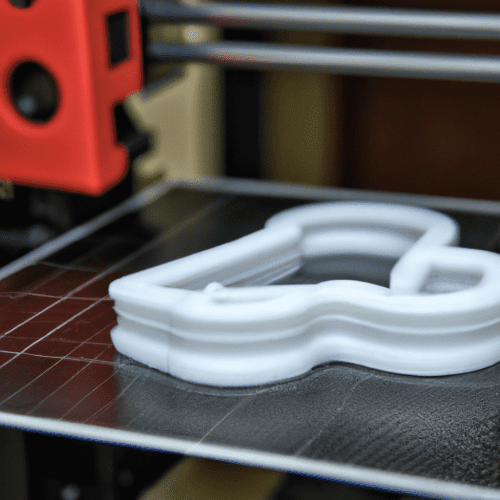

A 3D printer is a type of printer that uses additive manufacturing technology to create three-dimensional objects from a digital file. It works by laying down successive layers of material, such as plastic, metal, or ceramic, to build up the object. The printer reads the digital file and then uses a nozzle to deposit the material in the desired shape. The nozzle moves in three dimensions, allowing it to create complex shapes and objects. The printer can also be used to create prototypes, molds, and other objects. 3D printing is a relatively new technology, but it has already been used to create a wide variety of objects, from medical implants to toys. It is also being used in the automotive, aerospace, and manufacturing industries. 3D printing is revolutionizing the way products are designed and manufactured, and it is expected to have a major impact on the future of manufacturing.

What does 3D printing do?

3D printing is a process of creating three-dimensional objects from a digital file. It is also known as additive manufacturing, as it involves adding successive layers of material to create an object. 3D printing is used to create a wide variety of objects, from toys and tools to medical implants and automotive parts. The process begins with a 3D model, which is created using a computer-aided design (CAD) program. The 3D model is then sent to a 3D printer, which uses a variety of materials, such as plastic, metal, or ceramic, to create the object. The printer builds the object layer by layer, using a process called fused deposition modeling (FDM). The printer melts the material and then deposits it in the desired shape. Once the object is complete, it can be used for a variety of purposes, such as prototyping, manufacturing, and product development. 3D printing has revolutionized the way products are designed and manufactured, allowing for faster production times and more efficient use of materials.

Is 3D printing actually printing?

3D printing is a type of additive manufacturing technology that creates three-dimensional objects by building them up in layers from a digital model. It is also known as additive manufacturing, rapid prototyping, or desktop fabrication. 3D printing is different from traditional printing methods, such as offset printing, lithography, and screen printing, which involve subtractive processes that involve cutting away material to create a desired shape. Instead, 3D printing builds up the object layer by layer, using a variety of materials, including plastics, metals, ceramics, and composites. The process is often referred to as printing because the digital model is sent to the 3D printer, which then prints the object layer by layer. However, 3D printing is not the same as traditional printing, as it does not involve the transfer of ink or toner onto paper. Instead, it is a process of creating a physical object from a digital model.

Is it expensive to use a 3D printer?

The cost of using a 3D printer can vary greatly depending on the type of printer you are using and the materials you are printing with. Generally speaking, 3D printers can range from a few hundred dollars to several thousand dollars. The cost of the printer itself is only part of the equation, however. You will also need to factor in the cost of the materials you are printing with, such as plastic filament, resin, or metal. Additionally, you will need to consider the cost of maintenance and repairs, as well as the cost of electricity to power the printer.

The cost of printing an object will also depend on the size and complexity of the object. Smaller, simpler objects will cost less to print than larger, more complex objects. Additionally, the cost of printing an object will depend on the type of material you are using. For example, printing with plastic filament is generally cheaper than printing with metal or resin.

How much money is a 3D printer?

The cost of a 3D printer can vary greatly depending on the type of printer, the features it offers, and the quality of the printer. Generally speaking, entry-level 3D printers can cost anywhere from $200 to $500, while more advanced 3D printers can cost anywhere from $1,000 to $10,000 or more. The cost of a 3D printer also depends on the type of materials it can print with, as well as the size of the objects it can print. For example, a 3D printer that can print with metal or ceramic materials will cost more than one that only prints with plastic. Additionally, a 3D printer that can print large objects will cost more than one that can only print small objects.

When shopping for a 3D printer, it is important to consider the features and capabilities of the printer, as well as the quality of the printer. It is also important to consider the cost of the materials that the printer will use, as well as the cost of any additional accessories or software that may be needed.

What is the most common 3D printed thing?

The most common 3D printed thing is likely to be a plastic prototype or model. 3D printing is a process of creating three-dimensional objects from a digital file, and it is often used to create prototypes and models of products or parts. This is because 3D printing is a relatively quick and cost-effective way to create a physical representation of a design. It is also used to create custom parts and components for a variety of applications, such as medical devices, automotive parts, and consumer products. 3D printing is also used to create art, jewelry, and other decorative items. In addition, 3D printing is increasingly being used to create functional parts and components for a variety of industries, such as aerospace, automotive, and medical. As 3D printing technology continues to evolve, it is likely that the most common 3D printed thing will continue to change.

Can you 3D print a gun?

3D printing technology has advanced to the point where it is possible to 3D print a gun. 3D printing is a process of creating a three-dimensional object from a digital file. The process involves laying down successive layers of material until the entire object is created. 3D printing technology has been used to create a variety of objects, including guns.

In 2013, a Texas-based company called Solid Concepts created the world’s first 3D printed gun. The gun was made from a combination of metal and plastic parts and was capable of firing live rounds. Since then, other companies have developed 3D printed guns, including a company called Defense Distributed, which created a 3D printed gun called the Liberator.

The legality of 3D printed guns varies from country to country. In the United States, it is legal to 3D print a gun as long as it is not for sale or distribution. However, some states have passed laws that restrict the manufacture, sale, and possession of 3D printed guns.