CNC machines, or Computer Numerical Control machines, offer a range of advanced features that revolutionize manufacturing processes. These machines excel in precision, automation, and versatility, allowing for complex part production with minimal human intervention. Key features include multi-axis capabilities, enabling intricate 3D cuts and shapes; tool changers for seamless switching between operations; and advanced control systems that interpret CAD/CAM designs into precise machine movements.

CNC machines also boast high-speed machining capabilities, reducing production time while maintaining accuracy. Many modern CNC systems incorporate adaptive control, automatically adjusting cutting parameters based on real-time feedback. Additionally, these machines often feature integrated quality control measures, such as in-process measurement and error compensation systems, ensuring consistent part quality. The ability to store and recall multiple programs allows for quick setup and changeover between different production runs, enhancing overall manufacturing flexibility and efficiency.

- Important features of CNC machines improve precision and efficiency in manufacturing.

- CNC machines are computer-controlled devices used in the manufacturing industry.

- These machines come with various features that enhance productivity.

- The features of CNC machines contribute to accurate and repeatable production processes.

- CNC machining is critical in industries such as medical, electronics, aerospace, and automotive.

What is a CNC Machine?

A CNC machine, short for computer numerical control machine, is a computer-controlled device used in manufacturing to create or modify parts with precision. It revolutionizes traditional machining processes by automating them through advanced technology.

CNC machines rely on digital instructions from CAD (computer-aided design) and CAM (computer-aided manufacturing) software to carry out the machining process. These programs provide the necessary instructions for the machine to operate and create the desired part.

The beauty of CNC machines lies in their ability to execute complex tasks with high levels of precision and efficiency. By utilizing computer numerical control, these machines eliminate human error and deliver consistent and accurate results.

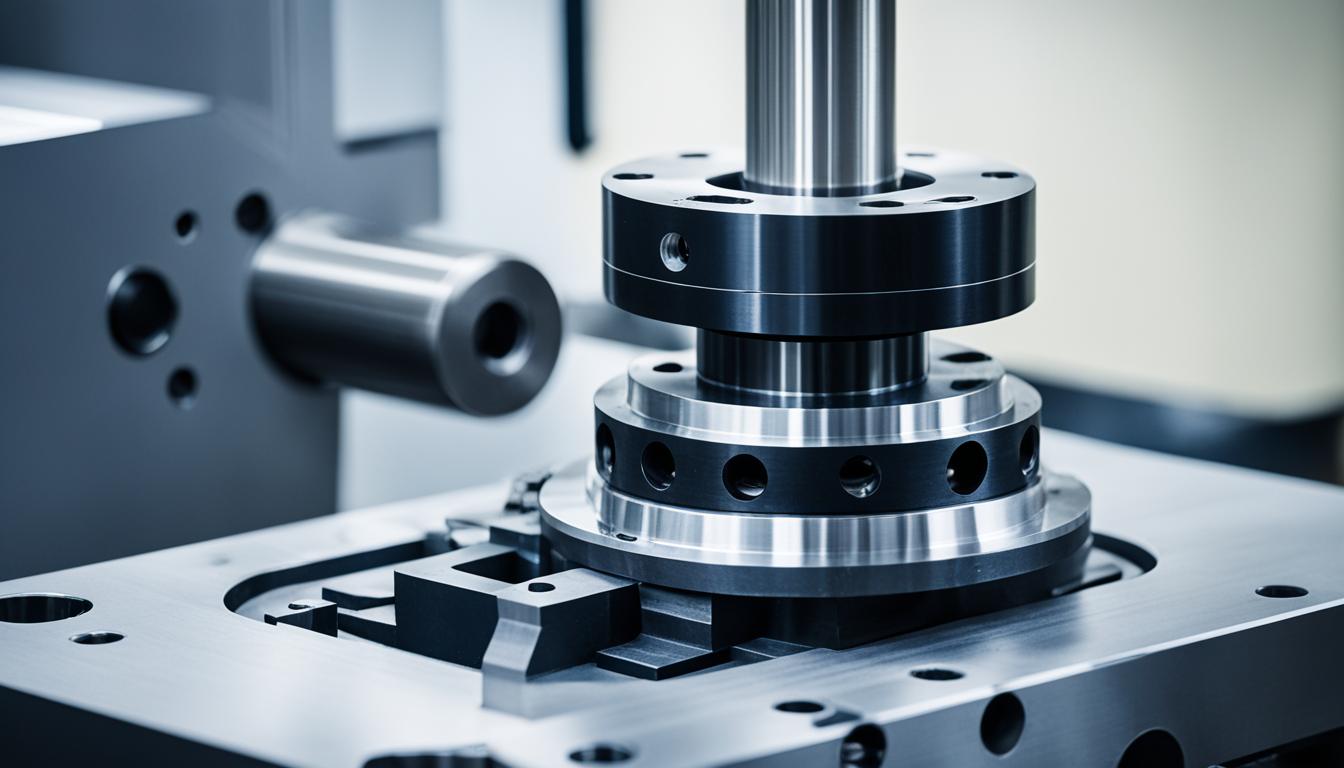

The fundamental components of a CNC machine include:

- The Drive/Motion System: This component moves the tool along the designated path, controlling its speed, direction, and position.

- The Feedback System: It provides real-time information to monitor the position and movement of the tool.

- The Command Function: This component interprets the digital instructions received from the computer and translates them into physical movements of the machine.

By integrating these components, CNC machines can perform a wide range of machining operations, such as cutting, drilling, milling, and grinding, with exceptional precision and speed.

In summary, a CNC machine harnesses the power of computer numerical control to automate manufacturing processes, resulting in faster production times, enhanced accuracy, and improved productivity.

Basic Elements of CNC Machine System

A CNC machine system consists of several essential components that work together to ensure the smooth operation and accurate production of parts. Understanding these basic elements is crucial for comprehending the functionality of a CNC machine.

- Information input/output devices: These devices, such as keyboards and monitors, enable operators to input commands and monitor the machine’s performance.

- Internet connection: Some CNC machines may require an internet connection for remote programming and software updates.

- External mechanical shaft control unit: This unit controls the movement of the machine’s mechanical shafts, ensuring precise positioning and accurate machining.

- Feed servo drive and motor unit: This unit controls the movement and speed of the machine’s cutting tools, allowing for precise material removal.

- Spindle motor and drive unit: The spindle motor and drive unit control the rotation of the tooling, enabling efficient cutting and shaping of the workpiece.

- CNC control unit: The CNC control unit is the brain of the machine, processing the programming instructions and sending signals to the different components for coordinated operation.

- PMC controller: The PMC (Programmable Machine Control) controller manages auxiliary functions and peripheral devices, such as coolant systems and tool changers.

- Feedback and position measurement unit: This unit provides feedback on the machine’s position, speed, and accuracy, ensuring precise control and consistent results.

- Input and output unit of the control signal: This unit handles the communication between the CNC machine and external devices, such as sensors and actuators.

These components work in harmony to create a fully functional CNC machine system. Each element plays a vital role in achieving the desired machining results, offering precision, efficiency, and productivity.

Key Components of a CNC Machine System

| Component | Description |

|---|---|

| Information input/output devices | Devices for inputting commands and monitoring machine performance |

| Internet connection | Enables remote programming and software updates |

| External mechanical shaft control unit | Controls movement of the machine’s mechanical shafts |

| Feed servo drive and motor unit | Controls movement and speed of cutting tools |

| Spindle motor and drive unit | Controls rotation of the machine’s tooling |

| CNC control unit | Processes programming instructions and coordinates machine operation |

| PMC controller | Manages auxiliary functions and peripheral devices |

| Feedback and position measurement unit | Provides feedback on machine position, speed, and accuracy |

| Input and output unit of the control signal | Handles communication between CNC machine and external devices |

Different Types of CNC Machines

There are various types of CNC machines available, each designed for specific machining processes. Let’s explore the different types:

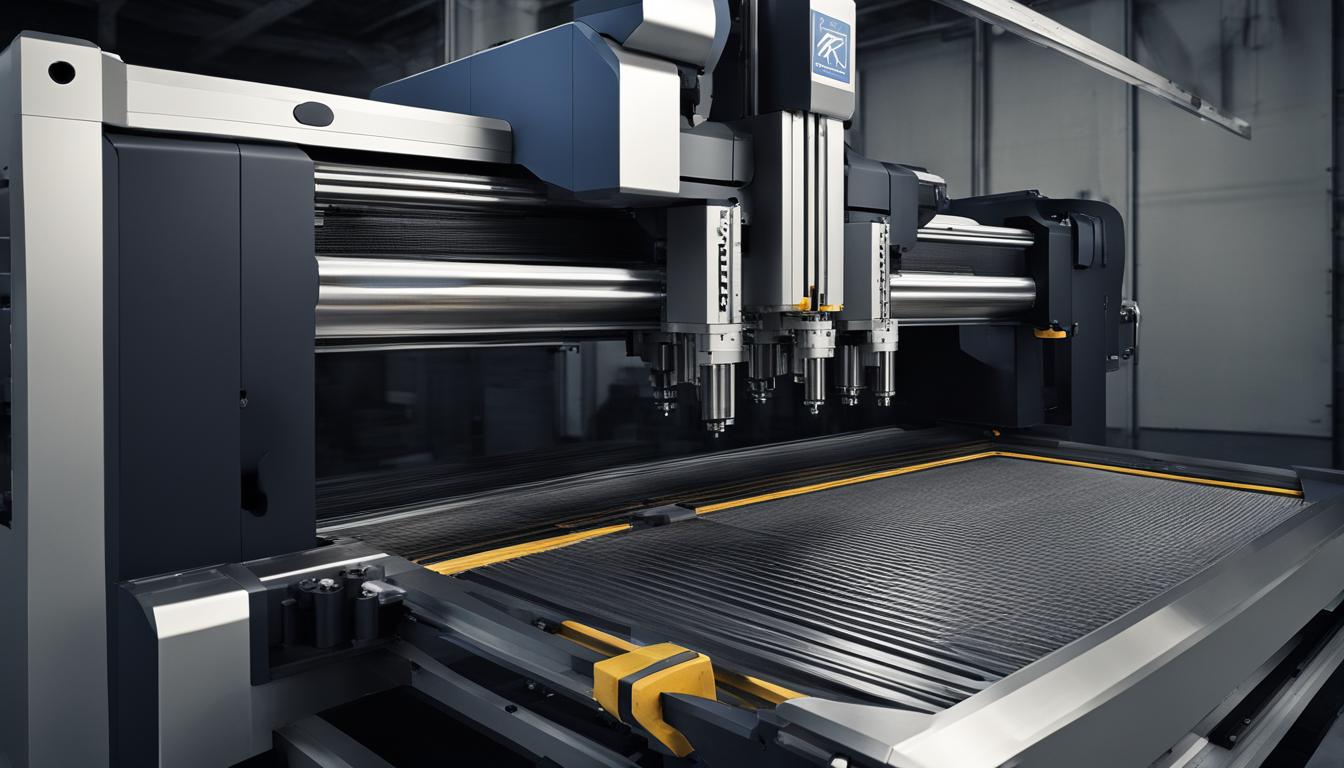

CNC Milling Machines

CNC milling machines are widely used in manufacturing industries. They use high-speed cutting tools to remove material from the workpiece, resulting in precise and accurate cuts. These machines are perfect for creating complex shapes and parts with tight tolerances.

CNC Lathe Machines

CNC lathe machines are used for rotational machining operations. They rotate the workpiece about a primary axis while cutting or shaping it with various tools. CNC lathe machines are ideal for producing cylindrical parts and components like shafts, rods, and bushings.

Drilling CNC Machines

Drilling CNC machines are specialized for drilling holes in different materials. They use precise drill bits and controlled movements to create accurate holes with consistent dimensions. These machines are commonly used in industries such as aerospace, automotive, and construction.

Grinding CNC Machines

Grinding CNC machines are designed for precision grinding and polishing tasks. They utilize abrasive wheels or discs to remove material from the workpiece, resulting in a smooth and polished surface. These machines are commonly used in industries that require high-quality finishes, such as optics, jewelry, and tool-making.

Each type of CNC machine offers unique capabilities and applications in the manufacturing industry, enabling efficient and precise machining processes.

| Type of CNC Machine | Main Function | Common Applications |

|---|---|---|

| CNC Milling Machines | Material removal using high-speed cutting tools | Creating complex shapes, parts with tight tolerances |

| CNC Lathe Machines | Rotational machining operations | Producing cylindrical parts, shafts, rods, bushings |

| Drilling CNC Machines | Precision hole drilling | Aerospace, automotive, construction |

| Grinding CNC Machines | Precision grinding and polishing | Optics, jewelry, tool-making |

Types of CNC Machines by Number of Coordinate Axes

CNC machines come in various configurations, and one way to categorize them is by the number of coordinate axes they can travel. The number of axes a CNC machine has directly affects its complexity and capability to produce intricate parts. Let’s explore the different types of CNC machines based on their coordinate axes:

2-Axis CNC Machines

2-axis CNC machines operate in the X and Y axes, allowing movement horizontally and vertically. These machines excel at handling simple tasks like flat surface milling, drilling, and engraving. They are commonly used in applications that don’t require complex three-dimensional movements.

3-Axis CNC Machines

In addition to the X and Y axes, 3-axis CNC machines introduce a Z axis, enabling movement in depth. This extra axis allows for more versatile operations, such as creating three-dimensional shapes and contours. 3-axis CNC machines are widely used in industries like automotive, aerospace, and furniture manufacturing.

4-Axis CNC Machines

4-axis CNC machines enhance the capabilities of 3-axis machines by introducing an additional axis of rotation. With this added axis, these machines can perform tasks like indexing, milling helical shapes, and cutting irregular profiles. 4-axis CNC machines are commonly found in applications involving complex cylindrical or curved parts.

Multi-Axis CNC Machines

Multi-axis CNC machines, as the name suggests, can move in four or more directions. These machines provide unparalleled flexibility and precision, making them ideal for intricate and detailed machining processes. They can perform complex operations like simultaneous milling, turning, and drilling, allowing for the creation of highly intricate parts.

Having an understanding of the different types of CNC machines based on their coordinate axes is essential for selecting the right machine for specific manufacturing requirements. By choosing the appropriate CNC machine, manufacturers can enhance productivity, improve efficiency, and achieve high-quality results in their machining processes.

How to Choose a Good CNC Machine

When selecting a CNC machine for your project, it’s essential to consider several factors to ensure you make the right choice. By taking these factors into account, you can find a CNC machine that meets your requirements and helps you achieve your project’s goals.

Factors in Selecting a CNC Machine

1. Project Goals: Understand the specific needs of your project. Determine the type of machining processes and materials involved, as well as the desired level of precision and complexity. This will help you identify the right CNC machine that can fulfill your project requirements.

2. Cost: Consider your budget and the potential return on investment. Assess the long-term benefits that the CNC machine can bring to your business in terms of increased productivity, improved quality, and reduced labor costs.

3. Machine Weight: Evaluate the weight of the CNC machine, considering your available workspace and the machine’s portability. A heavy CNC machine may require a stable foundation, while a lighter one can be more easily maneuvered.

4. Power Rating: Determine the power requirements based on the materials you will be working with and the machining processes involved. Ensure that the CNC machine’s power rating is suitable for your intended applications.

“Choosing the right CNC machine is crucial for the success of your project. Consider the project goals, cost, machine weight, and power rating to make an informed decision.”

By carefully assessing these factors, you can select a CNC machine that aligns with your project requirements, budget, workspace, and power needs. Taking the time to choose the right CNC machine will ultimately contribute to the success and efficiency of your manufacturing operations.

Next, we will explore the importance of CNC machining in the manufacturing industry and examine the various industries that benefit from this technology.

Importance of CNC Machining

CNC machining plays a crucial role in the manufacturing industry, offering a wide range of benefits and significant advantages over traditional machining techniques. Its importance stems from its ability to produce accurate, repeatable, and affordable parts with exceptional precision and efficiency.

One of the key benefits of CNC machining is its ability to create intricate designs and precise mechanical components that would be challenging or costly to fabricate using other manufacturing methods. The computer-controlled precision of CNC machines enables the production of complex geometries, intricate patterns, and tight tolerances, ensuring the highest quality and consistency in the final products.

“CNC machining allows manufacturers to create intricate designs and precise mechanical components with exceptional precision and efficiency.”

Moreover, CNC machining offers unmatched versatility in terms of material options. It can work with a wide range of materials, including metals, plastics, composites, and even exotic materials like titanium and specialized alloys. This versatility makes CNC machining indispensable in various industries, from medical and electronics to aerospace and automotive.

CNC machining also provides remarkable cost savings and increased productivity. The automated nature of CNC machines eliminates the need for manual intervention, reducing labor costs and minimizing the risk of human error. Additionally, CNC machining allows for batch production, enabling manufacturers to produce large quantities of identical parts quickly and consistently.

The significance of CNC machining extends beyond its technical capabilities. It has revolutionized the manufacturing industry by enabling faster turnaround times and shorter lead times. This translates to improved customer satisfaction, as manufacturers can meet market demands more effectively and efficiently.

Benefits of CNC Machining:

- Accurate and precise production of complex designs

- Versatile material compatibility

- Cost savings through automation

- Increased productivity and efficiency

- Shorter lead times and improved customer satisfaction

In summary, the importance of CNC machining in the manufacturing industry cannot be overstated. Its ability to produce accurate, intricate, and cost-effective parts, coupled with its versatility and efficiency, makes it an indispensable technology in a wide range of industries.

Industries Benefiting from CNC Machining

Several industries benefit greatly from the widespread use of CNC machining. Let’s take a closer look at some of the key sectors that rely on CNC machining for their manufacturing processes:

1. Medical Industry

The medical sector utilizes CNC machining to manufacture precision equipment and components. CNC machining ensures the production of intricate and accurate medical devices, implants, prosthetics, and surgical instruments. The high level of precision offered by CNC machines is crucial in meeting the stringent requirements of the medical field.

2. Electronics Industry

In the electronics industry, CNC machining plays a vital role in producing intricate components and circuit boards. CNC machines can precisely cut, drill, and shape various materials used in electronic devices. With the ability to create complex designs and miniaturized components, CNC machining enables the manufacturing of high-quality electronics.

3. Aerospace Industry

The aerospace industry relies on CNC machining to create complex designs and precision parts for aircraft and spacecraft. CNC machines are used in the production of critical components such as turbine blades, engine parts, and airframe structures. The accuracy and reliability of CNC machining ensure the safety and performance of aerospace systems.

4. Automotive Industry

CNC machining plays a significant role in the automotive industry, where it is used for manufacturing various parts and components. From engine components to interior features, CNC machines enable the production of high-quality parts with tight tolerances. The automotive industry benefits from CNC machining’s ability to deliver consistent and repeatable results.

Other industries that extensively utilize CNC machining include publishing, woodworking, construction, agriculture, and metalwork. CNC machining offers these sectors the precision, efficiency, and versatility required for their specific manufacturing applications.

How CNC Machining is Used

CNC machining is a versatile and efficient process that finds applications in various industries. It plays a crucial role in controlling machinery like grinders, lathes, and mills, enabling precise and accurate production. One of the key uses of CNC machining is in the creation of molds and machined metal parts. By utilizing computer-controlled cutting tools and high-quality materials, CNC machining ensures the production of intricate designs with exceptional precision.

The applications of CNC machining extend across industries such as automotive, aerospace, electronics, and medical. In the automotive industry, CNC machining is employed to manufacture parts with complex geometries, ensuring optimal performance and safety. In aerospace, CNC machining is used to create intricate components that meet strict quality and reliability standards. The electronics industry utilizes CNC machining for precise fabrication of intricate circuit boards and other electronic components. Additionally, CNC machining finds extensive use in the medical industry for producing precision equipment and implants.

CNC machining offers several advantages over traditional manufacturing processes. It allows for faster production, increased efficiency, and reduced human error. The computer-controlled nature of CNC machines ensures consistent and repeatable results, leading to improved product quality. Moreover, CNC machining processes can handle a wide range of materials, including metals, plastics, and composites, further expanding their applications in manufacturing.

In conclusion, CNC machining is a highly valuable technology with diverse applications. It provides the capability to produce intricate and precise designs, making it indispensable in industries that demand high-quality, complex components. With its versatility, efficiency, and accuracy, CNC machining continues to revolutionize modern manufacturing processes and drive advancements in various sectors.