Milling and turning are two common machining processes used in the manufacturing industry. Milling is a machining process that uses a rotating cutting tool to remove material from a workpiece. The cutting tool is fed into the workpiece in a linear direction, and the material is removed in the form of chips. Milling is typically used to produce flat surfaces, slots, grooves, and other features on the workpiece.

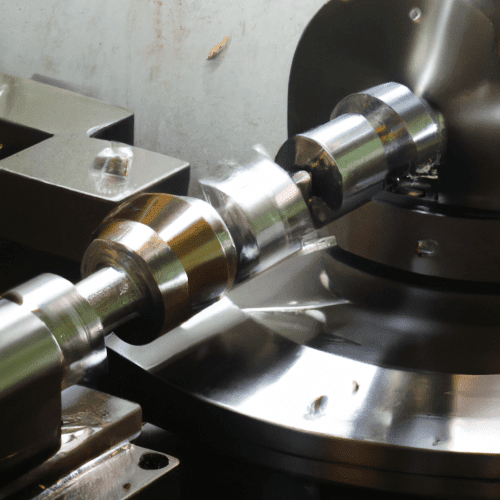

Turning is a machining process that uses a single-point cutting tool to remove material from a rotating workpiece. The cutting tool is fed into the workpiece in a radial direction, and the material is removed in the form of chips. Turning is typically used to produce cylindrical parts, such as shafts, pins, and bushings.

The main difference between milling and turning is the direction in which the cutting tool is fed into the workpiece. In milling, the cutting tool is fed into the workpiece in a linear direction, while in turning, the cutting tool is fed into the workpiece in a radial direction. Additionally, milling

What is the difference between milling drilling and turning?

Milling, drilling, and turning are all machining processes used to shape and finish materials. Milling is a machining process that uses a rotating cutting tool to remove material from a workpiece. The cutting tool is moved in a linear direction, and the workpiece is moved in a rotary direction. Milling is used to create flat surfaces, slots, grooves, and other features on the workpiece. Drilling is a machining process that uses a rotating cutting tool to create a hole in a workpiece. The cutting tool is moved in a linear direction, and the workpiece is held stationary. Drilling is used to create holes in the workpiece. Turning is a machining process that uses a rotating cutting tool to shape the outside of a workpiece. The cutting tool is moved in a rotary direction, and the workpiece is held stationary. Turning is used to create cylindrical shapes, such as shafts, spindles, and other features on the workpiece.

What is difference between turn mill and mill turn?

The main difference between turn mill and mill turn is the type of machine used to produce the parts. Turn mill is a type of machine that uses a lathe to produce parts, while mill turn is a type of machine that uses a milling machine to produce parts.

Turn mill machines are typically used for producing parts with a high degree of accuracy and repeatability. This is because the lathe is able to precisely control the cutting tool and the workpiece, allowing for a high degree of accuracy and repeatability. The lathe is also able to produce parts with complex shapes and contours, as well as parts with intricate details.

Mill turn machines, on the other hand, are typically used for producing parts with a lower degree of accuracy and repeatability. This is because the milling machine is not as precise as the lathe, and is not able to produce parts with complex shapes and contours. However, mill turn machines are able to produce parts with intricate details, as well as parts with a high degree of accuracy and repeatability.

Why is milling better than turning?

Milling is a machining process that uses a rotating multi-point cutting tool to remove material from a workpiece. It is generally considered to be more versatile than turning, as it is capable of cutting a wider variety of materials in a variety of shapes and sizes. Milling is also capable of producing complex shapes with a high degree of accuracy, which is not possible with turning. Additionally, milling can be used to create a variety of features, such as slots, grooves, and pockets, which are not possible with turning.

Milling is also more efficient than turning, as it is capable of cutting multiple pieces of material at once. This is due to the fact that the cutting tool is able to move in multiple directions, allowing it to cut multiple pieces of material simultaneously. Additionally, milling is capable of producing parts with a higher degree of accuracy than turning, as the cutting tool is able to move in multiple directions, allowing it to cut more precisely.

What is the turning process?

The turning process is a machining operation used to create cylindrical parts with a consistent diameter and shape. It is a subtractive manufacturing process, meaning that material is removed from a workpiece to create the desired shape. The turning process is typically used to create parts with a high degree of accuracy and surface finish.

The turning process begins with a workpiece, which is typically a cylindrical piece of metal, but can also be made of other materials such as wood or plastic. The workpiece is then mounted in a lathe, which is a machine tool that rotates the workpiece while a cutting tool is used to remove material from the workpiece. The cutting tool is typically a single-point cutting tool, which is a tool with a single cutting edge. The cutting tool is moved along the length of the workpiece in a linear motion, while the workpiece is rotated. This process is known as turning.

The turning process can be used to create a variety of shapes, including straight, tapered, and contoured shapes.

What is the main difference between the lathe and milling machine?

The main difference between a lathe and a milling machine is the way in which they cut materials. A lathe spins the material while a fixed cutting tool is applied to the material, removing material in the form of chips. A milling machine, on the other hand, uses a rotating cutting tool to remove material from the workpiece. The cutting tool is moved in various directions to shape the material into the desired form.

Lathes are typically used to shape cylindrical objects, while milling machines are used to shape flat and irregular surfaces. Lathes are also used to create threads, while milling machines are used to create slots, grooves, and other complex shapes. Lathes are generally used for smaller, more precise work, while milling machines are used for larger, more complex projects. Lathes are also capable of producing a variety of shapes, while milling machines are limited to producing shapes that are perpendicular to the axis of rotation.

What is turning in CNC?

Turning in CNC (Computer Numerical Control) is a machining process used to create parts with cylindrical features. It is a subtractive manufacturing process, meaning that material is removed from a solid block of material to create the desired shape. The process is controlled by a computer program that tells the machine what to do. The program is written in a language called G-code, which is a set of instructions that tells the machine how to move and what tools to use.

The process begins with a solid block of material, usually metal, that is mounted on a spindle. The spindle is then rotated at a high speed and a cutting tool is used to remove material from the block. The cutting tool is usually a single-point cutting tool, but can also be a multi-point cutting tool. The cutting tool is moved in a linear direction along the block of material, and the spindle is rotated to create the desired shape. The cutting tool is moved in a precise manner, and the speed and depth of the cut can be controlled by the computer program.

What is the difference between CNC and lathe?

The primary difference between CNC (Computer Numerical Control) and lathe is the way in which they are operated. CNC machines are operated by a computer program that is programmed to control the machine’s movements and operations. This allows for a much higher level of precision and accuracy than a lathe, which is operated manually. CNC machines are also able to produce more complex shapes and designs than a lathe, as the computer program can be programmed to create intricate patterns and shapes.

CNC machines are also much faster than lathes, as the computer program can be programmed to repeat the same operation multiple times in a short period of time. This allows for a much higher level of production than a lathe, which is limited by the speed of the operator. CNC machines are also much more expensive than lathes, as they require a computer program and specialized software to operate.

In terms of materials, CNC machines are able to work with a wide variety of materials, including metals, plastics, and composites.

Is turning cheaper than milling?

The answer to this question depends on a variety of factors, including the type of material being machined, the complexity of the part, the size of the part, and the accuracy required. Generally speaking, turning is usually cheaper than milling for simple parts that are relatively small and require only basic accuracy. This is because turning is a simpler process that requires less setup time and fewer tools than milling. However, for more complex parts that require higher accuracy, milling may be the more cost-effective option. Milling also tends to be more cost-effective for larger parts, as the setup time and tooling costs are spread out over a larger part. Ultimately, the cost of turning versus milling will depend on the specific requirements of the part being machined.

What is a CNC milling machine used for?

A CNC (Computer Numerical Control) milling machine is a type of machining tool used for precision machining of metal and other materials. It is a computer-controlled machine that uses a cutting tool to remove material from a workpiece in a precise manner. CNC milling machines are used in a variety of industries, including aerospace, automotive, medical, and electronics.

CNC milling machines are used to create a variety of parts, from simple to complex shapes. They are used to create components for a variety of products, including aircraft, automobiles, medical devices, and consumer electronics. CNC milling machines are capable of producing parts with tight tolerances and intricate details. They are also used to create molds and dies for injection molding and die casting.

CNC milling machines are used to create a variety of shapes, including flat surfaces, curved surfaces, and complex 3D shapes. They are also used to create slots, grooves, and other features. CNC milling machines are capable of producing parts with high accuracy and repeatability.