Metal machining is a process of cutting and shaping metal materials into desired shapes and sizes. It is a manufacturing process that involves the use of specialized tools and machines to cut and shape metal into the desired shape. Metal machining is used in a variety of industries, including automotive, aerospace, medical, and industrial.

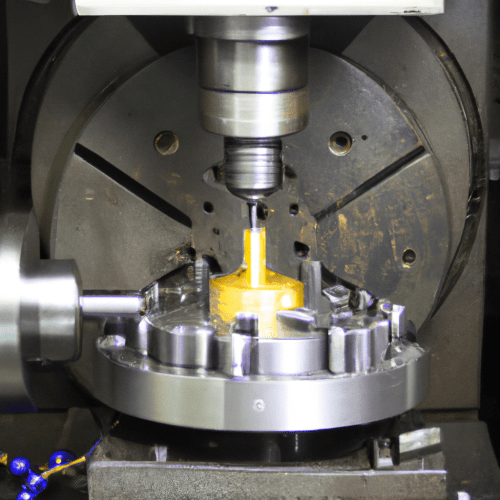

The most common metal machining processes include turning, milling, drilling, tapping, grinding, and sawing. Turning is a process of cutting metal into a desired shape by rotating a cutting tool against the workpiece. Milling is a process of cutting metal into a desired shape by using a rotating cutting tool. Drilling is a process of creating a hole in a workpiece by using a rotating cutting tool. Tapping is a process of creating a threaded hole in a workpiece by using a rotating cutting tool. Grinding is a process of removing material from a workpiece by using an abrasive wheel. Sawing is a process of cutting metal into a desired shape by using a saw blade.

In addition to these processes, metal machining also includes other processes such as broaching, honing, lapping, and EDM (electrical discharge machining). Broaching is a process of cutting metal into a desired shape by using a series of cutting tools. Honing is a process of smoothing the surface of a workpiece by using a rotating abrasive stone. Lapping is a process of smoothing the surface of a workpiece by using a rotating abrasive wheel. EDM is a process of cutting metal into a desired shape by using electrical sparks.

Metal machining is an important process in the manufacturing industry, as it is used to create parts and components for a variety of applications. It is a complex process that requires specialized tools and machines, as well as skilled operators.

What is metal machining?

Metal machining is a process of cutting and shaping metal materials into desired shapes and sizes. It is a manufacturing process that involves the use of specialized tools and machines to remove material from a workpiece in order to create a desired shape or size. The process can be used to create a variety of shapes and sizes, from simple components to complex parts. It is used in a variety of industries, including automotive, aerospace, medical, and industrial.

The process of metal machining begins with the selection of the appropriate material for the job. The material must be strong enough to withstand the forces of machining, and it must be able to be machined to the desired shape and size. Once the material is selected, the machinist will use a variety of tools and machines to cut and shape the material. This includes cutting tools such as drills, milling cutters, and lathes, as well as grinding and polishing tools.

What type of manufacturing is machining?

Machining is a type of manufacturing process that involves the use of specialized tools and machines to shape and cut materials into desired shapes and sizes. It is a subtractive manufacturing process, meaning that material is removed from the workpiece to create the desired shape. Machining is used to create parts for a wide variety of industries, including automotive, aerospace, medical, and consumer products. Common machining processes include milling, turning, drilling, grinding, and broaching. Machining is a versatile process that can be used to create complex shapes and intricate details with high precision and accuracy. It is also a cost-effective way to produce parts in large quantities.

How many types of machining are there?

Machining is a manufacturing process in which parts are cut from a raw material using a variety of tools and techniques. It is a subtractive process, meaning that material is removed from the workpiece to create the desired shape. There are many different types of machining, each with its own advantages and disadvantages.

The most common types of machining are turning, milling, drilling, grinding, and sawing. Turning is the process of cutting a cylindrical shape from a workpiece, usually using a lathe. Milling is the process of cutting a flat surface on a workpiece, usually using a milling machine. Drilling is the process of creating a hole in a workpiece, usually using a drill press. Grinding is the process of removing material from a workpiece using an abrasive wheel. Sawing is the process of cutting a workpiece into two or more pieces, usually using a saw.

Is drilling considered machining?

Drilling is a type of machining process, and is considered a subset of the broader category of machining. Machining is a manufacturing process that involves the use of tools to shape and form materials into desired shapes and sizes. Drilling is a type of machining process that involves the use of a drill bit to cut or shape a material. The drill bit is rotated at high speeds and is pressed against the material to create a hole or cavity. Drilling is used to create holes in a variety of materials, including metals, plastics, and wood. It is also used to create threads in materials, such as screws and bolts. Drilling is a relatively simple process and is often used in the production of a variety of products, from furniture to automotive parts. Drilling is a cost-effective way to create precise holes and is often used in combination with other machining processes, such as milling and turning, to create complex shapes and components.

What is metal cutting called?

Metal cutting is a process used to shape and form metal into a desired shape or size. It is also known as metalworking, machining, or fabrication. Metal cutting is used in a variety of industries, including automotive, aerospace, construction, and manufacturing. The process involves using a variety of tools and techniques to cut, shape, and form metal into the desired shape or size.

The most common metal cutting tools are saws, drills, lathes, milling machines, and shears. Saws are used to cut metal into straight lines, while drills are used to create holes in metal. Lathes are used to shape metal into curved shapes, while milling machines are used to create intricate shapes and patterns. Shears are used to cut metal into thin strips.

The process of metal cutting involves a variety of techniques, including cutting, grinding, drilling, and tapping. Cutting is the process of removing material from the workpiece using a cutting tool. Grinding is the process of removing material from the workpiece using an abrasive wheel.

What is machining processes?

Machining processes are a type of manufacturing process that involve the use of specialized tools and machines to shape and cut materials into desired shapes and sizes. Machining processes are used to create parts for a wide variety of industries, including automotive, aerospace, medical, and industrial. The most common machining processes include turning, milling, drilling, grinding, and sawing.

Turning is a machining process that involves rotating a workpiece on a lathe while a cutting tool is used to remove material from the workpiece. This process is used to create cylindrical parts with a uniform diameter and shape.

Milling is a machining process that involves using a rotating cutting tool to remove material from a workpiece. This process is used to create parts with complex shapes and features.

Drilling is a machining process that involves using a rotating drill bit to create holes in a workpiece. This process is used to create holes of various sizes and depths.

Grinding is a machining process that involves using an abrasive wheel to remove material from a workpiece.

What is the importance of machining in the metal industry?

Machining is an essential process in the metal industry, as it is used to shape and form metal into the desired shape and size. Machining is used to create components for a variety of industries, including automotive, aerospace, medical, and industrial. It is also used to create parts for consumer products, such as appliances and electronics.

The importance of machining in the metal industry lies in its ability to create precise and accurate parts. Machining is a subtractive process, meaning that it removes material from a workpiece to create the desired shape and size. This allows for parts to be created with a high degree of accuracy and precision. Machining also allows for complex shapes to be created, which would be difficult or impossible to create with other manufacturing processes.

Machining is also important in the metal industry because it is a relatively fast process. It is much faster than other manufacturing processes, such as casting or forging, which can take days or weeks to complete. This makes machining an ideal choice for creating parts with tight deadlines.

What is metal fabrication process?

Metal fabrication is the process of forming and shaping metal components into a desired shape or structure. It involves cutting, bending, welding, and assembling metal parts to create a finished product. The process can be used to create a variety of products, from small components to large structures.

The metal fabrication process begins with the selection of the material to be used. This could be a variety of metals, such as steel, aluminum, copper, brass, or titanium. The material is then cut into the desired shape and size using a variety of tools, such as saws, shears, and presses. The pieces are then bent and formed into the desired shape using a variety of tools, such as hammers, presses, and rollers.

Once the pieces are formed, they are welded together using a variety of welding techniques, such as arc welding, gas welding, and spot welding. The welded pieces are then inspected for quality and accuracy. If necessary, additional pieces may be added to the structure to create the desired shape or structure.