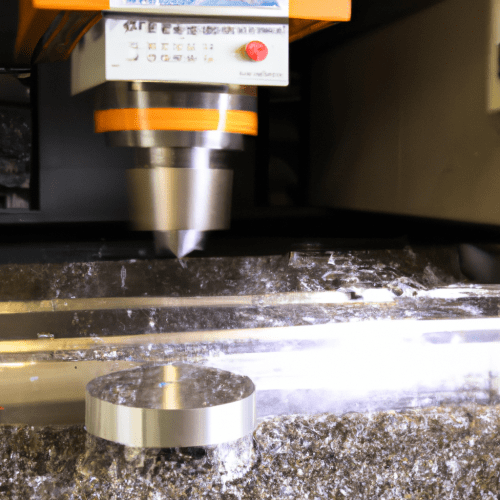

The cost of CNC milling per hour can vary greatly depending on the size and complexity of the project, the type of materials being used, and the type of CNC milling machine being used. Generally speaking, the cost of CNC milling per hour can range from $50 to $500 or more. Smaller projects that require less time and simpler materials may cost as little as $50 per hour, while larger projects that require more time and more complex materials may cost as much as $500 or more per hour. Additionally, the cost of CNC milling per hour may also be affected by the type of CNC milling machine being used. For example, a CNC milling machine with a larger work envelope and more advanced features may cost more per hour than a smaller, less advanced machine. Ultimately, the cost of CNC milling per hour will depend on the size and complexity of the project, the type of materials being used, and the type of CNC milling machine being used.

How do you calculate CNC machining per hour?

CNC machining per hour is calculated by taking the total number of parts produced in an hour and dividing it by the total number of hours it took to produce them. This calculation is important for determining the efficiency of a CNC machine and the cost of production. To calculate CNC machining per hour, you will need to know the total number of parts produced in an hour, the total number of hours it took to produce them, and the cost of production.

First, you will need to determine the total number of parts produced in an hour. This can be done by counting the number of parts that are produced in a given hour and then multiplying that number by the number of hours it took to produce them. For example, if it took two hours to produce 10 parts, then the total number of parts produced in an hour would be 20.

How much does it cost for CNC cutting?

The cost of CNC cutting depends on a variety of factors, including the type of material being cut, the complexity of the design, the size of the project, and the number of parts being cut. Generally, CNC cutting services charge by the hour, with rates ranging from $50 to $150 per hour. The cost of materials is also a factor, as some materials are more expensive than others. For example, aluminum is typically more expensive than steel. Additionally, the cost of CNC cutting can vary depending on the type of machine being used. For example, laser cutting is typically more expensive than plasma cutting.

In general, the cost of CNC cutting can range from a few hundred dollars for a small project to several thousand dollars for a large project. It is important to note that the cost of CNC cutting can vary significantly depending on the complexity of the project and the type of material being cut. Therefore, it is important to discuss the project with a CNC cutting service to get an accurate estimate of the cost.

How is CNC machine pricing calculated?

CNC machine pricing is typically calculated based on a variety of factors, including the type of machine, the size of the machine, the features and capabilities of the machine, and the complexity of the parts that the machine will be used to produce. The cost of the machine will also depend on the manufacturer, the quality of the components, and the availability of parts and service. Additionally, the cost of the machine will be affected by the cost of the materials used to produce the parts, the cost of labor, and the cost of shipping and handling.

When calculating the cost of a CNC machine, it is important to consider the cost of the machine itself, as well as the cost of the software and other components that are necessary to operate the machine. The cost of the software and other components can vary greatly depending on the type of machine and the complexity of the parts that the machine will be used to produce. Additionally, the cost of the machine will be affected by the cost of the materials used to produce the parts, the cost of labor, and the cost of shipping and handling.

Does a CNC machine use a lot of electricity?

A CNC machine is a computer-controlled machine that is used to cut and shape materials such as wood, metal, and plastic. CNC machines are used in a variety of industries, including manufacturing, automotive, aerospace, and medical. As with any machine, the amount of electricity used by a CNC machine depends on the size and type of machine, as well as the type of work it is performing. Generally speaking, CNC machines use a significant amount of electricity, as they require a large amount of power to operate.

The amount of electricity used by a CNC machine is determined by the size of the machine, the type of work it is performing, and the speed at which it is running. For example, a larger CNC machine that is performing complex operations at a high speed will require more electricity than a smaller machine that is performing simpler operations at a slower speed. Additionally, the type of material being cut and shaped will also affect the amount of electricity used. For example, cutting and shaping metal will require more electricity than cutting and shaping wood.

How do you price a CNC project?

Pricing a CNC project can be a complex process, as there are many factors to consider. The first step is to determine the scope of the project. This includes the size of the project, the complexity of the design, the materials needed, and the time required to complete the project. Once the scope is determined, the next step is to determine the cost of the materials needed for the project. This includes the cost of the raw materials, the cost of any additional components, and the cost of any tools or machines needed to complete the project.

The next step is to determine the labor costs associated with the project. This includes the cost of the labor required to complete the project, the cost of any subcontractors needed, and the cost of any additional services needed to complete the project. Once the labor costs are determined, the next step is to determine the overhead costs associated with the project. This includes the cost of any additional equipment needed, the cost of any additional space needed, and the cost of any additional services needed to complete the project.

What is machine hourly rate?

Machine hourly rate is a measure of the cost of running a machine over a given period of time. It is calculated by dividing the total cost of running the machine (including labor, materials, and overhead) by the total number of hours the machine is in operation. The machine hourly rate is an important metric for businesses to track, as it can help them determine the cost-effectiveness of their operations and identify areas where they can reduce costs. It can also be used to compare the cost of running different machines, allowing businesses to make informed decisions about which machines to use for specific tasks. Additionally, machine hourly rate can be used to calculate the cost of producing a certain number of units, allowing businesses to accurately estimate their production costs.

How do you calculate CNC machine time?

Calculating CNC machine time is an important part of the machining process, as it helps to determine the cost of the job and the amount of time it will take to complete. The time it takes to complete a CNC machining job is determined by a variety of factors, including the complexity of the part, the type of material being machined, the size of the part, and the speed of the machine.

To calculate the time it will take to complete a CNC machining job, the first step is to determine the cycle time. Cycle time is the total time it takes to complete one cycle of the machining process, including the time it takes to move the tool from one position to another, the time it takes to cut the material, and the time it takes to retract the tool. This can be calculated by taking the total distance the tool needs to travel and dividing it by the feed rate of the machine.

Once the cycle time has been determined, the next step is to calculate the total time it will take to complete the job.

How do you calculate equipment hourly rate?

Calculating the hourly rate of equipment is an important step in determining the cost of a project. The hourly rate of equipment is the cost of operating the equipment for one hour. It is calculated by dividing the total cost of the equipment by the total number of hours it can be used.

To calculate the hourly rate of equipment, you will need to know the total cost of the equipment, the total number of hours it can be used, and the cost of any additional supplies or services that may be required.

First, you will need to determine the total cost of the equipment. This includes the purchase price, any taxes or fees, and any additional costs associated with the purchase.

Next, you will need to determine the total number of hours the equipment can be used. This includes the time it takes to set up the equipment, the time it takes to operate the equipment, and any additional time needed for maintenance or repairs.

How do you calculate cutting time?

Cutting time is the amount of time it takes to cut a material into a desired shape or size. To calculate cutting time, you need to consider the type of material being cut, the size of the material, the type of cutting tool being used, the speed of the cutting tool, and the depth of the cut.

The type of material being cut will affect the cutting time because different materials require different cutting tools and speeds. For example, cutting metal will require a different cutting tool and speed than cutting wood.

The size of the material being cut will also affect the cutting time. Larger pieces of material will take longer to cut than smaller pieces.

The type of cutting tool being used will also affect the cutting time. Different cutting tools have different speeds and depths of cut, so the type of cutting tool being used will determine how long it takes to cut the material.

The speed of the cutting tool will also affect the cutting time. Faster cutting tools will cut the material faster than slower cutting tools.

How do I calculate my cycle time?

Cycle time is the total amount of time it takes to complete a single cycle of a process. To calculate your cycle time, you need to measure the time it takes to complete each step of the process. Start by measuring the time it takes to complete the first step, then measure the time it takes to complete the second step, and so on. Once you have measured the time for each step, add them together to get the total cycle time. For example, if it takes 10 minutes to complete the first step, 5 minutes to complete the second step, and 15 minutes to complete the third step, then the total cycle time would be 30 minutes.