C&C stands for Computer and Control in manufacturing. It is a term used to describe the use of computers and control systems to automate and optimize the production process. C&C systems are used to monitor and control the production process, from the raw material input to the finished product output. They are also used to monitor and control the quality of the product, as well as the safety of the production environment. C&C systems are used to reduce costs, improve efficiency, and increase the quality of the product. They are also used to reduce the amount of time and labor required to produce a product. C&C systems are used in a variety of industries, including automotive, aerospace, electronics, and medical device manufacturing.

What does C and C mean in manufacturing?

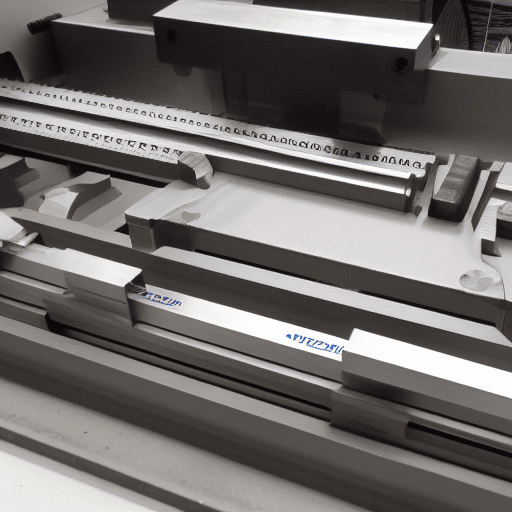

C&C stands for “Computer Numerical Control” and is a type of manufacturing process that uses computers to control machine tools. This type of manufacturing process is used to create parts and components with high precision and accuracy. C&C machines are programmed with a set of instructions that tell the machine how to move and what operations to perform. The instructions are written in a computer language called G-code, which is a numerical code that tells the machine what to do. C&C machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products.

C&C machines are highly automated and can be programmed to perform a variety of tasks, such as drilling, milling, turning, and grinding. They are also capable of performing complex operations, such as 3D printing and laser cutting. C&C machines are used to create parts and components with high precision and accuracy, and they are often used in the production of parts for medical devices, aerospace components, and consumer products.

What does CIS stand for in manufacturing?

CIS stands for Computer Integrated Manufacturing. It is a system of manufacturing that uses computers to control and coordinate the entire production process. This includes the design, planning, scheduling, and execution of all manufacturing operations. It is a form of automation that allows for the integration of all aspects of the production process, from design to delivery. CIS systems are used to reduce costs, improve quality, and increase efficiency. They can also be used to monitor and control production processes, as well as to provide real-time feedback on production performance. CIS systems are used in a variety of industries, including automotive, aerospace, electronics, and medical device manufacturing.

Why is CNC used?

Computer Numerical Control (CNC) is a technology that is used to automate the process of manufacturing products. It is used to control machine tools such as lathes, mills, routers, and grinders, and is used to produce parts with high accuracy and repeatability. CNC machines are programmed with a computer language called G-code, which is a set of instructions that tell the machine what to do. CNC machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products.

CNC machines are used for a variety of reasons. One of the main advantages of CNC machines is that they are able to produce parts with high accuracy and repeatability. This means that parts produced with CNC machines are more consistent and reliable than parts produced with manual methods. CNC machines are also able to produce parts with complex shapes and geometries that would be difficult or impossible to produce with manual methods. Additionally, CNC machines are able to produce parts quickly and efficiently, which can help to reduce production costs.

What are the 4 types of manufacturing processes?

The four types of manufacturing processes are:

1. Casting: Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process. Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods.

2. Machining: Machining is a manufacturing process in which material is removed from a workpiece using power-driven machine tools such as lathes, milling machines, and drill presses. The process can be used to shape or cut a variety of materials, including metal, plastic, and wood.

3. Forming: Forming is a manufacturing process in which a material is shaped by applying a force to it. This force is usually applied with a press or a die. The material is then formed into the desired shape. Common forming processes include forging, extrusion, and stamping.

What is CNC manufacturing?

CNC (Computer Numerical Control) manufacturing is a process that uses computer-controlled machines to produce parts and components with a high degree of accuracy and repeatability. CNC machines are programmed with a set of instructions that tell the machine how to move and shape the material being worked on. The instructions are written in a computer language called G-code, which is a numerical code that tells the machine what to do. CNC machines can be used to produce a wide variety of parts and components, from simple to complex shapes.

CNC machines are typically used in the manufacturing of metal parts and components, but can also be used to produce plastic and composite parts. The process begins with a CAD (Computer Aided Design) drawing of the part or component that is to be produced. This drawing is then converted into a set of instructions that the CNC machine can understand. The instructions are then loaded into the machine, which then begins to move and shape the material according to the instructions.

What are the 4 types of processes?

The four types of processes are:

1. Input Processes: These processes involve the conversion of raw materials, components, or data into a form that can be used by the organization. Examples of input processes include purchasing, receiving, and inventory control.

2. Transformation Processes: These processes involve the conversion of inputs into outputs. Examples of transformation processes include production, assembly, and packaging.

3. Output Processes: These processes involve the conversion of inputs into outputs. Examples of output processes include sales, marketing, and customer service.

4. Feedback Processes: These processes involve the collection and analysis of data to monitor and control the performance of the organization. Examples of feedback processes include quality control, performance measurement, and cost control.

What does C and C stand for?

C and C stands for Command and Control. It is a term used to describe the process of managing and directing the activities of a group of people or machines. It is a type of management system that is used to coordinate the activities of a group of people or machines in order to achieve a common goal. It is often used in military operations, but it can also be used in other areas such as business, manufacturing, and software development.

Command and Control is a type of management system that is based on the principles of command and control theory. This theory states that the most effective way to manage a group of people or machines is to give clear instructions and then monitor the progress of the group. The instructions should be clear and concise, and the monitoring should be done in a systematic way.

Command and Control systems are typically used in situations where there is a need for a high degree of coordination and control.

What CNC means?

CNC stands for Computer Numerical Control, and it is a type of manufacturing process that uses computer-controlled machines to produce parts and components with a high degree of accuracy. CNC machines are programmed with a set of instructions that tell the machine how to move and what operations to perform. The instructions are typically written in a computer language called G-code, which is a language specifically designed for CNC machines. CNC machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products. They are used to produce parts and components with a high degree of accuracy and repeatability, and they can be used to produce parts with complex shapes and intricate details. CNC machines are also used to produce parts with a high degree of precision, which is important for many applications. CNC machines are typically used in conjunction with other machines, such as lathes, mills, and grinders, to produce parts with a high degree of accuracy and repeatability.

What is AC & C machine?

An AC & C machine is a type of automated machine used in the manufacturing industry. It stands for Automated Component and Connector Machine, and is used to assemble components and connectors into a finished product. The AC & C machine is a type of automated assembly line that is used to quickly and accurately assemble components and connectors into a finished product. It is typically used in the electronics industry, but can also be used in other industries such as automotive, medical, and aerospace.

The AC & C machine is a highly automated system that is capable of performing a variety of tasks. It is typically composed of several components, including a robotic arm, a conveyor belt, and a vision system. The robotic arm is used to pick up components and place them in the correct position on the conveyor belt. The vision system is used to detect the components and ensure that they are placed in the correct position. The conveyor belt then moves the components to the next station, where they are connected and assembled into the finished product.

What types of industries use CNC equipment?

CNC (Computer Numerical Control) equipment is used in a wide variety of industries, including automotive, aerospace, medical, electronics, and consumer goods. CNC machines are used to create precision parts and components with high accuracy and repeatability. In the automotive industry, CNC machines are used to create engine components, transmission parts, and other components for cars and trucks. In the aerospace industry, CNC machines are used to create aircraft components, such as landing gear, wings, and fuselages. In the medical industry, CNC machines are used to create medical implants, prosthetics, and other medical devices. In the electronics industry, CNC machines are used to create circuit boards, electronic components, and other electronic products. In the consumer goods industry, CNC machines are used to create products such as furniture, toys, and other consumer products. CNC machines are also used in the manufacturing of tools, such as drill bits, saw blades, and other cutting tools.

Is CNC machining hard?

CNC machining is a complex process that requires a great deal of skill and knowledge to master. It involves programming a computer to control the movement of a machine tool, such as a lathe or milling machine, to cut and shape a variety of materials. The programming language used to control the machine is called G-code, and it can be quite difficult to learn. Additionally, the operator must be familiar with the machine’s capabilities and limitations, as well as the properties of the material being machined.

CNC machining is not necessarily hard, but it does require a great deal of practice and experience to become proficient. It is important to understand the fundamentals of the process, such as the types of tools and cutting techniques used, as well as the safety protocols that must be followed. Additionally, the operator must be able to troubleshoot any issues that may arise during the machining process.

How many types of CNC tools are there?

There are many different types of CNC tools available, and the exact number depends on the specific application. Generally speaking, CNC tools can be divided into two main categories: cutting tools and non-cutting tools.

Cutting tools are used to shape and form materials, and include end mills, drills, reamers, taps, and routers. End mills are used to cut slots, grooves, and pockets in a workpiece, while drills are used to create holes. Reamers are used to enlarge existing holes, and taps are used to create internal threads. Routers are used to cut complex shapes and profiles.

Non-cutting tools are used to support the cutting process, and include tool holders, collets, and chucks. Tool holders are used to secure the cutting tool in the spindle, while collets are used to hold small cutting tools. Chucks are used to hold larger cutting tools, such as drills and reamers.

What language do CNC machines use?

CNC machines use a programming language called G-code. G-code is a numerical control (NC) programming language that is used to instruct CNC machines on how to move and what actions to perform. It is a language that is used to control the motion of machines such as lathes, mills, routers, and grinders. G-code is a language that is used to create a program that can be read by the CNC machine. It is a language that is used to control the motion of the machine, as well as the speed and direction of the cutting tool. G-code is a language that is used to control the machine’s movements, as well as the speed and direction of the cutting tool. G-code is a language that is used to control the machine’s movements, as well as the speed and direction of the cutting tool. G-code is a language that is used to control the machine’s movements, as well as the speed and direction of the cutting tool.

Is a printer CNC?

No, a printer is not a CNC (Computer Numerical Control) machine. A CNC machine is a type of automated machine tool that uses computer programs to control the movement of the machine’s tools. CNC machines are used to produce parts with high precision and accuracy. Examples of CNC machines include milling machines, lathes, routers, and grinders. A printer, on the other hand, is a device that prints text and images onto paper or other media. Printers are typically used to produce documents, photographs, and other printed materials. Printers are not CNC machines and do not use computer programs to control their movements.