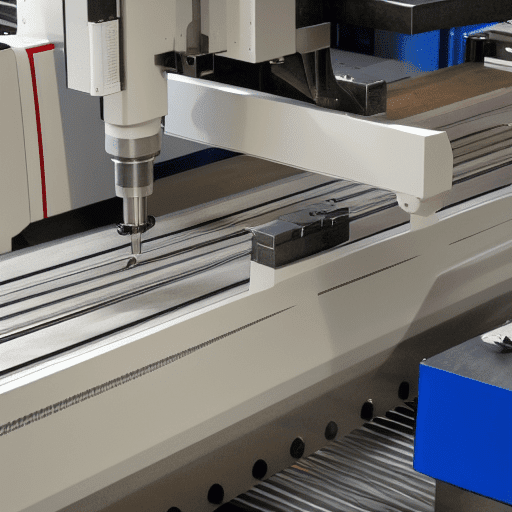

CNC machining is a process that uses computer numerical control (CNC) machines to shape and cut materials into a desired shape or size. It is a highly precise and automated process that can produce complex parts with a high degree of accuracy and repeatability.

Advantages of CNC Machining:

1. High Precision: CNC machining is capable of producing parts with extremely high precision and accuracy. This is due to the fact that the machines are programmed with exact specifications and the cutting tools are guided by the computer. This allows for parts to be produced with very tight tolerances and repeatability.

2. Cost-Effective: CNC machining is a cost-effective process as it requires less labor and fewer tools than traditional machining processes. This makes it ideal for producing large quantities of parts quickly and efficiently.

3. Versatility: CNC machining is a versatile process that can be used to produce a wide variety of parts from a variety of materials. This makes it ideal for producing complex parts with intricate shapes and features.

Disadvantages of CNC Machining:

1. High Initial Investment: CNC machining requires a high initial investment in terms of the machines and software. This can be a barrier for small businesses or those just starting out.

2. Limited Materials: CNC machining is limited to certain materials such as metals and plastics. This can be a limitation for those looking to produce parts from other materials.

3. Complex Programming: CNC machining requires complex programming in order to produce the desired parts. This can be a barrier for those without the necessary programming skills.

Limitations of CNC Machining:

1. Complex Geometries: CNC machining is limited in its ability to produce complex geometries. This is due to the fact that the machines are limited in their ability to move in certain directions.

2. Time-Consuming: CNC machining can be a time-consuming process as the machines must be programmed and set up for each part. This can be a limitation for those looking to produce parts quickly.

What is CNC milling advantages and disadvantages?

CNC (Computer Numerical Control) milling is a process used in the manufacturing industry that employs computerized controls to operate and manipulate machine tools like lathes, mills, and grinders. CNC milling has several advantages over traditional manual milling, including increased precision, improved accuracy, increased productivity, and improved safety.

Advantages of CNC Milling

One of the primary advantages of CNC milling is increased precision. CNC machines are able to produce parts with tighter tolerances than manual machines, which can result in improved product quality and reduced scrap. CNC machines are also able to produce parts with a higher degree of accuracy than manual machines, which can result in improved product performance.

CNC milling also offers increased productivity. CNC machines are able to produce parts faster than manual machines, which can result in reduced lead times and improved customer satisfaction. CNC machines are also able to produce parts with a higher degree of complexity than manual machines, which can result in improved product design.

What are the disadvantages of machining?

Machining is a process that involves cutting and shaping materials to create a desired product. While it is a very useful and versatile process, there are some disadvantages associated with it.

One of the main disadvantages of machining is the cost. Machining is a labor-intensive process that requires specialized tools and equipment, which can be expensive to purchase and maintain. Additionally, the cost of labor for machining can be high, as it requires skilled workers to operate the machines.

Another disadvantage of machining is the time it takes to complete a job. Machining is a slow process, as it requires precise and accurate cuts to be made. This can lead to long lead times for projects, which can be a problem for businesses that need to meet tight deadlines.

Machining also produces a lot of waste material. This is because the process involves cutting away material to create the desired shape, which results in a lot of scrap material. This can be costly for businesses, as they have to pay for the scrap material as well as the cost of disposing of it.

What is not the advantage of CNC machine?

One of the main disadvantages of CNC machines is their high cost. CNC machines are more expensive than traditional machines, and the cost of purchasing and maintaining them can be prohibitive for some businesses. Additionally, CNC machines require a significant amount of training and expertise to operate, which can be difficult to find and expensive to acquire. Furthermore, CNC machines are not as versatile as traditional machines, as they are limited to the specific tasks they are programmed to do. Finally, CNC machines are not as reliable as traditional machines, as they are prone to breakdowns and malfunctions due to their complex nature.

What are the disadvantages of milling machine?

Milling machines can be very expensive, especially when compared to other types of machining tools. They also require a large amount of space in a workshop, as they are typically much larger than other types of machining tools. Additionally, milling machines require a significant amount of setup time before they can be used, which can be costly in terms of both time and money. Furthermore, milling machines are not as precise as other types of machining tools, and they can be difficult to use for certain types of materials. Finally, milling machines can be quite noisy, which can be a nuisance in a workshop environment.

What is CNC?

CNC stands for Computer Numerical Control, and it is a type of automation technology used in the manufacturing industry. It is a process in which a computer is used to control the movement of a machine tool, such as a lathe, milling machine, router, or grinder. The computer is programmed with a set of instructions that tell the machine tool how to move and what operations to perform. CNC machines are used to produce a wide variety of products, from simple parts to complex components.

CNC machines are highly accurate and can produce parts with very tight tolerances. They are also very efficient, as they can produce parts quickly and with minimal waste. CNC machines are also very versatile, as they can be programmed to perform a variety of operations, such as drilling, milling, turning, and grinding.

CNC machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products. They are also used in the production of furniture, musical instruments, and toys.