, CNC lathes are now being equipped with advanced safety features. These include sensors that detect any obstructions in the work area and automatically shut off the machine to prevent damage or injury. Additionally, they can be equipped with emergency stop buttons that can be used to quickly shut down the machine in the event of an emergency.

In conclusion, CNC lathe technology is advancing rapidly, providing manufacturers with more precise, versatile, and efficient machines. The use of servomotors, additive manufacturing, improved software, and enhanced safety features are all contributing to this progress. As these developments continue, CNC lathes will become even more effective and beneficial to businesses in the manufacturing industry.

The Impact of CNC Lathes on the Manufacturing Industry

The introduction of Computer Numerical Control (CNC) lathes has had a tremendous impact on the manufacturing industry. CNC lathes have revolutionized the manufacturing process, leading to increased efficiency, accuracy, and productivity. This article will explore the impact of CNC lathes on the manufacturing industry, including their advantages, disadvantages, and the future of CNC lathes. One of the main advantages of CNC lathes is that they are highly accurate. CNC lathes use computer-controlled software to program the exact movements of the lathe. This enables the machine to produce precise cuts with a high degree of accuracy. This accuracy is further improved with the help of feedback from sensors and other measuring devices. The accuracy of CNC lathes is beneficial for producing complex parts that require a high level of precision.

CNC lathes are also incredibly efficient. They can produce parts with a much higher rate of speed than traditional lathes, as they require fewer manual adjustments. This reduces the amount of time and effort required to produce a part, resulting in increased productivity. Additionally, CNC lathes are capable of producing a wide variety of parts with minimal setup time. This can drastically reduce the amount of time and money spent on production. Despite their advantages, CNC lathes can be expensive to purchase and require a significant amount of technical knowledge to operate. In addition, CNC lathes require regular maintenance and can be prone to breakdowns. These factors can make CNC lathes expensive to maintain and difficult to use. Looking to the future, CNC lathes will continue to evolve and become more advanced. As technology progresses, CNC lathes will become more efficient, accurate, and cost-effective.

Additionally, more sophisticated software and improved sensors will enable CNC lathes to produce even more complex parts with greater accuracy and speed. In conclusion, CNC lathes have had a profound impact on the manufacturing industry. Their accuracy, efficiency, and productivity have enabled manufacturers to produce high-quality parts with increased speed and reduced costs. Although CNC lathes have their drawbacks, they are likely to become even more advanced and efficient in the future.

The Potential of CNC Lathes for Automation in the Factory

The advent of computer numerical control (CNC) lathes has revolutionized the automation of factory processes. CNC lathes offer a range of advantages that greatly increase the productivity of any factory. They are capable of automatically producing complex parts with high levels of precision and repeatability, allowing for more efficient production processes. Furthermore, CNC lathes are incredibly versatile—they can be used for a wide range of tasks, including turning, drilling, knurling, facing, and threading. CNC lathes are capable of producing accurate, complex parts with minimal human intervention. This allows for higher levels of automation and fewer errors. The flexibility of CNC lathes allows for easier setup and changeovers, allowing for efficient production of different parts.

Furthermore, CNC lathes can be programmed to make adjustments or to adapt to changes in the dimensions of the part being produced. This eliminates the need for manual adjustments, saving time and labor costs. CNC lathes are also capable of producing parts faster and more accurately than traditional lathes. They can run at higher speeds and feed rates, producing parts faster and with greater accuracy. Additionally, CNC lathes are equipped with advanced safety features that reduce the risk of injury while operating the machine. CNC lathes offer a range of advantages that make them essential for any factory that wants to automate its processes.

They are capable of producing complex parts with high levels of accuracy and repeatability, allowing for efficient production of different parts. Furthermore, they are fast and safe to operate, and offer advanced safety features. With these advantages, it is clear that CNC lathes are an invaluable tool for any factory that wishes to increase its automation capabilities.

The Future of CNC Lathes: What’s Next?

The CNC lathe is an invaluable tool for manufacturers and machinists across multiple industries. It is an extremely precise machine that offers a level of accuracy and repeatability that other traditional machines simply cannot match. As technology continues to evolve, CNC lathes will see a number of advances in the near future that will further improve their performance and capabilities. One of the biggest changes in the CNC lathe industry will be the introduction of 5-axis lathes. This will allow machinists to create more complex parts in a shorter amount of time. The 5-axis lathe will also offer a level of precision that is not possible with traditional machines.

This will be especially beneficial for those that require higher tolerances and accuracy. Another significant advancement will be the introduction of additive manufacturing capabilities. Additive manufacturing is the process of creating parts from raw materials using 3D printers. This technology has been around for a few years now, but it is just now being applied to CNC lathes. This will allow for more complex parts to be created with greater accuracy and speed. Finally, the use of robotics and automation in the manufacturing process will become more commonplace. Robotics will allow for more efficient operations and will reduce the need for manual labor.

This will free up time for machinists to focus on more intricate and complex tasks. The future of CNC lathes looks to be very bright. With the introduction of new technologies and advancements, CNC lathes will become increasingly precise and versatile. This will allow manufacturers and machinists to create more complex parts with a higher level of accuracy and speed than ever before.

How CNC Lathes Are Enhancing Productivity and Quality Control

CNC lathes are computer-controlled machines that are used to shape materials such as metal, wood, and plastic. These machines are used in a variety of industries, from automotive and aerospace production to medical device and furniture manufacturing. CNC lathes offer a range of advantages over manual lathes, including increased productivity, greater accuracy and improved quality control. In terms of productivity, CNC lathes are able to produce parts faster than manual lathes. This is due to the fact that CNC lathes can be programmed for multiple tool changes and operations, allowing for more consistent and efficient production.

They can also be programmed to run 24/7, making them ideal for high-volume production. Furthermore, CNC lathes can be run by a single operator, eliminating the need for multiple workers. The accuracy of CNC lathes is also superior to manual lathes. CNC lathes are equipped with digital servo motors, which allow for precise control over the speed and direction of movement. This allows for more accurate cuts and improved repeatability. Furthermore, CNC lathes are able to hold tight tolerances over long production runs, resulting in higher product quality. Finally, CNC lathes provide improved quality control. CNC lathes are programmed with safety features that protect the machine and operator from accidents. Furthermore, CNC lathes can be programmed to monitor the quality of each part and alert the operator if there is an issue.

This helps ensure that parts are produced to the highest quality standards. In conclusion, CNC lathes offer a range of advantages over manual lathes, including increased productivity, greater accuracy and improved quality control. These advantages make CNC lathes an invaluable tool for a wide variety of industries.

The future of CNC lathes looks bright, as they are becoming increasingly important in the manufacturing industry. With advancements in technology, CNC lathes will become more accurate, efficient, and cost effective. Additionally, as the demand for higher quality and precision increases, CNC lathes are likely to become even more commonplace. As a result, CNC lathes are likely to remain a vital part of the manufacturing process for many years to come.