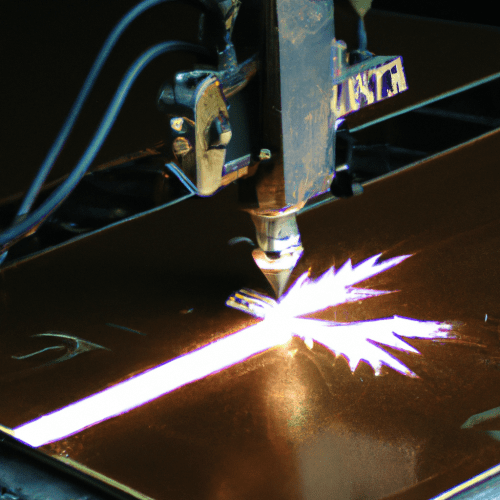

A plasma cutter is a tool used to cut through electrically conductive materials such as steel, stainless steel, aluminum, brass, and copper. It works by using an electrical arc to heat and melt the material, which is then blown away by a high-velocity stream of gas, usually compressed air. Plasma cutters are used in a variety of applications, from industrial fabrication to automotive repair and restoration.

In industrial fabrication, plasma cutters are used to cut and shape metal components for a variety of purposes. They can be used to cut large sheets of metal into smaller pieces, create intricate shapes, and cut out holes for mounting components. Plasma cutters are also used to create custom parts for industrial machinery, such as brackets, flanges, and other components.

In automotive repair and restoration, plasma cutters are used to cut out damaged sections of metal, such as rust spots or dents. They can also be used to cut out sections of metal for custom modifications, such as creating a custom exhaust system or adding a spoiler to a car.

Plasma cutters can also be used for artistic purposes, such as creating metal sculptures or decorative pieces. They can also be used to create signs and logos for businesses or organizations.

Overall, plasma cutters are a versatile tool that can be used for a variety of purposes, from industrial fabrication to automotive repair and restoration to artistic endeavors.

What can plasma cutters be used for?

Plasma cutters are a type of cutting tool that uses a high-velocity stream of ionized gas to cut through electrically conductive materials such as steel, aluminum, brass, and copper. They are commonly used in industrial settings for cutting and shaping metal, but they can also be used for a variety of other applications. Plasma cutters are capable of cutting through thick materials quickly and accurately, making them ideal for a variety of tasks.

In industrial settings, plasma cutters are used to cut and shape metal for a variety of purposes. They can be used to cut through thick steel plates, create intricate shapes, and cut out holes for pipes and other components. Plasma cutters are also used to create custom parts for machinery and equipment, as well as for welding and fabrication.

Plasma cutters can also be used for a variety of other applications. They can be used to cut through wood, plastic, and other materials, as well as for creating decorative designs. Plasma cutters are also used in the automotive industry for cutting and shaping body panels and other components.

Can you make money with a plasma cutter?

Yes, you can make money with a plasma cutter. Plasma cutters are a type of cutting tool that uses a high-velocity stream of ionized gas to cut through metal and other materials. They are used in a variety of industries, including automotive, aerospace, and construction, and can be used to create intricate shapes and designs. With the right skills and knowledge, you can use a plasma cutter to create custom pieces for sale, such as signs, sculptures, and artwork. You can also use a plasma cutter to create parts for machines and equipment, which can be sold to businesses and individuals. Additionally, you can use a plasma cutter to provide services such as cutting and welding for customers. With the right marketing and pricing strategy, you can make a good living with a plasma cutter.

Can plasma cutter be used for welding?

Yes, a plasma cutter can be used for welding. Plasma cutting is a process that uses a high-velocity stream of ionized gas to cut through electrically conductive materials such as steel, aluminum, brass, and copper. The plasma cutter works by creating an electrical arc between an electrode and the material being cut. This arc is then used to heat the material, causing it to melt and be cut away. Plasma cutting is often used in welding applications because it is a fast and efficient way to cut metal.

When using a plasma cutter for welding, the process is similar to traditional welding. The plasma cutter is used to create an arc between the electrode and the material being welded. This arc is then used to heat the material, causing it to melt and form a weld. The plasma cutter can be used to weld a variety of materials, including steel, aluminum, brass, and copper.

What is a disadvantage of plasma cutting?

A disadvantage of plasma cutting is that it is limited in the thickness of the material it can cut. Plasma cutting is most effective when cutting materials that are 1/4 inch thick or less. If the material is thicker than this, the plasma arc will not be able to penetrate the material and the cut will be incomplete. Additionally, plasma cutting produces a lot of heat, which can cause warping of the material being cut. This can be especially problematic when cutting thin materials, as the heat can cause the material to distort or melt. Furthermore, plasma cutting produces a lot of noise and sparks, which can be dangerous in certain environments. Finally, plasma cutting is more expensive than other cutting methods, such as oxy-fuel cutting.

Can you cut wood with a plasma cutter?

Yes, you can cut wood with a plasma cutter. Plasma cutters are a type of cutting tool that uses a high-velocity stream of ionized gas to cut through electrically conductive materials, such as wood. The plasma cutter works by creating an electrical arc between an electrode and the material being cut. This arc is then used to heat the material to the point where it can be cut. The plasma cutter is able to cut through wood with ease, as long as the wood is thick enough and the plasma cutter is powerful enough.

When cutting wood with a plasma cutter, it is important to use the correct settings and techniques. The cutting speed should be set to the lowest possible setting, and the amperage should be set to the highest possible setting. This will ensure that the wood is cut cleanly and without any burning or charring. It is also important to use a steady hand when cutting, as any jerky movements can cause the plasma cutter to overheat and damage the wood.

Is a plasma cutter better than a torch?

A plasma cutter is a tool that uses a high-velocity stream of ionized gas to cut through electrically conductive materials such as steel, aluminum, brass, and copper. It is often used in industrial applications such as welding, fabrication, and metalworking. A torch, on the other hand, is a tool that uses a flame to cut through materials such as steel, aluminum, brass, and copper.

When it comes to deciding which tool is better, it really depends on the job at hand. A plasma cutter is generally more efficient and precise than a torch, and it can cut through thicker materials with greater accuracy. It is also much faster than a torch, and it can be used to cut intricate shapes and patterns. On the other hand, a torch is more versatile and can be used to cut through a wider range of materials, including wood and plastic. It is also more affordable than a plasma cutter, and it is easier to use for novice welders and fabricators.

Do you need a air compressor for a plasma cutter?

A plasma cutter is a tool that uses a high-velocity stream of ionized gas to cut through metal. It is a very useful tool for metal fabrication and is often used in welding and other metalworking applications. While a plasma cutter does not require an air compressor to operate, having one can be beneficial in certain situations.

An air compressor is used to provide a steady supply of compressed air to the plasma cutter. This compressed air helps to cool the plasma arc and can also help to increase the cutting speed and accuracy of the plasma cutter. Additionally, an air compressor can be used to power other air tools that may be used in conjunction with the plasma cutter, such as an air hammer or air grinder.

When deciding whether or not to use an air compressor with a plasma cutter, it is important to consider the type of work that will be done. If the plasma cutter will be used for light-duty work, such as cutting thin sheet metal, then an air compressor may not be necessary.

How much does a plasma cutter cost?

The cost of a plasma cutter can vary greatly depending on the size, power, and features of the machine. Generally, a basic plasma cutter with a power rating of 40 amps or less will cost between $500 and $1,500. Higher-end plasma cutters with a power rating of more than 40 amps can cost anywhere from $2,000 to $10,000 or more. The cost of a plasma cutter also depends on the type of machine you purchase. Handheld plasma cutters are typically the most affordable option, while CNC plasma cutters are more expensive. Additionally, the cost of a plasma cutter can be affected by the brand, the features, and the accessories included with the machine. For example, some plasma cutters come with a built-in air compressor, while others require you to purchase a separate air compressor. Additionally, some plasma cutters come with a built-in water table, while others require you to purchase a separate water table. Finally, the cost of a plasma cutter can also be affected by the type of consumables you purchase.