What are the 7 different types of machining tools?

Machining tools are tools used to shape and cut materials such as metal, wood, and plastic. There are seven main types of machining tools:

1. Drilling Tools: Drilling tools are used to create holes in materials. They come in a variety of shapes and sizes and can be used for a variety of applications. Common types of drilling tools include twist drills, reamers, and taps.

2. Milling Tools: Milling tools are used to shape and cut materials. They come in a variety of shapes and sizes and can be used for a variety of applications. Common types of milling tools include end mills, face mills, and slot drills.

3. Turning Tools: Turning tools are used to shape and cut materials. They come in a variety of shapes and sizes and can be used for a variety of applications. Common types of turning tools include lathes, chucks, and mandrels.

4. Grinding Tools: Grinding tools are used to shape and cut materials. They come in a variety of shapes and sizes and can be used for a variety of applications. Common types of grinding tools include grinding wheels, abrasive stones, and abrasive belts.

5. Sawing Tools: Sawing tools are used to shape and cut materials. They come in a variety of shapes and sizes and can be used for a variety of applications. Common types of sawing tools include hacksaws, band saws, and jigsaws.

6. Shaping Tools: Shaping tools are used to shape and cut materials. They come in a variety of shapes and sizes and can be used for a variety of applications. Common types of shaping tools include files, rasps, and chisels.

7. Finishing Tools: Finishing tools are used to shape and cut materials. They come in a variety of shapes and sizes and can be used for a variety of applications. Common types of finishing tools include sanders, polishers, and buffers.

What is VMC machine?

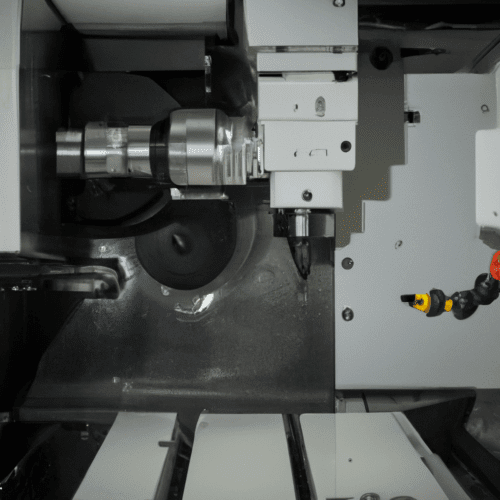

A VMC machine, or Vertical Machining Center, is a type of computer numerical control (CNC) machine tool that uses computer-controlled processes to shape and cut materials. It is a type of machining center that is designed to perform a variety of operations, including drilling, milling, tapping, and boring. The VMC machine is typically used for high-precision machining operations, and is capable of producing complex parts with tight tolerances.

The VMC machine is composed of several components, including a spindle, a table, a tool changer, and a control system. The spindle is the main component of the machine, and is responsible for rotating the cutting tool. The table is used to hold the workpiece in place, and is typically made of cast iron or steel. The tool changer is used to change the cutting tool, and is typically automated. The control system is responsible for controlling the machine’s movements, and is typically a computer numerical control (CNC) system.

What are the 6 most common CNC machines?

The six most common CNC machines are lathes, milling machines, laser cutters, plasma cutters, EDM machines, and waterjet cutters.

Lathes are used to shape metal, wood, and other materials by spinning them at high speeds and cutting them with a cutting tool. They are used to create cylindrical parts, such as screws, bolts, and other fasteners.

Milling machines are used to shape metal, wood, and other materials by cutting them with a rotating cutting tool. They are used to create flat surfaces, slots, and other shapes.

Laser cutters use a laser beam to cut materials such as metal, wood, and plastic. They are used to create intricate shapes and patterns.

Plasma cutters use a high-temperature plasma arc to cut materials such as metal, wood, and plastic. They are used to create intricate shapes and patterns.

How many axis are there in VMC machine?

A VMC (Vertical Machining Center) is a type of CNC (Computer Numerical Control) machine tool that uses computerized controls to operate machine tools such as lathes, mills, and grinders. VMCs are typically used for machining complex parts with tight tolerances and high precision. The number of axes in a VMC machine can vary depending on the type of machine and the application. Generally, VMCs have three linear axes (X, Y, and Z) and one rotary axis (A). The X-axis is the left-right movement of the cutting tool, the Y-axis is the front-back movement of the cutting tool, and the Z-axis is the up-down movement of the cutting tool. The A-axis is the rotary axis that allows the cutting tool to rotate around the part. Some VMCs may also have additional axes such as a B-axis, which allows the cutting tool to tilt, or a C-axis, which allows the part to rotate.

What are 3 types of CNC machines?

CNC machines are computer-controlled machines used for cutting, drilling, grinding, and other manufacturing processes. There are three main types of CNC machines: milling machines, lathes, and routers.

Milling machines are used to cut and shape metal and other materials. They use a rotating cutting tool to remove material from the workpiece. The cutting tool is usually a drill bit, end mill, or face mill. Milling machines can be used to create complex shapes and contours, as well as to drill holes and create slots.

Lathes are used to shape metal and other materials by rotating them against a cutting tool. The cutting tool is usually a single-point cutting tool, such as a drill bit, chisel, or reamer. Lathes can be used to create complex shapes and contours, as well as to drill holes and create slots.

Routers are used to cut and shape wood and other materials. They use a rotating cutting tool to remove material from the workpiece.

What are 3 types of CNC machines?

CNC machines are computer-controlled machines used in manufacturing to cut and shape materials. There are three main types of CNC machines: milling machines, lathes, and routers.

Milling machines are used to cut and shape materials such as metal, wood, and plastic. They use a rotating cutting tool to remove material from the workpiece. The cutting tool is moved in three directions (X, Y, and Z) to create the desired shape. Milling machines can be used to create complex shapes and contours, as well as drill holes and slots.

Lathes are used to shape materials such as metal, wood, and plastic. They use a rotating cutting tool to remove material from the workpiece. The cutting tool is moved in two directions (X and Z) to create the desired shape. Lathes can be used to create cylindrical shapes, as well as drill holes and slots.

Routers are used to cut and shape materials such as metal, wood, and plastic. They use a rotating cutting tool to remove material from the workpiece.

Why is CNC important?

Computer Numerical Control (CNC) is a technology that has revolutionized the manufacturing industry. CNC is a process that uses computer-controlled machines to automate the production of parts and components. It is used in a variety of industries, including aerospace, automotive, medical, and consumer products.

CNC is important because it allows for greater precision and accuracy in the production of parts and components. CNC machines are programmed with a set of instructions that tell the machine how to move and what to do. This eliminates the need for manual labor and allows for greater accuracy and repeatability in the production process. CNC machines can also be programmed to produce parts with complex shapes and intricate details that would be difficult or impossible to produce with traditional methods.

CNC is also important because it allows for faster production times. CNC machines can produce parts and components in a fraction of the time it would take to produce them manually. This allows manufacturers to produce more parts in a shorter amount of time, which can lead to increased efficiency and cost savings.

What are 5 different materials that can be used on a CNC machine?

1. Aluminum: Aluminum is a lightweight, corrosion-resistant metal that is often used in CNC machining. It is easy to machine and can be used to create complex shapes and intricate details. It is also relatively inexpensive and can be used for a variety of applications.

2. Steel: Steel is a strong and durable metal that is often used in CNC machining. It is more difficult to machine than aluminum, but it is also more resistant to wear and tear. Steel is often used for parts that require high strength and durability.

3. Brass: Brass is a malleable metal that is often used in CNC machining. It is easy to machine and can be used to create intricate details and complex shapes. Brass is also relatively inexpensive and can be used for a variety of applications.

4. Plastic: Plastic is a lightweight and durable material that is often used in CNC machining. It is easy to machine and can be used to create complex shapes and intricate details. Plastic is also relatively inexpensive and can be used for a variety of applications.

What is the difference between CNC turning and CNC milling?

CNC (Computer Numerical Control) turning and CNC milling are both forms of subtractive manufacturing, meaning that material is removed from a workpiece to create a desired shape. The primary difference between CNC turning and CNC milling is the way in which the workpiece is held and rotated. In CNC turning, the workpiece is held in a chuck and rotated while a cutting tool is fed into the rotating workpiece. This process is used to create cylindrical parts with smooth finishes. In CNC milling, the workpiece is held stationary while the cutting tool is moved in multiple axes to create the desired shape. This process is used to create complex shapes with precise dimensions.

CNC turning is generally used for parts that require a high degree of accuracy and surface finish, such as shafts, pins, and bushings. CNC milling is used for parts that require complex shapes and precise dimensions, such as engine blocks and molds.

Is a 3D printer a CNC machine?

No, a 3D printer is not a CNC machine. A 3D printer is a type of additive manufacturing technology that creates three-dimensional objects by building them up layer by layer from a digital file. It works by depositing material, such as plastic, metal, or ceramic, in successive layers to create a three-dimensional object. On the other hand, a CNC machine is a type of subtractive manufacturing technology that uses computer-controlled tools to shape a material by cutting away excess material. CNC machines are typically used to create parts for industrial machinery, such as car parts, medical equipment, and aerospace components. While both 3D printing and CNC machining are used to create parts, they are two distinct processes that use different technologies.

Is lathe a CNC machine?

No, a lathe is not a CNC machine. A lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, or deformation. It is used to shape a variety of materials, including metal, wood, and plastic. A CNC machine, on the other hand, is a computer-controlled machine that uses a computer program to control the movement of the machine’s tools. CNC machines are used to create precision parts and components with a high degree of accuracy and repeatability. CNC machines are used in a variety of industries, including automotive, aerospace, medical, and electronics.

What is the most popular CNC machine?

The most popular CNC machine is the Computer Numerical Control (CNC) milling machine. CNC milling machines are used to create parts with complex shapes and features from a variety of materials, including metals, plastics, and composites. CNC milling machines are highly precise and can produce parts with tight tolerances. They are also capable of producing parts with complex geometries, such as curved surfaces, and can be used to create parts with intricate details. CNC milling machines are used in a variety of industries, including automotive, aerospace, medical, and consumer products. They are also used in the production of precision parts for industrial machinery. CNC milling machines are available in a variety of sizes and configurations, and can be customized to meet the specific needs of the user. CNC milling machines are typically operated by a computer program, which allows for the precise control of the machine’s movements. This allows for the production of parts with high accuracy and repeatability.

How many different types of CNC machines are there?

There are many different types of CNC machines, each designed for a specific purpose. The most common types of CNC machines are milling machines, lathes, routers, grinders, and EDM (electrical discharge machining) machines.

Milling machines are used to cut and shape metal and other materials. They use a rotating cutting tool to remove material from the workpiece. Lathes are used to shape metal and other materials by rotating the workpiece while a cutting tool is applied to it. Routers are used to cut and shape wood and other materials. They use a rotating cutting tool to remove material from the workpiece. Grinders are used to shape and finish metal and other materials. They use a rotating grinding wheel to remove material from the workpiece. EDM machines are used to cut and shape metal and other materials using electrical discharges.

In addition to these common types of CNC machines, there are also specialty machines such as laser cutters, plasma cutters, waterjet cutters, and wire EDM machines.

Can a CNC machine drill holes?

Yes, a CNC machine can drill holes. CNC stands for Computer Numerical Control, and it is a type of automated machine that is used to perform a variety of tasks, including drilling holes. CNC machines are programmed with a set of instructions that tell the machine how to move and what operations to perform. This programming can be used to create a variety of shapes and sizes of holes, as well as other operations such as cutting, milling, and grinding.

CNC machines are used in a variety of industries, including automotive, aerospace, and medical. They are used to create precision parts and components, as well as to create complex shapes and patterns. CNC machines are also used to create custom parts and components for a variety of applications.

When drilling holes with a CNC machine, the machine is programmed with the size and shape of the hole that needs to be drilled. The machine then moves the drill bit in a precise pattern to create the desired hole.

What metals can CNC cut?

CNC (Computer Numerical Control) cutting is a process used to cut a variety of materials, including metals. The type of metal that can be cut with a CNC machine depends on the type of machine and the cutting tool used. Generally, CNC machines can cut a wide range of metals, including aluminum, brass, copper, steel, stainless steel, and titanium.

Aluminum is one of the most commonly cut metals with CNC machines. It is lightweight, strong, and corrosion-resistant, making it ideal for a variety of applications. Aluminum can be cut with a variety of tools, including end mills, drills, and routers.

Brass is another metal that can be cut with a CNC machine. It is a strong and durable metal that is often used in the manufacturing of parts for machines and other equipment. Brass can be cut with a variety of tools, including end mills, drills, and routers.

Copper is a soft metal that can be cut with a CNC machine. It is often used in the manufacturing of electrical components and wiring.

Can you CNC mill steel?

Yes, it is possible to CNC mill steel. CNC milling is a machining process that uses computer numerical control (CNC) to control the movement of the cutting tool. CNC milling is a subtractive manufacturing process, meaning that material is removed from the workpiece to create the desired shape. Steel is a commonly used material in CNC milling, as it is strong and durable and can be machined to precise tolerances.

When CNC milling steel, the cutting tool must be made of a material that is harder than the material being machined. This is because the cutting tool must be able to withstand the high temperatures and pressures generated during the machining process. Commonly used cutting tools for CNC milling steel include high-speed steel (HSS) and carbide.

The cutting speed, feed rate, and depth of cut must all be carefully considered when CNC milling steel. The cutting speed should be kept as low as possible to reduce heat buildup and minimize tool wear.