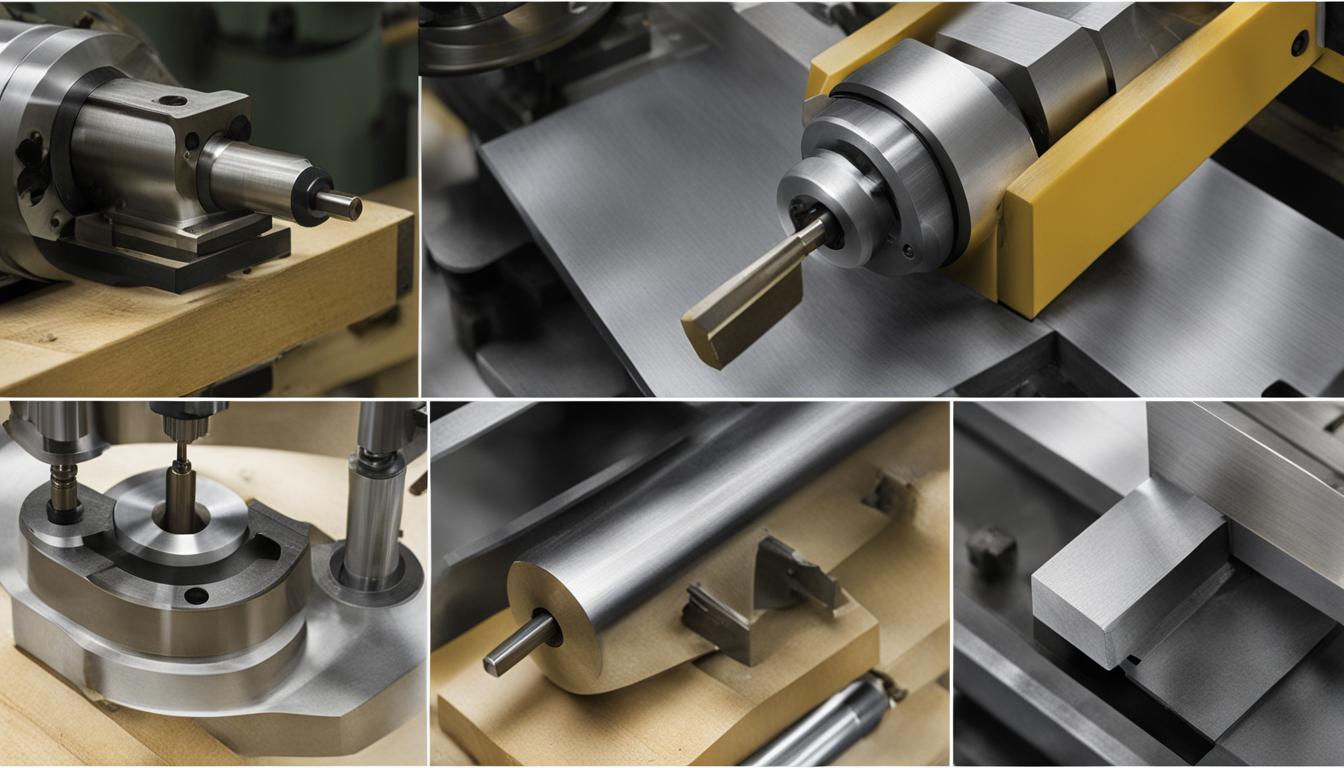

The three basic types of milling machines widely used in modern manufacturing are vertical milling machines, horizontal milling machines, and universal milling machines. Vertical milling machines feature a spindle axis oriented vertically, making them ideal for end milling, drilling, and plunge cutting operations. Horizontal milling machines have a spindle mounted parallel to the worktable, excelling at heavy-duty cutting and slotting tasks.

Universal milling machines combine features of both vertical and horizontal machines, offering a swiveling head that can be adjusted to various angles, providing exceptional versatility for a wide range of milling operations. Each type has its unique strengths and applications, catering to different manufacturing needs and project requirements. The choice between these milling machine types depends on factors such as the specific machining tasks, workpiece size, material properties, and production volume.

- The three basic types of milling machines are knee and column, horizontal, vertical, and universal milling machines.

- Knee and column milling machines are ideal for vertical milling operations and offer excellent accuracy and surface finishing.

- Horizontal milling machines can perform milling operations in vertical, cross, or horizontal directions and are known for their high spindle speeds and efficient chip evacuation.

- Vertical milling machines are suitable for tasks like slotting, machining grooves, and creating flat surfaces and allow for adjustment of the spindle for up and down movement.

- Universal milling machines are versatile and can adapt to a wide range of operations, allowing for helical milling operations and the use of additional attachments.

Knee and Column Milling Machine

The knee and column milling machine is one of the most commonly used types of milling machines. It is known for its versatility and precision in vertical milling operations. This machine consists of a vertical column attached to a bed, which supports the workpiece and rotates the knee and saddle. The knee provides vertical movement to the workpiece, while the saddle can move in a transverse direction. The combination of these movements allows for precise and accurate machining.

The knee and column milling machine is equipped with a saddle that can be adjusted to accommodate different workpieces. This makes it highly adaptable for various milling tasks. Additionally, the machine has a vertical spindle that holds the cutting tool, enabling it to efficiently cut materials with high accuracy. The vertical spindle also allows for the creation of angular surfaces and complex shapes.

The saddle of the knee and column milling machine plays a crucial role in its functionality. It provides stability and support to the workpiece during the milling process. The saddle can be moved across the table in a transverse direction, allowing for precise machining and the creation of smooth and uniform surfaces. The machine’s transverse movement capability makes it suitable for tasks that require accurate and consistent milling operations.

| Advantages | Disadvantages |

|---|---|

| Excellent accuracy | Limited flexibility in terms of workpiece size |

| High surface finishing quality | Requires frequent adjustments for different workpieces |

| Ability to create angular surfaces | Vertical movement may be limited for certain tasks |

Applications:

- Vertical milling operations

- Machining of angular surfaces

- Precision cutting and shaping

- Creation of complex shapes

Horizontal Milling Machine

In the world of milling machines, the horizontal milling machine is a key player. Also known as a plain milling machine, it offers a range of functionalities that make it highly versatile in various industries. The horizontal milling machine features a horizontal spindle, which allows for milling operations in different feed directions.

The feed directions of the horizontal milling machine include vertical, cross, and longitudinal movements. This means that the table can be adjusted to move the workpiece in these directions, enabling precise and efficient cutting. The high spindle speeds of horizontal milling machines contribute to their ability to achieve excellent surface finishing and chip evacuation.

With its robust construction, the horizontal milling machine offers stability and durability, making it suitable for heavy-duty tasks. Its ability to perform milling operations in different directions and its efficient chip evacuation system make it a popular choice in industries where accuracy and productivity are essential.

| Advantages | Disadvantages |

|---|---|

| • Versatile in feed directions | • Requires more floor space compared to vertical milling machines |

| • High spindle speeds for efficient chip evacuation | • Limited range of angular milling operations |

| • Excellent surface finishing | • May not be suitable for certain complex milling operations |

| • Robust construction for stability and durability | • Higher initial investment compared to simpler milling machines |

Overall, the horizontal milling machine is a reliable and efficient tool for various milling operations. Its ability to perform milling operations in different feed directions and its robust construction make it a valuable asset in industries that require high precision and productivity.

Vertical Milling Machine

A vertical milling machine is a type of milling machine that has a spindle positioned vertically to the table. This allows the machine to perform various tasks such as cutting slots, creating angular surfaces, and machining grooves with precision. The spindle head is fixed to a vertical column, and the milling cutter is attached to the spindle, enabling the machine to perform vertical movements for accurate shaping and cutting of materials.

The main advantage of a vertical milling machine is its versatility in handling different milling operations. It is particularly effective in creating angular surfaces due to its vertical spindle orientation. With its ability to perform precise up and down movements, this type of milling machine is also well-suited for cutting slots and machining grooves. Whether it’s a small-scale project or a large-scale industrial application, vertical milling machines offer the flexibility and precision required for a wide range of tasks.

Applications of Vertical Milling Machines:

- Slotting

- Machining grooves

- Machining angular surfaces

- Creating flat surfaces

Whether it’s for metalworking, woodworking, or other materials, vertical milling machines provide the accuracy and control needed for producing high-quality results. With their spindle configuration and vertical movement capabilities, these machines are essential tools in various industries that rely on precise shaping, cutting, and machining operations.

| Advantages of Vertical Milling Machines | Disadvantages of Vertical Milling Machines |

|---|---|

| 1. Versatile in handling different milling operations | 1. Limited horizontal movement |

| 2. Ideal for cutting slots and machining grooves | 2. May require additional fixtures for complex tasks |

| 3. Precise up and down movements for accurate shaping | 3. Limited range of workpiece size due to vertical orientation |

| 4. Suitable for creating angular surfaces | 4. May require frequent tool changes for different operations |

Universal Milling Machine

The universal milling machine is a versatile tool that offers a wide range of capabilities for various machining tasks. It is known for its ability to pivot the table at different angles, allowing for helical milling operations. This flexibility enables the machine to create complex shapes and contours with precision and accuracy.

Table Pivot

One of the key features of the universal milling machine is its pivoting table. This table can be adjusted to different angles, enabling the machine to perform helical milling operations. By pivoting the table, the machine can produce spiral grooves, threads, and other intricate patterns. This capability makes the universal milling machine suitable for tasks that require a high level of precision and attention to detail.

Attachments

In addition to its table pivot feature, the universal milling machine can also accommodate various attachments. These attachments further extend the machine’s capabilities and allow for even more diverse machining operations. Some common attachments include slotting attachments, rotary attachments, vertical milling attachments, and index heads. These attachments enable the machine to perform a wide range of tasks and produce different types of cutters.

The universal milling machine is widely used in industries such as automotive, aerospace, and manufacturing. Its versatility, precision, and ability to perform helical milling operations make it an essential tool for many machining operations. Whether it’s creating intricate shapes or producing complex parts, the universal milling machine delivers exceptional results.

Fixed Bed Type Milling Machine

A fixed bed type milling machine is a versatile and powerful tool used in various industries for cutting and shaping materials with precision. This type of milling machine is known for its rigid bed, which provides stability and strength during milling operations. The rigid bed ensures that the machine can handle heavy loads and maintain accuracy throughout the milling process.

The fixed bed type milling machine allows for horizontal and vertical movement, making it suitable for a wide range of cutting operations. The spindle head can be moved in both horizontal and vertical directions, providing flexibility and allowing for precise machining. With this machine, operators have the capability to perform milling tasks that require both horizontal and vertical movement, resulting in efficient and accurate machining.

Whether it is for intricate parts or large-scale production, the fixed bed type milling machine is a reliable choice. Its rigid bed, combined with the ability to move in both horizontal and vertical directions, makes it a versatile tool that can handle a wide range of milling operations with precision and efficiency.

Advantages of Fixed Bed Type Milling Machine:

- Stability and strength due to rigid bed construction

- Horizontal and vertical movement for versatile machining

- Accurate and precise cutting operations

- Ability to handle heavy loads

- Suitable for intricate parts and large-scale production

| Type | Advantages |

|---|---|

| Fixed Bed Type Milling Machine |

|

Simplex, Duplex, and Triplex Milling Machines

Simplex, duplex, and triplex milling machines are specialized variations that offer increased flexibility and capabilities in milling operations. These machines are designed to provide movement in multiple directions, allowing for precise and efficient machining of complex workpieces.

Simplex Milling Machines

Simplex milling machines are primarily characterized by their ability to move the spindle in one direction, usually vertically. This vertical movement enables the cutting tool to remove material from the workpiece with accuracy and precision. Simplex milling machines are commonly used for tasks that require vertical milling operations, such as machining slots and creating angular surfaces.

Duplex Milling Machines

Duplex milling machines offer additional versatility compared to simplex milling machines. In addition to vertical movement, these machines can also move the spindle horizontally, allowing for machining operations in both vertical and horizontal directions. This flexibility enables the creation of more complex and intricate shapes on the workpiece. Duplex milling machines are commonly used in industries that require precise and intricate milling operations, such as aerospace and automotive manufacturing.

Triplex Milling Machines

Triplex milling machines are the most advanced and versatile among the three types. These machines feature spindles that can move in all three directions: X, Y, and Z axes. This triple-axis movement allows for intricate and precise milling operations on complex workpieces. Triplex milling machines, also known as “plano millers,” are commonly used in heavy-duty industrial applications and specialized milling operations.

| Type of Milling Machine | Movement |

|---|---|

| Simplex | Vertical |

| Duplex | Vertical and Horizontal |

| Triplex | X, Y, and Z Axes |

Rotary Table Milling Machine

A rotary table milling machine is a versatile tool used for precision milling operations. It features a circular table that can rotate vertically, allowing for multi-sided machining of workpieces. This type of machine is commonly used in industries such as automotive, aerospace, and manufacturing, where continuous workpiece loading is required.

The circular table of a rotary table milling machine provides a stable platform for mounting multiple cutters at different heights. With the ability to rotate the table, the machine can rough up and finish the workpiece from various angles, ensuring precise and efficient machining. This versatility makes it ideal for tasks that involve complex shapes, angled surfaces, or intricate detailing.

One of the key advantages of a rotary table milling machine is the ability to load and unload workpieces while the machine is in operation. This continuous workpiece loading feature significantly increases productivity and reduces downtime. Operators can seamlessly switch between different workpieces without the need to stop and restart the machine, resulting in improved efficiency and cost-effectiveness.

| Advantages | Applications | Key Features |

|---|---|---|

|

|

|

Tracer Controlled Milling Machine

Tracer controlled milling machines are highly specialized tools used in industries that require the precise replication of complex and irregular shapes. These machines utilize a servomechanism arrangement, making them capable of executing intricate milling operations with exceptional accuracy. Tracer controlled milling machines are particularly effective in the production of intricate dies and molds, where precision and attention to detail are paramount.

The operation of a tracer controlled milling machine involves the use of a stylus that energizes the oil relay system, thereby operating the hydraulic system of the table. This system allows the machine to trace and reproduce the desired shape with remarkable precision. The servomechanism arrangement ensures that the machine maintains precise control, enabling the creation of intricate and complex shapes.

The versatility of tracer controlled milling machines makes them invaluable in various industries. From the aerospace sector, where they are used to produce intricate components, to the automotive industry, where they contribute to the manufacturing of complex molds, these machines play a critical role in shaping innovative products. With their ability to accurately reproduce complex shapes, tracer controlled milling machines provide manufacturers with the flexibility to meet the demands of modern design requirements.

Servomechanism Arrangement

The servomechanism arrangement in tracer controlled milling machines allows for precise control over the movement of the milling head and table. The stylus interacts with the workpiece, transmitting signals that are then translated into hydraulic movements. This system ensures that every movement is executed with the utmost precision, resulting in the production of complex shapes with exceptional accuracy.

CNC Milling Machine

CNC milling machines revolutionized the milling industry with their computer-controlled operations. These advanced machines offer precise and efficient three-axis movement, making them highly versatile for a wide range of applications. With their ability to execute complex programs, CNC milling machines have become the go-to option for industries that require high precision and speed in their milling processes.

Computer-controlled milling machines, or CNC machines, follow instructions from a computer program to move the workpiece in the X, Y, and Z axes. This allows for intricate and precise cuts, ensuring superior accuracy and consistency. The computer-controlled nature of CNC milling machines eliminates the need for manual intervention, reducing the chances of errors and increasing productivity.

The versatility of CNC milling machines is one of their greatest strengths. These machines can be used to create a wide variety of parts and components with different shapes, sizes, and complexities. From simple flat surfaces to complex 3D shapes, CNC milling machines can handle it all. This versatility makes them invaluable in industries such as automotive, aerospace, and manufacturing, where precision and efficiency are paramount.

| Advantages of CNC Milling Machines | Applications |

|---|---|

| High precision and accuracy | Automotive industry |

| Efficient and fast milling operations | Aerospace industry |

| Ability to create complex shapes | Manufacturing industry |

| Reduced manual intervention | Tool and die making |

| Increased productivity | Prototype development |

In conclusion, CNC milling machines have transformed the milling industry by combining computer-controlled operations, three-axis movement, and versatility. These machines offer superior precision, speed, and efficiency in a wide range of applications. With their ability to create complex shapes and reduce manual intervention, CNC milling machines have become an indispensable tool for industries that demand high-quality machining processes.

Drum Milling Machine

A drum milling machine is a versatile tool used in various industries for continuous milling operations. It features a rotary table that rotates horizontally, providing precise and efficient machining of workpieces. The horizontal rotation of the drum allows for consistent and uniform cutting, resulting in high-quality finished parts.

One of the key components of a drum milling machine is the spindle heads. These spindle heads, typically three or four in number, are responsible for removing the metal from the workpiece. With each rotation of the drum, the spindle heads perform the cutting operation, ensuring a smooth and accurate milling process.

The drum milling machine is commonly used in applications where continuous milling is required, such as in the production of cylindrical components, gears, and threads. Its ability to handle large workpieces and perform multiple milling operations in one setup makes it a cost-effective solution for various manufacturing needs.

Advantages of Drum Milling Machine:

- Continuous milling operation ensures high productivity

- Precise and accurate cutting for quality finished parts

- Capability to handle large workpieces

- Efficient removal of material with spindle heads

Applications of Drum Milling Machine:

- Production of cylindrical components

- Machining gears and threads

- Manufacturing of precise and complex parts

| Advantages | Applications |

|---|---|

| Continuous milling operation ensures high productivity | Production of cylindrical components |

| Precise and accurate cutting for quality finished parts | Machining gears and threads |

| Capability to handle large workpieces | Manufacturing of precise and complex parts |

| Efficient removal of material with spindle heads |

Specialized Milling Machines

In addition to the basic types of milling machines, there are specialized milling machines that cater to specific tasks and materials. These machines have revolutionized the milling industry by enhancing the capabilities of traditional milling processes. Two prominent examples of specialized milling machines are 5-axis milling machines and planetary milling machines.

5-Axis Milling Machines

5-axis milling machines enable the production of complex shapes with greater ease and efficiency. Unlike traditional milling machines that operate in three axes (X, Y, and Z), 5-axis machines offer two additional rotational axes, allowing for multi-directional cutting and increased flexibility. This capability enables manufacturers to achieve intricate designs and precise machining in fewer setups, reducing production time and cost.

Planetary Milling Machines

Planetary milling machines incorporate a unique mechanism that sets them apart from other milling machines. Multiple cutters are arranged in a planetary manner around the workpiece, resulting in simultaneous milling from different angles. This approach ensures uniform material removal, improved surface finishing, and enhanced productivity. Planetary milling machines are particularly useful for working on large and complex components, such as turbine blades and automotive engine parts.

Specialized milling machines like 5-axis and planetary milling machines have found applications in various industries, including medical, aerospace, and automotive. They have opened up new possibilities for precision manufacturing and enabled the production of intricate components that were once challenging to create. As technology continues to advance, specialized milling machines will play a crucial role in pushing the boundaries of milling capabilities.

FAQ

What are the three basic types of milling machines?

The three basic types of milling machines are knee and column, horizontal, and vertical milling machines.

What is a knee and column milling machine?

A knee and column milling machine consists of a vertical column attached to a bed that rotates the knee and saddle. It is ideal for vertical milling operations.

What is a horizontal milling machine?

A horizontal milling machine, also known as a plain milling machine, has a horizontal spindle and can perform milling operations in vertical, cross, or horizontal directions.

What is a vertical milling machine?

A vertical milling machine has a spindle that is perpendicular or vertical to the table. It is suitable for tasks like slotting, machining grooves, and creating flat surfaces.

What is a universal milling machine?

A universal milling machine is versatile and can adapt to a wide range of operations. The table can pivot at various angles, allowing for helical milling operations.

What is a fixed bed type milling machine?

A fixed bed type milling machine has a rigid bed attached to the machine. The saddle and knee cannot be rearranged, and the spindle head is movable in horizontal and vertical directions.

What are simplex, duplex, and triplex milling machines?

Simplex milling machines have a spindle that can only travel in one direction, typically vertical. Duplex milling machines can move the spindle in both horizontal and vertical directions. Triplex milling machines have a spindle that can move in all three directions – X, Y, and Z axis.

What is a rotary table milling machine?

A rotary table milling machine consists of a circular table that rotates vertically. Multiple cutters are set at different heights to rough up and finish the workpiece.

What is a tracer controlled milling machine?

A tracer controlled milling machine is used for tracing and reproducing complex and irregular shapes. It uses a stylus to energize the oil relay system and has precise control for intricate dies and molds.

What is a CNC milling machine?

A CNC milling machine is a computer-controlled machine that can travel in all three directions – X, Y, and Z axis. It offers high precision, speed, and efficiency and is suitable for a wide range of applications.

What is a drum milling machine?

A drum milling machine has a table called a drum that rotates horizontally. It is efficient for continuous milling operations, with three or four spindle heads removing metal from the workpiece.

Are there specialized milling machines?

Yes, there are specialized milling machines such as 5-axis milling machines and planetary milling machines, which enhance traditional milling processes and are used in industries such as medical, aerospace, and automotive.