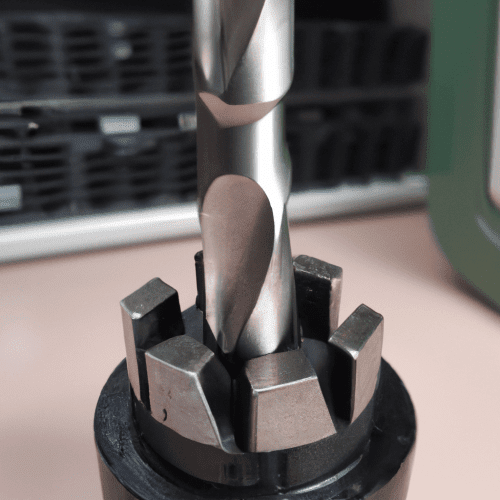

Drill bits are designed to create holes in a variety of materials, and the angles of the drill bit play an important role in the effectiveness of the drilling process. The two main angles that are important to consider when drilling are the point angle and the lip angle.

The point angle is the angle of the tip of the drill bit. This angle determines the sharpness of the drill bit and how easily it will penetrate the material. A sharper point angle will penetrate the material more easily, but it will also wear out more quickly. A duller point angle will penetrate the material more slowly, but it will last longer.

The lip angle is the angle of the cutting edges of the drill bit. This angle determines how much material is removed with each rotation of the drill bit. A steeper lip angle will remove more material with each rotation, but it will also create more friction and heat. A shallower lip angle will remove less material with each rotation, but it will create less friction and heat.

The combination of the point angle and the lip angle will determine how effectively the drill bit will chip away at the material. A sharper point angle and a steeper lip angle will create a drill bit that is more effective at chipping away material, but it will also wear out more quickly. A duller point angle and a shallower lip angle will create a drill bit that is less effective at chipping away material, but it will last longer.

What are the angles on a drill bit?

A drill bit is a cutting tool used to create holes in a variety of materials. It is composed of a cylindrical shaft with a cutting tip at one end and a shank at the other. The cutting tip is typically composed of two or more angles, which are designed to create a cutting edge that is able to penetrate the material being drilled. The most common angles on a drill bit are 118° and 135°. The 118° angle is the most common and is used for general purpose drilling. It is also known as a “split point” because it has two cutting edges that meet at a point. The 135° angle is known as a “parabolic” angle and is used for drilling harder materials such as stainless steel and cast iron. It has a single cutting edge that is curved, which helps to reduce the amount of pressure needed to penetrate the material. Other angles, such as 90° and 60°, are also available and are used for specific applications.

What are the different cutting angles of the twist drills?

Twist drills are a type of cutting tool used to create cylindrical holes in a variety of materials. The cutting angle of a twist drill is the angle between the cutting edge of the drill and the axis of the drill. The cutting angle of a twist drill is typically 118°, but there are several other cutting angles available.

The most common cutting angles for twist drills are 118°, 135°, and 140°. The 118° angle is the most common and is used for general purpose drilling. The 135° angle is used for drilling harder materials such as stainless steel and cast iron. The 140° angle is used for drilling softer materials such as aluminum and brass.

In addition to the standard cutting angles, there are also special cutting angles available. These include the 82° angle, which is used for drilling very hard materials such as titanium and tungsten, and the 90° angle, which is used for drilling very soft materials such as wood and plastic.

What is the name of the angle in the drill bit marked as?

The angle of the drill bit marked as is known as the flute angle. The flute angle is the angle of the cutting edge of the drill bit, which is typically between 118 and 135 degrees. The flute angle is important because it determines the cutting speed and efficiency of the drill bit. A larger flute angle will result in a faster cutting speed, while a smaller flute angle will result in a slower cutting speed. The flute angle also affects the amount of material that can be removed from the workpiece, as a larger flute angle will result in more material being removed.

What is known as the Combined angle of the cutting edges of a drill bit?

The Combined Angle of the cutting edges of a drill bit is the angle formed by the two cutting edges of the drill bit. This angle is important because it determines the cutting performance of the drill bit. The Combined Angle is the sum of the two angles of the cutting edges, and is usually expressed in degrees. The Combined Angle is typically between 118 and 135 degrees, with 118 degrees being the most common. The Combined Angle is important because it affects the cutting performance of the drill bit. A larger Combined Angle will result in a faster cutting speed, but will also cause more wear on the drill bit. A smaller Combined Angle will result in a slower cutting speed, but will also cause less wear on the drill bit. The Combined Angle also affects the chip formation of the material being drilled. A larger Combined Angle will result in larger chips, while a smaller Combined Angle will result in smaller chips. The Combined Angle is an important factor to consider when selecting a drill bit for a particular application.

What is better 118 degree or 135 degree drill bits?

When it comes to choosing between 118 degree and 135 degree drill bits, it is important to consider the type of material you are drilling into and the desired finish. 118 degree drill bits are typically used for drilling into softer materials such as wood, plastic, and aluminum. They have a sharper point and a shorter cutting edge, which allows them to penetrate the material more quickly and easily. 118 degree drill bits also produce a cleaner, more precise hole than 135 degree drill bits.

On the other hand, 135 degree drill bits are better suited for drilling into harder materials such as steel and stainless steel. They have a longer cutting edge and a more blunt point, which allows them to cut through the material more slowly and with less chance of the bit slipping or wandering off course. 135 degree drill bits also produce a rougher finish than 118 degree drill bits.

Which is better 118 or 135 degree drill bits?

When it comes to choosing between 118 and 135 degree drill bits, it really depends on the job at hand. 118 degree drill bits are typically used for general purpose drilling, such as drilling into wood, plastic, and soft metals. They are also great for drilling into thin materials, as they have a sharper point and can penetrate the material more easily. On the other hand, 135 degree drill bits are designed for drilling into harder materials, such as stainless steel and cast iron. They have a more blunt point, which helps them to penetrate the material more easily and reduce the risk of the bit slipping or breaking.

In general, 118 degree drill bits are better for drilling into softer materials, while 135 degree drill bits are better for drilling into harder materials. However, it is important to note that the type of drill bit you choose will also depend on the type of drill you are using. For example, if you are using a cordless drill, you may want to opt for a 135 degree drill bit, as it will be more powerful and able to penetrate the material more easily.

What are the 5 types of drill bits?

Drill bits are essential tools used to create holes in a variety of materials. There are five main types of drill bits, each designed for a specific purpose.

The first type of drill bit is the twist drill bit. This is the most common type of drill bit and is used for drilling into wood, metal, plastic, and other materials. It has a cylindrical shape with two cutting edges and a point at the tip. The cutting edges are angled slightly inwards, which helps the bit to cut into the material.

The second type of drill bit is the spade bit. This bit is used for drilling large holes in wood and other soft materials. It has a flat, paddle-shaped tip with two cutting edges and a point at the end. The cutting edges are angled slightly outwards, which helps the bit to cut into the material.

What is the margin of a drill bit?

A drill bit’s margin is the part of the bit that is not cutting. It is the flat part of the bit that is located between the cutting edges. The margin is important because it helps to guide the bit and keep it centered in the hole. It also helps to reduce the amount of friction between the bit and the material being drilled. The margin also helps to reduce the amount of heat generated by the bit, which can cause the bit to wear out more quickly. The size of the margin depends on the type of bit being used and the material being drilled. Generally, the larger the margin, the more accurate the hole will be.

What is the angle of HSS twist drill?

The angle of a High Speed Steel (HSS) twist drill is the angle of the flutes on the drill bit. The angle of the flutes is typically 118 degrees, which is the most common angle used for general purpose drilling. This angle is also known as the “point angle”. The point angle is the angle between the two cutting edges of the drill bit. The 118 degree angle is the most common because it is the most efficient for cutting through a variety of materials. The angle of the flutes also affects the speed and accuracy of the drilling process. A larger angle will allow for faster drilling, but may not be as accurate. A smaller angle will allow for more accurate drilling, but may be slower. The angle of the flutes also affects the type of material that can be drilled. A larger angle is better for softer materials, while a smaller angle is better for harder materials.