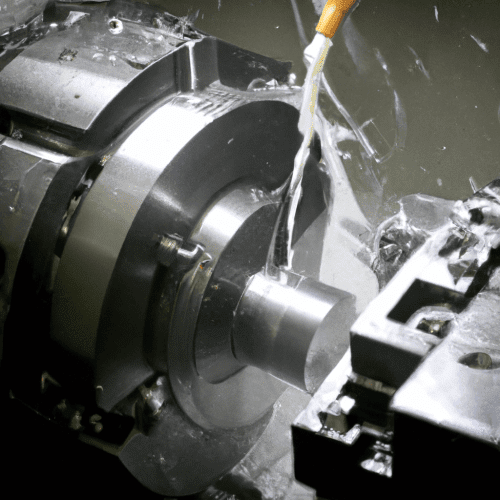

When accurate turning is needed, a lathe is typically used. A lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, parts reclamation, and much more. The cutting tool is usually fixed to a solid moveable mounting, either a toolpost or a turret, which is then moved against the rotating workpiece. The cutting tool is usually held in a tool holder which itself is mounted in the toolpost or turret. The cutting tool is usually a single-point cutting tool, but may also be a multi-point tool. The toolpost or turret is moved along the axis of rotation of the workpiece in order to cut away material to create the desired shape. The workpiece is usually held in a chuck, collet, or faceplate, which rotates with the workpiece. The accuracy of the finished workpiece is determined by the quality of the machine, the skill of the operator, and the quality of the tools used.

Which tool is used in turning process?

A turning process is a type of machining operation used to shape and finish a workpiece by removing material from the outside of the workpiece. The most common tool used in a turning process is a cutting tool, such as a lathe, which is a rotating machine tool that uses a cutting tool to shape and finish a workpiece. The cutting tool is typically a single-point cutting tool, such as a drill bit, end mill, or reamer, which is held in a tool holder and rotated at a high speed to remove material from the workpiece. Other tools used in a turning process include a boring bar, which is used to enlarge a hole, and a parting tool, which is used to cut off a piece of the workpiece. In addition, a variety of other tools, such as chamfering tools, threading tools, and knurling tools, can be used to shape and finish the workpiece.

What is the necessary for turning?

The necessary for turning is a combination of several factors. First, the driver must have a clear understanding of the rules of the road and the laws of the jurisdiction in which they are driving. This includes knowing when and where to turn, as well as the proper signals to use. Second, the driver must have the physical ability to control the vehicle, including the ability to turn the steering wheel and apply the brakes. Third, the driver must have the mental capacity to make decisions quickly and accurately in order to safely navigate the road. Finally, the driver must have the necessary visual acuity to be able to see the road and other vehicles in order to make safe turns. All of these factors must be present in order for a driver to safely and successfully turn.

Which type of tool is used in a turning center?

A turning center is a type of machine tool used for metalworking operations such as turning, drilling, boring, and threading. It is typically composed of a spindle, a tool holder, and a tailstock. The spindle is the main component of the turning center and is responsible for rotating the workpiece. The tool holder is used to hold the cutting tool, which is used to shape the workpiece. The tailstock is used to support the workpiece and can be adjusted to accommodate different sizes and shapes. The turning center can also be equipped with additional features such as a coolant system, a chip conveyor, and a CNC control system. The CNC control system allows for automated operation of the machine, allowing for greater precision and accuracy.

Can turning be done by a drill machine?

Yes, turning can be done by a drill machine. Turning is a machining process that involves the use of a cutting tool to remove material from a workpiece in order to create a desired shape or finish. A drill machine is a type of machine tool that uses a rotating cutting tool to remove material from a workpiece. The drill machine is capable of performing a variety of operations, including drilling, reaming, tapping, countersinking, and turning. Turning is one of the operations that can be performed on a drill machine. When turning on a drill machine, the cutting tool is fed into the rotating workpiece in order to remove material and create the desired shape or finish. The drill machine is capable of performing a variety of turning operations, including facing, turning, boring, and threading.

What is CNC turning used for?

CNC (Computer Numerical Control) turning is a machining process used to create parts with cylindrical features by rotating a cutting tool against a workpiece. It is a type of subtractive manufacturing, which is a process that removes material from a workpiece to create a desired shape or form. CNC turning is used to create a variety of parts, including shafts, pins, bushings, and other components used in a variety of industries, such as automotive, aerospace, medical, and electronics.

The CNC turning process begins with a workpiece, which is typically a cylindrical piece of metal, such as aluminum, steel, brass, or stainless steel. The workpiece is then mounted onto a spindle, which is connected to a CNC machine. The CNC machine is programmed with a set of instructions that tell it how to move the cutting tool and the workpiece in order to create the desired shape. The cutting tool is typically a single-point cutting tool, such as a lathe tool, drill bit, or end mill.