Preparing to write a CNC program is a critical step in ensuring its success and efficiency. Rushing into programming without proper planning can lead to errors, inefficiency, and wasted time. By following these six key steps before writing a CNC program, you can avoid common pitfalls and create a program that meets your machining requirements effectively.

Step 1: Determine the machining operations to be performed

Before starting the program, it is crucial to identify the specific machining operations required for the workpiece. Simple workpieces may have straightforward operations, but as complexity increases, it becomes essential to isolate and plan every necessary operation. One effective method is to mark up a working copy of the engineering drawing with colored pens to visualize the machined surfaces.

Step 2: Decide the machining order

Establishing the correct sequencing of machining operations is vital for efficient programming. As a general rule, roughing should be completed before finishing. Using a sequence of operations planning form helps maintain order and ensures no steps are overlooked.

Step 3: Do the math

Performing mathematical calculations before programming saves time and minimizes interruptions. This includes calculating coordinates and determining speeds and feeds needed for the program. By completing these calculations in advance, you can focus on the programming without constant interruptions.

Step 4: Consider the workholding device

Understanding the workholding device and how the workpiece will be held is critical for creating a successful CNC program. Factors such as fixture orientation, clamps, and jaw configuration for three-jaw chucks should be taken into account. Preparing for the workholding device ensures that the program considers all necessary aspects.

Step 5: Consider the cutting tools

The choice of cutting tools directly affects the cutting conditions and overall program performance. Consider the type of cutting tools, their components, and any special considerations such as rigidity or clearance issues. Choosing the right cutting tools guarantees optimal results.

Step 6: Write the documentation

Developing setup and production run documentation in advance helps clarify the steps and requirements of the CNC program. This documentation assists operators and setup personnel in performing their tasks effectively. It also serves as a reference for future use and troubleshooting.

Proper preparation is essential for successful CNC program writing. Neglecting these key steps can lead to errors, inefficiency, and difficulties in program verification. Taking the time to plan and prepare ensures precision, efficiency, and minimizes downtime caused by incorrect programs.

Step 1: Determine the machining operations to be performed

Before creating a CNC program, it is essential to determine the specific machining operations that need to be performed on the workpieces. While simple workpieces may require straightforward operations, more complex workpieces require careful consideration and isolation of all necessary machining processes.

One effective method for identifying machined surfaces is to utilize colored pens and mark up a working copy of the engineering drawing. This visual aid helps visualize the areas that need to be machined and ensures that no critical operations are overlooked during the programming stage.

To determine the machining operations required, meticulously examine the workpiece design, inspect the tolerances and surface finish requirements, and consider any special features or complex geometries. By thoroughly understanding the workpiece’s machining requirements, you can proceed with confidence to plan the subsequent steps in the CNC program development process.

Visualizing workpiece and identifying machining operations using colored pens

Step 2: Decide the Machining Order

The order in which machining operations are conducted plays a crucial role in the success and efficiency of a CNC program. By carefully determining the machining order, manufacturers can optimize their workflow and ensure a smooth production process.

A general rule of thumb is to rough out all the operations before moving on to the finishing stages. This allows for faster material removal and reduces the risk of damaging delicate finishing surfaces. It is important to plan and consider the specific requirements of each machining operation to avoid any unnecessary repetition or errors.

To aid in organizing the machining order, a sequence of operations planning form can be utilized. This form helps keep track of the various operations and ensures that nothing is overlooked or forgotten. It provides a visual representation of the order in which the operations will be executed, helping operators and programmers to stay on track throughout the process.

Here is an example of a sequence of operations planning form:

| Machining Operation | Order |

|---|---|

| Facing | 1 |

| Drilling | 2 |

| Milling | 3 |

| Turning | 4 |

This planning form allows for a clear visualization of the machining order, ensuring that every operation is accounted for and carried out in the proper sequence.

By considering the machining order and utilizing a planning form, manufacturers can enhance the efficiency and accuracy of their CNC programs, leading to improved productivity and reduced errors.

Step 3: Do the math

Performing mathematical operations before programming is a crucial step in CNC program preparation. It helps avoid interruptions and maintains focus throughout the programming process. By calculating coordinates, speeds, and feeds required for the program, CNC operators can ensure precise and efficient machining operations.

Mathematical operations play a vital role in determining the movement of the tool and workpiece, as well as optimizing cutting conditions. Calculating precise coordinates allows for accurate positioning of the tool, ensuring it follows the desired cutting path. This enhances the quality and consistency of the machined parts.

When it comes to speed and feed calculations, various factors need to be considered. These include the type of material being machined, the cutting tool’s specifications, and the desired surface finish. By determining the appropriate speeds and feeds, operators can maximize productivity while minimizing tool wear and material damage.

Coordinate Calculation

Coordinate calculation involves determining the X, Y, and Z positions of the tool and workpiece in relation to the CNC machine’s reference point. This is typically based on the part’s design and the desired machining operations.

Using formulas and geometric principles, operators can accurately calculate the coordinates for each tool movement. This ensures precise machining and avoids any potential collisions or inaccuracies.

Speeds and Feeds Calculation

Speed and feed calculations are necessary for optimizing the cutting conditions during machining. In CNC programming, speeds refer to the rate at which the tool moves, while feeds represent the speed at which the tool engages with the material.

Factors such as the material’s hardness, the cutting tool’s specifications, and the desired surface finish influence the selection of appropriate speeds and feeds. By calculating these parameters, operators can achieve efficient material removal rates without compromising the tool’s lifespan.

It’s important to note that manufacturers often provide recommended speeds and feeds for their cutting tools. These recommendations are based on extensive testing and experience and should be followed for optimal results. However, operators may need to adjust these values depending on the specific machining requirements and conditions.

Performing accurate mathematical calculations for coordinates, speeds, and feeds is essential for successful CNC program execution. By investing time and effort into this crucial step, operators can ensure precise and efficient machining operations, ultimately leading to high-quality parts and improved productivity.

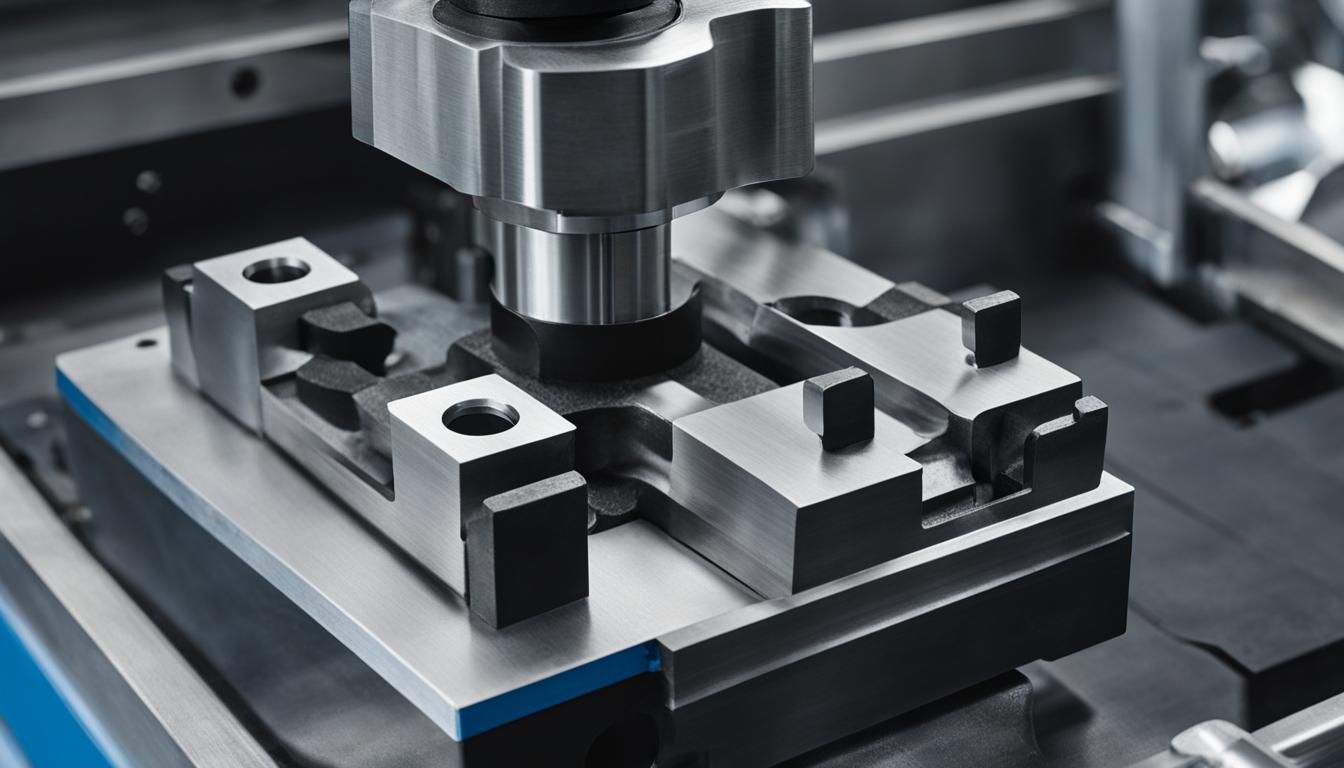

Step 4: Consider the workholding device

In order to create an acceptable CNC program, it is vital to have a thorough understanding of the workholding device and how the workpiece will be held. Proper consideration of the workholding device ensures that the workpiece remains securely in place during machining operations, preventing errors and inaccuracies.

When determining the setup for the workholding device, several factors need to be taken into account. One important consideration is the fixture orientation, which determines the positioning of the workpiece in relation to the cutting tool. By carefully choosing the fixture orientation, you can optimize the machining process and achieve the desired results.

Additionally, it is crucial to consider the clamps or other fastening mechanisms to be avoided. These may interfere with the CNC program or create obstructions during the machining process. By identifying and avoiding such clamps, you can ensure smooth and uninterrupted machining operations.

Another factor to consider is the jaw configuration for three-jaw chucks. The number and arrangement of jaws can affect the stability and precision of the workpiece. Selecting the appropriate jaw configuration based on the specific requirements of the workpiece enhances the accuracy and quality of the machining process.

By carefully considering the workholding device, fixture orientation, clamps to be avoided, and jaw configuration for three-jaw chucks, you can create a CNC program that is optimized for efficiency and accuracy. Taking the time to plan the setup and workholding device ensures that the workpiece remains securely in place and allows for seamless machining operations.

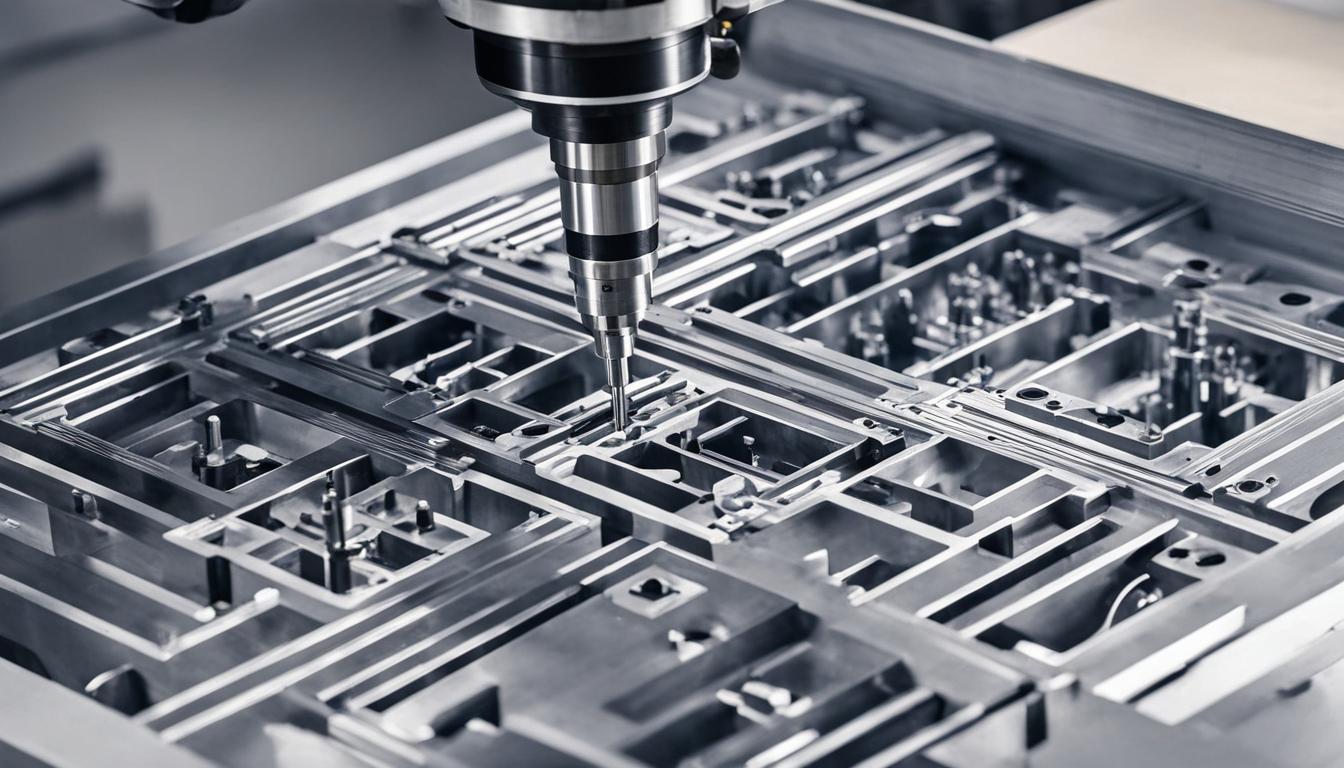

Step 5: Consider the cutting tools

When it comes to CNC programming, the choice of cutting tools plays a crucial role in determining the cutting conditions for a successful machining operation. Factors such as rigidity, clearance, and the overall condition of the tools directly impact the quality and efficiency of the program.

Considering the type of cutting tool and its components is essential. Different tools are designed for specific purposes, whether it’s drilling, turning, or milling. Each tool has unique features that determine its effectiveness in various cutting conditions.

One important aspect to consider is the rigidity of the cutting tools. Rigidity refers to the tool’s ability to resist bending or flexing during the cutting process. A rigid tool ensures accurate and precise cuts, reducing the risk of dimensional errors.

Clearance is another critical consideration. It determines the space required for chip evacuation during the cutting process. Sufficient clearance ensures that the chips don’t interfere with the cutting action, preventing tool damage and ensuring smooth machining.

To provide a comprehensive overview, let’s take a look at the different types of cutting tools:

- Drills: Used for creating holes of various sizes and depths.

- End mills: Ideal for creating precise and intricate shapes in materials.

- Turning tools: Used for cylindrical parts and provide excellent surface finish.

Here is an example of the various cutting tools and their components:

| Cutting Tool | Components |

|---|---|

| Drill | Point angle, flutes, shank, and diameter |

| End mill | Cutting edge, flute, shank, and diameter |

| Turning tool | Insert, tool holder, rake angle, and clearance angle |

These examples demonstrate the need to consider cutting conditions, rigidity, clearance, and the specific requirements of each cutting tool when developing a CNC program. By selecting the right tools and optimizing the cutting conditions, you can achieve precise and efficient machining results.

Step 6: Write the Documentation

As the final step in preparing a CNC program, it is crucial to develop comprehensive documentation that outlines the setup and production run process. Documentation plays a vital role in clarifying the steps and requirements of the CNC program, ensuring smooth operations and minimizing errors during setup and production.

The setup documentation provides detailed guidance for the personnel responsible for setting up the machine and workpiece. It includes information on fixture orientation, clamping methods, tooling specifications, and any other setup considerations. By documenting these essential details in advance, operators can efficiently and accurately configure the CNC machine for the production run.

Additionally, production run documentation outlines the specific steps and parameters required to execute the CNC program successfully. This documentation serves as a guide for machine operators, detailing the sequence of operations to be performed, tool changes, feed rates, cutting speeds, and any other relevant information.

By documenting the setup and production run processes, operators and setup personnel can refer back to these instructions, ensuring consistency and minimizing the risk of human error. This documentation also facilitates knowledge transfer within the organization, enabling other team members to understand and replicate successful setups and production runs.

To illustrate the importance of clear and concise documentation, here is a sample table that represents a section of a setup document:

| Step | Description |

|---|---|

| 1 | Mount the workpiece on the milling machine vise |

| 2 | Set the workpiece orientation to XYZ coordinates: 0, 0, 0 |

| 3 | Secure the workpiece using four clamps |

| 4 | Insert an end mill cutter with a diameter of 0.5 inches into the spindle |

| 5 | Apply cutting fluid for better heat dissipation |

In this example, the table provides clear instructions for each step of the setup process, ensuring consistency and minimizing setup errors.

By investing time and effort into writing thorough documentation, you can streamline the setup and production run process, improve communication within your team, and enhance the overall efficiency of your CNC program.

Importance of Proper CNC Program Preparation

Skipping or neglecting the proper preparation steps for a CNC program can lead to errors, inefficiency, and difficulties in verification. Taking the time to prepare ensures precision, efficiency, and minimizes downtime caused by incorrect programs.

Proper CNC program preparation is crucial for achieving optimal results in machining operations. By following a systematic approach and considering various factors, programmers can reduce the risk of errors and improve overall efficiency.

Benefits of CNC Program Preparation:

- 1. Improved Accuracy: Thorough preparation allows programmers to anticipate potential errors and address them before the program is executed. This helps in achieving accurate machining results.

- 2. Enhanced Efficiency: By carefully planning the sequence of operations and optimizing cutting conditions, programmers can minimize unnecessary tool movements and reduce machining time.

- 3. Minimized Downtime: Properly prepared CNC programs reduce the chances of errors and collisions, minimizing machine downtime and avoiding costly repairs.

- 4. Streamlined Verification: A well-prepared program makes it easier to verify the correctness of the program before execution. This helps in identifying and rectifying any issues early on, saving time and resources.

- 5. Optimal Tool Life: Consideration of factors like workholding devices, cutting tools, and feeds and speeds during program preparation ensures the longevity of cutting tools, reducing tool wear and replacement costs.

By investing time and effort in CNC program preparation, programmers can enhance the overall efficiency of machining operations and maximize productivity.

Key Concepts in CNC Programming

When delving into the world of CNC programming, understanding key concepts and fundamentals is essential for creating successful programs and ensuring smooth operation. Here, we discuss some of the core concepts that form the foundation of CNC programming.

Computer Numerical Control (CNC)

At the heart of CNC programming lies the concept of Computer Numerical Control. CNC is a technology that utilizes computer software and electronic systems to control machines, providing precise and automated control over various machining operations. CNC programming allows users to create instructions that guide the machine in executing specific tasks with the utmost accuracy.

Reference Position Commands

Reference position commands play a crucial role in CNC programming. These commands specify the starting point or reference position of the machine and define the coordinate system used for executing the program. By setting the reference position correctly, programmers can ensure accurate positioning and alignment of the machine during the machining process.

Feedrate and Speed Control

Feedrate and speed control are vital aspects of CNC programming that directly impact the efficiency and quality of machining operations. Programmers need to set appropriate feedrates and speeds to control the movement of the machine and optimize cutting conditions. Achieving the right balance between feedrates and speeds can result in improved productivity, reduced tool wear, and enhanced surface finish.

Tooling and Tool Changes

The selection and management of cutting tools are critical considerations in CNC programming. Programmers must choose the appropriate tools for the required machining operations, taking into account factors such as material, cutting conditions, and tool life. Efficient tool change strategies need to be implemented to minimize downtime and maximize productivity.

Interpolation

Interpolation refers to the ability of CNC machines to move along multiple axes simultaneously, enabling the creation of complex shapes and contours. CNC programmers must understand and utilize interpolation techniques effectively to achieve precise and efficient machining results.

By grasping these key concepts in CNC programming, programmers can develop programs that optimize efficiency, accuracy, and productivity. Now let’s explore the importance of speeds and feeds in CNC machining, ensuring optimal tool performance and quality results.

Importance of Speeds and Feeds in CNC Machining

When it comes to CNC machining, using the correct speeds and feeds is crucial for achieving optimal results and extending the tool life of milling cutters. Speeds refer to the rate at which the cutting tool moves, while feeds determine the depth and speed of the cut. Balancing these factors is essential for achieving efficient and accurate machining operations.

By following the manufacturer’s recommendations and utilizing formulas and guidelines, operators can optimize speeds and feeds for different materials, cutter types, and machining operations. This helps in reducing tool wear, improving surface finish, and increasing overall productivity.

It’s important to consider the following factors when determining speeds and feeds:

- Material properties: Different materials require varying cutting speeds and feeds to achieve optimal results. Factors such as hardness, heat resistance, and machinability should be taken into account.

- Cutter geometry: The design and structure of the milling cutter impact its cutting capabilities. Factors such as tool diameter, number of flutes, and rake angle influence the speeds and feeds that should be used.

- Workpiece stability: The stability of the workpiece during machining affects the cutting forces experienced by the tool. Proper fixturing and workholding techniques play a vital role in determining suitable speeds and feeds.

- Tool life considerations: Higher cutting speeds may result in increased tool wear, while lower speeds can reduce tool life. Finding the right balance between productivity and tool longevity is crucial.

- Machine capabilities: The capabilities of the CNC machine, including its spindle speed range and feed rate capabilities, should be taken into account when determining speeds and feeds.

Optimizing Speeds and Feeds for CNC Machining

To optimize speeds and feeds, it’s recommended to consult the cutting tool manufacturer’s catalog or website, which typically provides recommendations for various materials and cutter types. Additionally, many CNC software programs and online calculators are available to help calculate speeds and feeds based on specific parameters.

The image above shows a selection of milling cutters commonly used in CNC machining.

By carefully considering speeds and feeds, operators can achieve efficient material removal, reduce tool wear, and ultimately improve the overall quality and productivity of CNC machining operations.

| Material | Cutting Speed (SFM) | Feed Rate (IPM) |

|---|---|---|

| Aluminum | 1000-3000 | 0.005-0.020 |

| Steel | 200-1000 | 0.001-0.010 |

| Stainless Steel | 150-700 | 0.001-0.005 |

Best Practices for CNC Program Writing and Structure

Writing and structuring CNC programs require attention to detail and adherence to best practices. By following these guidelines, you can improve program management, readability, and reusability, ultimately optimizing your CNC machining processes.

1. Properly naming files

Effective file naming is crucial for organizing and locating CNC programs efficiently. Use descriptive names that clearly identify the program’s purpose, related part or project, and version number. Avoid generic names or placeholders that may lead to confusion or difficulty in finding specific programs.

2. Listing machining phases and tools

Creating a comprehensive list of machining phases and tools used in the CNC program enhances clarity and understanding. Clearly define each phase and the corresponding tools required, including information such as tool type, diameter, and cutting speeds. This helps operators and setup personnel follow the program accurately and facilitates troubleshooting and optimization.

3. Utilizing subroutines

Subroutines are reusable sections of code that simplify CNC program writing and structure. By breaking down complex operations into smaller, modular routines, you can improve program readability, eliminate redundant code, and facilitate program modifications. Subroutines also promote consistency and standardization across multiple programs.

4. Including comments for clarity

Adding comments within the CNC program provides valuable insights and clarifications for future reference. Comments can explain the purpose of specific code segments, highlight important considerations, or provide additional instructions for setup or operation. Well-placed comments improve program comprehension and aid in troubleshooting and maintenance.

5. Ensuring consistency and adherence to standards

Maintaining consistency in CNC program writing and structure is essential for ease of use and efficient program management. Adhere to established industry standards and company-specific guidelines, including formatting conventions, programming syntax, and code organization. Consistency across programs simplifies training, reduces errors, and enables better collaboration.

6. Documenting changes and revisions

Keeping a record of changes and revisions made to CNC programs is crucial for traceability and version control. Maintain a comprehensive document or log that details modifications, including the reasons behind the changes and any associated performance improvements or troubleshooting notes. This documentation ensures transparency and aids in maintaining program integrity.

By implementing these best practices for CNC program writing and structure, you can optimize your machining processes, increase productivity, and achieve consistent and reliable results.

Leveraging Technology for CNC Program Management

In today’s digital age, the management of CNC programs has been greatly improved through the utilization of technology. With the advent of Industry 4.0 and the capabilities provided by modern CNC machines, manufacturers have the opportunity to enhance their program management, production monitoring, and coordination processes.

One key aspect of this technological advancement is the integration of network connectivity into CNC machines. This allows for seamless communication between the machines and other system components, enabling real-time data exchange and remote monitoring. By leveraging network connectivity, manufacturers can monitor the status of CNC programs, track production progress, and make timely adjustments to optimize efficiency.

Another important tool for effective CNC program management is file management software. This software allows manufacturers to organize, store, and retrieve CNC program files efficiently. With robust file management capabilities, manufacturers can easily search for specific programs, ensure version control, and securely share files across different machines or with external partners. This not only streamlines the program management process but also reduces the risk of errors caused by outdated or incorrect program versions.

By embracing these technological advancements in CNC program management, manufacturers can align themselves with the principles of Industry 4.0. This holistic approach emphasizes the integration and automation of manufacturing processes, as well as the utilization of data analytics and artificial intelligence to drive efficiency and productivity. Through the effective use of network connectivity and file management software, manufacturers can optimize CNC program management, improve production coordination, and stay competitive in the rapidly evolving manufacturing landscape.