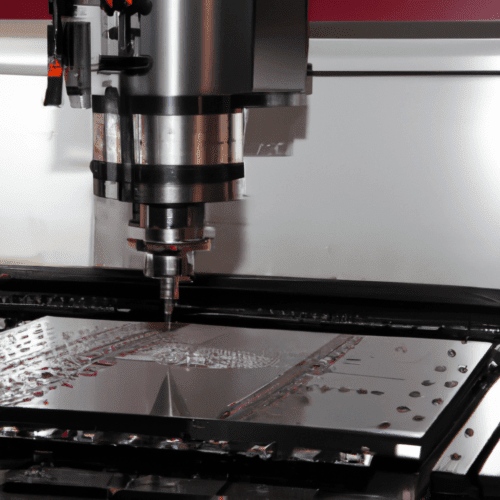

Computer Numerical Control (CNC) machines are automated machines that are used to perform a variety of tasks with precision and accuracy. CNC machines are used in a wide range of industries, including aerospace, automotive, medical, and consumer products. CNC machines are used to produce parts for a variety of products, including aircraft, automobiles, medical devices, and consumer products.

CNC machines are used to produce parts with high precision and accuracy. They are used to produce parts with complex shapes and intricate details. CNC machines are also used to produce parts with tight tolerances and high repeatability. CNC machines are used to produce parts with a high degree of accuracy and repeatability, which is essential for many industries.

CNC machines are also used to produce parts with a high degree of complexity. CNC machines are used to produce parts with complex shapes and intricate details. CNC machines are also used to produce parts with tight tolerances and high repeatability. CNC machines are used to produce parts with a high degree of accuracy and repeatability, which is essential for many industries.

CNC machines are also used to produce parts with a high degree of automation. CNC machines are used to produce parts with a high degree of automation, which reduces the need for manual labor and increases productivity. CNC machines are used to produce parts with a high degree of automation, which reduces the need for manual labor and increases productivity.

CNC machines are also used to produce parts with a high degree of flexibility. CNC machines are used to produce parts with a high degree of flexibility, which allows for the production of parts with different shapes and sizes. CNC machines are used to produce parts with a high degree of flexibility, which allows for the production of parts with different shapes and sizes.

CNC machines are also used to produce parts with a high degree of precision. CNC machines are used to produce parts with a high degree of precision, which is essential for many industries. CNC machines are used to produce parts with a high degree of precision, which is essential for many industries.

What are the applications where CNC is most suitable?

Computer Numerical Control (CNC) is a technology that uses computers to control machine tools such as lathes, mills, routers, and grinders. It is used to automate the production of parts and components in a variety of industries, including automotive, aerospace, medical, and consumer products. CNC is most suitable for applications that require high precision and repeatability, such as machining complex shapes, drilling holes, and cutting threads.

CNC is also used in the production of molds and dies, which are used to create parts and components with complex geometries. CNC is also used in the production of precision parts, such as gears, bearings, and other components used in the automotive and aerospace industries. CNC is also used in the production of medical implants and prosthetics, as well as in the production of consumer products such as toys and electronics.

CNC is also used in the production of printed circuit boards (PCBs), which are used in the electronics industry. CNC is used to create the intricate patterns and shapes required for the production of PCBs.

What is the function of CNC?

CNC, or Computer Numerical Control, is a type of automation technology used in the manufacturing industry. It is a system that uses computer-controlled machines to automate the production process. CNC machines are programmed with instructions that tell them how to move and shape materials, such as metal, plastic, and wood. The instructions are written in a computer language called G-code, which is a set of commands that tell the machine what to do. CNC machines are used to create parts and components for a variety of industries, including automotive, aerospace, medical, and consumer products.

CNC machines are used to create parts with a high degree of accuracy and repeatability. They can be programmed to produce parts with complex shapes and intricate details. CNC machines are also used to create parts with a high degree of precision, which is important for many industries. CNC machines are also used to create parts with a high degree of repeatability, which is important for mass production.

What are the advantages of CNC machine?

CNC (Computer Numerical Control) machines are automated machines that are used to perform a variety of tasks in manufacturing and other industries. CNC machines are highly accurate and can be programmed to perform complex tasks with precision and repeatability. The advantages of CNC machines include increased productivity, improved accuracy, reduced labor costs, improved safety, and increased flexibility.

Increased productivity is one of the main advantages of CNC machines. CNC machines can be programmed to perform multiple tasks in a single cycle, which can significantly reduce the amount of time it takes to complete a job. This can result in increased production rates and improved efficiency.

Improved accuracy is another advantage of CNC machines. CNC machines are programmed to perform tasks with a high degree of accuracy and repeatability. This can help to reduce errors and improve the quality of the finished product.

Reduced labor costs is another advantage of CNC machines. CNC machines can be programmed to perform complex tasks with minimal human intervention.

What is the principle of CNC machine?

The principle of CNC (Computer Numerical Control) machines is to use a computer to control the movement of a machine tool. This is done by inputting a set of instructions into the computer, which then controls the movement of the machine tool. The instructions are usually written in a programming language such as G-code, which is a language specifically designed for CNC machines. The instructions tell the machine tool what to do, such as how fast to move, what direction to move in, and how much material to remove.

CNC machines are used in a variety of industries, such as automotive, aerospace, and medical. They are used to create parts with high precision and accuracy, and can be used to create complex shapes and designs. CNC machines are also used to create molds and dies for injection molding and die casting.

The main advantage of CNC machines is that they are highly accurate and repeatable. This means that the same part can be produced multiple times with the same level of accuracy.

Why are CNC machines used in manufacturing industries?

CNC (Computer Numerical Control) machines are used in manufacturing industries because they offer a number of advantages over traditional manual machining. CNC machines are highly accurate, repeatable, and reliable, allowing for precise and consistent production of parts. They are also able to produce complex shapes and intricate details that would be difficult or impossible to achieve with manual machining. Additionally, CNC machines are able to operate at a much faster rate than manual machining, allowing for increased production and reduced labor costs.

CNC machines are also able to be programmed to produce multiple parts with minimal setup time, allowing for quick and efficient production of multiple parts. This is especially useful for industries that require large quantities of identical parts. Additionally, CNC machines are able to be programmed to produce parts with a variety of materials, allowing for increased flexibility in production.

Overall, CNC machines offer a number of advantages over manual machining, making them an invaluable tool for many manufacturing industries. They are highly accurate, repeatable, and reliable, allowing for precise and consistent production of parts.

How many operations does a CNC machine have?

A CNC (Computer Numerical Control) machine is a type of automated machine tool that uses computer programs to control the movement of the machine’s tools. CNC machines are used to produce parts with high precision and accuracy. The number of operations a CNC machine can perform depends on the type of machine and the complexity of the parts being produced. Generally, CNC machines can perform a variety of operations, including drilling, milling, turning, and grinding.

Drilling is a common operation performed by CNC machines. This operation involves using a drill bit to create a hole in a workpiece. The drill bit is held in a spindle and is moved in a linear direction to create the hole. The depth and diameter of the hole can be controlled by the CNC machine’s program.

Milling is another operation that can be performed by a CNC machine. This operation involves using a rotating cutting tool to remove material from a workpiece. The cutting tool is held in a spindle and is moved in a linear direction to create the desired shape.

What is the function of CNC?

CNC, or Computer Numerical Control, is a type of automation technology used in the manufacturing industry. It is a system that uses computer-controlled machines to automate the production process. CNC machines are programmed with instructions that tell them how to move and shape materials, such as metal, plastic, and wood. The instructions are written in a computer language called G-code, which is a set of commands that tell the machine what to do.

CNC machines are used to produce a wide variety of products, from car parts to medical devices. They are used in many industries, including aerospace, automotive, medical, and consumer products. CNC machines are highly accurate and can produce complex shapes and designs with precision. They are also able to produce parts with a high degree of repeatability, meaning that the same part can be produced multiple times with the same results.