CNC turning is a precision machining process that uses computer-controlled lathes to create cylindrical parts with high accuracy. In this process, a cutting tool removes material from a rotating workpiece to produce the desired shape and dimensions. The CNC (Computer Numerical Control) system directs the lathe’s movements based on programmed instructions, allowing for complex geometries and tight tolerances. As the workpiece spins, the cutting tool moves along various axes, typically X and Z, to perform operations such as facing, tapering, grooving, and threading.

CNC turning can handle a wide range of materials, including metals, plastics, and composites, making it versatile for industries like aerospace, automotive, and medical device manufacturing. The process offers advantages such as repeatability, efficiency, and the ability to produce intricate features that would be challenging or impossible with manual turning. Advanced CNC turning centers may incorporate additional features like live tooling, multiple spindles, or Y-axis capabilities, further expanding the range of possible operations and reducing the need for secondary machining processes.

- CNC turning is a computer-controlled manufacturing process that removes material from a cylindrical stock to create a desired shape.

- A CNC lathe machine is used to rotate the workpiece while a cutting tool removes excess material.

- CNC turning offers advanced precision and repeatability, making it ideal for creating complex parts.

- It is commonly used in industries such as woodworking, electrical, automotive, and material fabrication.

- CNC turning can work with a wide range of materials, including metals, wood, plastics, and polymers.

The Difference Between CNC Milling and Turning

While CNC milling and turning are both CNC machining processes, they have distinct differences that make each suitable for specific applications. Understanding these differences is crucial for determining the most appropriate machining technique for your project.

CNC Milling:

CNC milling involves the use of rotating multi-point cutting tools to progressively remove material from a stationary workpiece. This process is ideal for precise shaping and complex design options. Here are some key features and advantages of CNC milling:

- Conserving Material: CNC milling is known for its ability to efficiently conserve material, resulting in cost savings and less waste.

- Versatile Design Options: Complex designs can be easily achieved with CNC milling due to its exceptional maneuverability and flexibility.

- Prototyping and Small Production Runs: CNC milling is particularly suitable for prototyping and smaller production runs.

CNC Turning:

CNC turning, on the other hand, rotates the workpiece while feeding a single-point cutting tool into the material. This enables faster operations and the creation of cylindrical shapes. Here are some key features and advantages of CNC turning:

- Fast Production Times: CNC turning offers faster production times compared to CNC milling, making it ideal for large production runs with shorter lead times.

- Complex Designs: While CNC turning is primarily used for cylindrical shapes, it still allows for intricate design options such as grooving and threading.

- Enhanced Strength: The rotary nature of CNC turning creates parts with excellent strength and durability.

Overall, the choice between CNC milling and turning depends on the specific requirements of your project. If you need intricate shapes and complex designs, CNC milling is the preferred method. On the other hand, if you require fast production times and cylindrical shapes, CNC turning is the way to go.

CNC Turning Process Explained

In the world of manufacturing, CNC turning is a revolutionary process that delivers precise and efficient machining results. Understanding the CNC turning process is essential for those looking to harness the advantages of this cutting-edge technology.

The CNC turning process begins with a crucial component known as the chuck. The chuck securely holds the workpiece, allowing for precise rotation during machining. This rotation enables the cutting tool to smoothly and accurately remove material from the workpiece.

The key concept behind CNC turning is subtraction machining. As the workpiece rotates, the cutting tool is fed into the material to remove excess material and shape it according to the desired specifications. This method ensures precision and consistency, delivering high-quality results.

In some turning centers, there are additional features like the main spindle and sub-spindle. The main spindle is responsible for partially machining the workpiece, while the sub-spindle takes over to complete the job on the other side of the part. This setup enhances efficiency, allowing for even faster operation and reduced production times.

Overall, the CNC turning process combines the power of chuck rotation and subtraction machining to deliver exceptional machining results. It offers a level of precision and repeatability that is unparalleled, making it a preferred choice for various industries.

CNC Turning Applications and Materials

CNC turning is a versatile manufacturing process used in various industries and applications. It is particularly valuable in woodworking, where it enables the creation of custom-designed parts and components. In the electrical industry, CNC turning plays a vital role in operations such as boring, drilling, facing, and grooving. Moreover, CNC turning is widely employed in the automotive and manufacturing sectors for efficient metal removing operations. The process is also utilized in material fabrication, allowing for the creation of precision components and prototype parts.

CNC turning can work with a wide range of materials, further enhancing its applicability. Metals like aluminum, copper, and steel are commonly used in CNC turning processes, catering to the requirements of industries such as automotive and manufacturing. Additionally, CNC turning can effectively handle non-metallic materials, including wood, plastics, and various polymers, which are extensively utilized in woodworking and material fabrication. This flexibility in material options makes CNC turning a preferred choice for diverse industries and manufacturing needs.

The application and material versatility of CNC turning demonstrates its effectiveness in meeting the demands of different industries, providing precise and efficient material fabrication solutions.

Production Capabilities of CNC Milling and Turning

CNC milling and turning offer unique production capabilities that cater to different manufacturing needs. CNC milling, known for its exceptional material conservation efficiency, allows for reduced material costs over the lifespan of the machine. This process is widely used for fabricating complex short-run production parts, precision components, and prototype parts. By precisely removing material from a stationary workpiece using rotating cutting tools, CNC milling delivers precise and intricate shapes.

On the other hand, CNC turning stands out for its efficiency in large production runs with tight lead times. It excels in operations such as boring, drilling, facing, grooving, knurling, and parting. With CNC turning, the workpiece rotates while a cutting tool removes material, allowing for faster production times. CNC turning is commonly utilized for creating precision components and prototype parts, meeting the demand for speedy production.

Both CNC milling and turning processes contribute to the manufacturing industry by providing tailored solutions for various production requirements. While CNC milling brings cost-effective material conservation and precise shaping capabilities, CNC turning offers speed and efficiency in large-scale production.

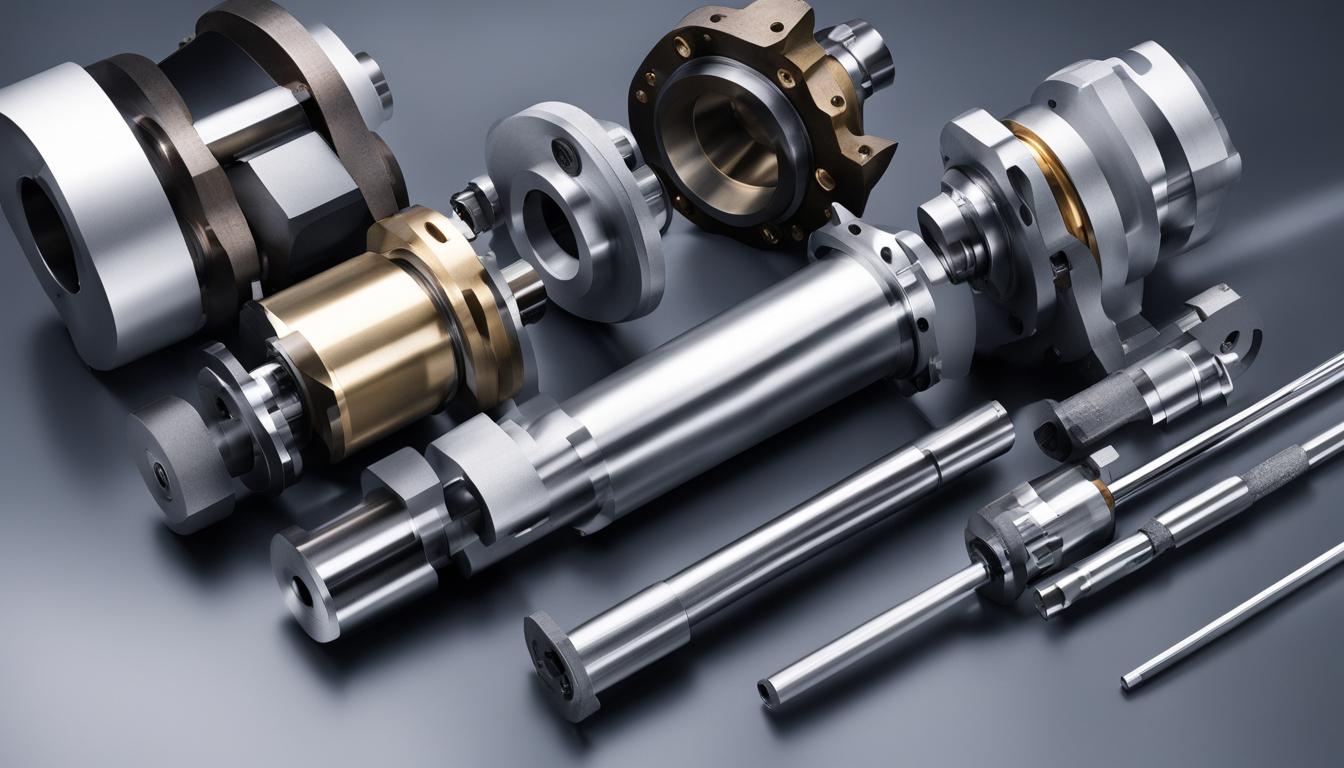

Components of a CNC Turning Machine

A CNC turning machine is comprised of several integral components that work together to perform precise machining operations. These components include the spindle, chuck, tool holders, and turret.

The spindle is a vital part of the machine drive system and is responsible for rotating the workpiece during the turning process. It provides the necessary power and speed to effectively remove material from the workpiece.

The chuck is typically equipped with three or four jaws and is used to securely grip and hold the workpiece in place. Its robust design ensures stability and accuracy during machining, preventing any unwanted movement or vibration.

Tool holders are crucial for holding and positioning the cutting tools used in CNC turning. They are securely bolted onto the turret, which can rotate and move the tools into the correct position for different machining operations. The turret is controlled by computer programs and codes, allowing for automated tool changes and precise tool positioning.

The combination of these components in a CNC turning machine enables the automated and precise machining of complex parts, providing manufacturers with efficiency and accuracy in their production processes.

| Components | Description |

|---|---|

| Spindle | Attached to the machine drive system; rotates the workpiece |

| Chuck | Grips and holds the workpiece securely during machining |

| Tool Holders | Hold cutting tools and are bolted to the turret |

| Turret | Rotates and positions the tools for different machining operations |

Common Turning Operations in CNC Turning

In CNC turning, there are several common operations that can be performed. These operations play a crucial role in shaping the workpiece and creating the desired end product. Let’s explore each of these operations.

Facing

Facing is the process of cutting a flat surface perpendicular to the rotational axis of the workpiece. This operation is often used to create precise and smooth end faces on cylindrical parts. It helps ensure that the workpiece has a clean and level surface.

Turning

Turning is one of the fundamental operations in CNC turning. It involves removing material from the outer diameter of the workpiece to create a desired shape. Turning can be used to create intricate details, contours, and different types of profiles on the workpiece. This operation allows for precision and accuracy in shaping the part.

Drilling

Drilling is a common operation used in CNC turning to create holes in the workpiece. The drilling operation is performed by feeding a rotating drill bit into the material, resulting in a hole with a consistent diameter. It is essential for creating holes for various applications and components.

Boring

Boring is another important operation in CNC turning that is used to enlarge existing holes in the workpiece. This operation helps achieve precise dimensions and tolerances while ensuring a smooth and accurately sized hole. Boring is often used in conjunction with other operations to create complex features.

Threading

Threading is the process of cutting threads on the workpiece. It is commonly used to create internal or external screw threads, allowing for the assembly of threaded components. Threading is crucial for applications where a secure and tight connection is required.

Grooving

Grooving in CNC turning involves creating grooves or features on the workpiece. Grooves can serve various purposes, such as accommodating O-rings for sealing or providing clearance for other components. CNC turning allows for precise grooving, ensuring the desired dimensions and specifications are met.

Knurling

Knurling is a unique operation in CNC turning that is used to create a diamond pattern on the outer diameter of the part. This pattern provides an enhanced grip, making it easier to handle and manipulate the finished part. Knurling is often applied to applications where added grip and aesthetic appeal are desired.

These common turning operations in CNC turning enable manufacturers to create intricate and precise parts with ease. By leveraging the capabilities of CNC turning machines, manufacturers can achieve high-quality results and meet the specific requirements of their customers.

Advantages of CNC Turning

CNC turning offers several advantages over traditional turning methods. The automated nature of CNC turning ensures high accuracy and precision in producing parts. By utilizing computer-controlled machines, CNC turning eliminates human error, resulting in consistently precise outcomes. This level of accuracy is especially crucial for industries that demand exact specifications, such as aerospace or medical manufacturing.

Another significant advantage of CNC turning is its flexibility. CNC turning centers can perform a wide range of operations, including milling and drilling, in addition to the primary turning process. This versatility allows manufacturers to create complex shapes and features on the workpiece, expanding the possibilities for innovative designs and reducing the need for multiple machines or manual operations.

Safety is another critical factor when it comes to CNC turning. With traditional turning methods, operators are in close proximity to the rotating material, which poses various risks. CNC turning machines, on the other hand, have built-in safety measures that protect operators from potential accidents. The process is automated, eliminating the need for direct contact with moving parts and reducing the risk of injury.

Furthermore, CNC turning offers faster results compared to traditional methods. The continuous nature of the process allows for uninterrupted production, resulting in shorter lead times and increased productivity. Additionally, tool changes in CNC turning can be done quickly, minimizing downtime and maximizing efficiency.

| Advantages | Description |

|---|---|

| Accuracy | CNC turning ensures high precision and eliminates human error. |

| Flexibility | CNC turning centers can perform various operations, expanding design possibilities. |

| Safety | CNC turning machines have built-in safety measures, reducing risks for operators. |

| Faster Results | Continuous production and fast tool changes result in shorter lead times. |

CNC Turning and Material Science

Material science plays a crucial role in CNC turning, a highly precise and efficient manufacturing process. One key aspect is the use of tool inserts made of carbide, which greatly impact performance. These inserts are carefully designed in terms of composition and structure to ensure optimal results.

One important factor in tool insert design is crystal orientation. Technologies like Sandvik’s Inveio® enable the creation of a unidirectional crystal structure in carbide inserts. This innovative approach enhances wear resistance and prolongs the tool’s lifespan, leading to improved efficiency and reduced machining costs.

When selecting the right insert for CNC turning, considering the material being machined is crucial. Different materials have different characteristics and require specific tool inserts for optimal performance. By choosing the appropriate insert, machinists can achieve superior results in terms of precision, productivity, and cost-effectiveness.