Machining technology is a manufacturing process that involves the use of specialized tools and machines to shape and cut materials into desired shapes and sizes. It is a subtractive manufacturing process, meaning that material is removed from a workpiece to create the desired shape. Machining technology is used in a variety of industries, including automotive, aerospace, medical, and consumer products.

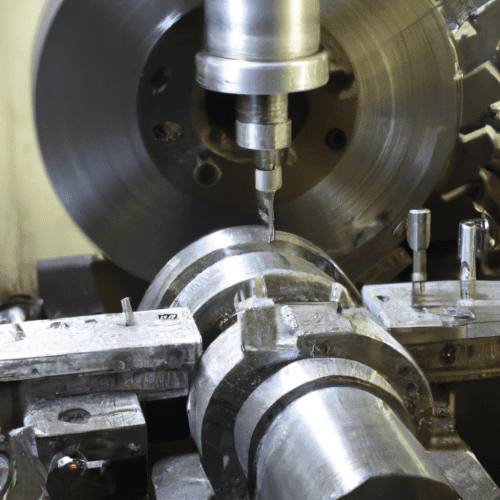

The process of machining typically involves the use of a machine tool, such as a lathe, milling machine, drill press, or CNC machine. The machine tool is used to hold and rotate the workpiece, while a cutting tool is used to remove material from the workpiece. The cutting tool is typically a drill bit, end mill, or router bit, and is guided by the machine tool to create the desired shape.

The machining process can be used to create a variety of shapes and sizes, from simple holes and slots to complex 3D shapes. It can also be used to create intricate details, such as threads, grooves, and other features.

What do you mean by machining?

Machining is a manufacturing process in which a material is cut into a desired shape and size by a controlled material-removal process. It is typically used to produce parts with complex geometries and high tolerances. Machining is one of the most common manufacturing processes, and it is used to produce a wide variety of parts and components for a variety of industries. The process involves the use of a variety of tools, such as lathes, milling machines, drill presses, and grinding machines, to shape and finish the material. The material is typically cut into the desired shape and size by a cutting tool, such as a drill bit, end mill, or router bit. The cutting tool is then moved along the material in a controlled manner to remove material and create the desired shape. The material is then finished by grinding, sanding, or polishing to achieve the desired surface finish. Machining is a versatile process that can be used to produce parts with complex geometries and high tolerances.

What is the principle of machining?

The principle of machining is the process of removing material from a workpiece using a cutting tool to shape and form the workpiece into the desired shape. It is a subtractive manufacturing process, meaning that material is removed from the workpiece in order to create the desired shape. Machining is used in a variety of industries, including automotive, aerospace, medical, and consumer products.

The process of machining involves the use of a cutting tool, such as a drill, mill, lathe, or router, to remove material from the workpiece. The cutting tool is typically made of a hard material, such as high-speed steel or carbide, and is designed to cut through the material of the workpiece. The cutting tool is moved along the surface of the workpiece in a controlled manner, removing material as it goes. The cutting tool is guided by a machine, such as a milling machine or lathe, which controls the speed and direction of the cutting tool.

What is machining in metals?

Machining in metals is a process of removing material from a workpiece to create a desired shape or finish. It is a subtractive manufacturing process, meaning that material is removed from the workpiece to create the desired shape or finish. Machining is used to create parts with complex shapes and features that would be difficult or impossible to create using other manufacturing processes. Common machining processes include turning, milling, drilling, grinding, and sawing. Machining is used in a variety of industries, including automotive, aerospace, medical, and consumer products. Machining is a versatile process that can be used to create a wide range of parts and components. It is also a cost-effective process, as it requires minimal setup and can be used to create parts with complex shapes and features.

What is another word for machining?

Machining is a process of cutting, shaping, and finishing materials to create a desired product. It is a form of subtractive manufacturing, which is the opposite of additive manufacturing. Another word for machining is metalworking, which is the process of working with metals to create a desired product. Metalworking includes machining, as well as other processes such as forging, casting, and welding. Metalworking is a broad term that encompasses many different processes, and machining is just one of them.

How many types of machining are there?

Machining is a manufacturing process in which parts are cut from a workpiece using a variety of tools. It is a subtractive process, meaning that material is removed from the workpiece to create the desired shape. There are many different types of machining processes, each with its own advantages and disadvantages.

The most common types of machining processes include turning, milling, drilling, grinding, sawing, and broaching. Turning is a process in which a rotating tool is used to cut away material from a workpiece. Milling is a process in which a rotating tool is used to cut away material from a workpiece in a variety of directions. Drilling is a process in which a rotating tool is used to create a hole in a workpiece. Grinding is a process in which a rotating tool is used to remove material from a workpiece in order to create a smooth surface. Sawing is a process in which a rotating tool is used to cut away material from a workpiece in a straight line.

What are commonly used machining operations?

Machining operations are a type of manufacturing process that involve the use of specialized tools and machines to shape and cut materials into desired shapes and sizes. Common machining operations include turning, drilling, milling, grinding, sawing, and broaching.

Turning is a machining process that involves rotating a workpiece on a lathe to shape and cut it into a desired shape. It is used to create cylindrical parts with smooth surfaces. Drilling is a machining process that involves using a drill bit to create a hole in a workpiece. It is used to create holes of various sizes and depths. Milling is a machining process that involves using a milling machine to shape and cut a workpiece. It is used to create complex shapes and features on a workpiece. Grinding is a machining process that involves using an abrasive wheel to shape and cut a workpiece. It is used to create smooth surfaces and remove material from a workpiece. Sawing is a machining process that involves using a saw to cut a workpiece.

What are the basic elements of machining?

Machining is a manufacturing process that involves the use of specialized tools and machines to shape and cut materials into desired shapes and sizes. The basic elements of machining include cutting tools, workpiece, machine tool, and cutting fluids.

Cutting tools are the tools used to shape and cut the material. These tools can be made from a variety of materials such as high-speed steel, carbide, and ceramics. The type of cutting tool used depends on the material being machined and the desired shape and size of the finished product.

The workpiece is the material that is being machined. This can be a variety of materials such as metals, plastics, composites, and ceramics. The workpiece is held in place by a workholding device such as a vise, chuck, or fixture.

The machine tool is the machine that is used to shape and cut the material. This can be a variety of machines such as lathes, milling machines, drill presses, and grinders.