A CNC lathe machine is a computer-controlled precision tool used in manufacturing to create cylindrical parts with high accuracy and efficiency. It operates by rotating a workpiece while cutting tools move along various axes to remove material and shape the part according to programmed specifications. CNC lathes are capable of performing a wide range of operations, including turning, facing, threading, drilling, and boring, often combining multiple processes in a single setup. These machines are extensively used in industries such as aerospace, automotive, and general manufacturing to produce components like shafts, bolts, pipes, and custom parts.

The CNC system allows for complex geometries and repeatable results, significantly reducing human error and increasing productivity. Modern CNC lathes often feature advanced capabilities like live tooling, multi-axis control, and automated tool changing, enabling them to create intricate parts with minimal operator intervention. Their versatility, precision, and ability to handle both small and large production runs make CNC lathes indispensable in modern machining operations.

- A CNC lathe machine is a type of computer numerical control (CNC) machine that automates the control of machine tools through software embedded in a microcomputer.

- It eliminates the need for manual operation and produces products using coded instructions.

- CNC lathe machines are commonly used in manufacturing processes and can vary in size, function, and design.

- They offer precise and efficient machining capabilities, making them essential tools in industries such as automotive, aerospace, electronics, and healthcare.

- The use of CNC lathe machines improves productivity, accuracy, and repeatability, leading to cost and time savings for manufacturers.

Different Types of Lathe Machines

When it comes to lathe machines, there are different types available in the market. Two popular categories are conventional lathes and CNC lathe machines. Let’s take a closer look at each type:

1. Conventional Lathe Machine

A conventional lathe machine is manually operated by a skilled technician who has the expertise to handle the machine’s movements. This type of machine requires hands-on control from the operator for the machining process.

2. CNC Lathe Machine

A CNC lathe machine, on the other hand, operates through a software program that controls its functions, resulting in automation and increased precision. CNC stands for Computer Numerical Control, and it uses coded instructions to operate the machine with minimal manual intervention.

Compared to conventional lathes, CNC lathe machines offer numerous advantages. They provide enhanced accuracy, repeatability, and the ability to perform complex tasks with ease. With a CNC lathe machine, the operator’s primary tasks involve loading materials, inspecting the product, and ensuring smooth operation.

Now that we have explored the different types of lathe machines, in the next section, we will focus on the versatility and applications of CNC lathe machines.

Versatility and Applications of CNC Lathe Machines

CNC lathe machines are highly versatile and find applications in various industries, including automotive, healthcare, electronics, and aerospace. These machines have the capability to produce a wide range of products, from large items like automobile frames and airplane engines to smaller items like surgical instruments, gears, and garden tools.

One of the key advantages of CNC lathe machines is their ability to create flat surfaces, threads, and cylindrical components with both inner and outer diameters. This versatility allows for the efficient production of diverse parts and components that meet the specific requirements of different industries.

The applications of CNC lathe machines are extensive and crucial in several industries:

Automotive Industry

- Manufacturing engine components

- Producing transmission parts

- Creating drive shafts

Healthcare Industry

- Producing surgical instruments

- Manufacturing medical implants

- Creating prosthetics

Electronics Industry

- Producing electronic connectors

- Manufacturing circuit board components

- Creating precision gears for electronic devices

Aerospace Industry

- Manufacturing turbine blades

- Creating landing gear components

- Producing structural aircraft parts

When it comes to CNC lathe machines, the number of axes plays a crucial role in their capabilities. Machines with multiple axes can perform advanced operations such as milling, tapping, drilling, and boring, expanding their applications and allowing for more complex and intricate designs.

The following table provides a summary of the applications of CNC lathe machines in different industries:

| Industry | Applications |

|---|---|

| Automotive | Engine components, transmission parts, drive shafts |

| Healthcare | Surgical instruments, medical implants, prosthetics |

| Electronics | Electronic connectors, circuit board components, precision gears |

| Aerospace | Turbine blades, landing gear components, structural aircraft parts |

As seen in the table, CNC lathe machines play a vital role in the manufacturing processes of various industries, enabling efficient production and ensuring the creation of high-quality, precise components.

How CNC Lathe Machines Work

CNC lathe machines are highly versatile and efficient tools that encompass a range of features and functions. Understanding how these machines operate is essential for optimizing their capabilities in precision machining. Let’s delve into the workings of CNC lathe machines and explore their key features.

Main Components of CNC Lathe Machines

CNC lathe machines consist of several essential components that work seamlessly together to achieve precise machining outcomes. These components include:

- Machine Bed: The sturdy foundation that supports all other machine components.

- Main Spindle: The rotating shaft that holds the workpiece and performs cutting operations.

- Sub-Spindle: An additional spindle that allows for simultaneous machining on both ends of the workpiece.

- Chuck: The clamping device that securely holds the workpiece in place.

- Guide Way: The linear motion system that enables smooth and accurate movement of the cutting tools.

- Headstock: The assembly that houses the main spindle, sub-spindle, and chuck.

- Tailstock: The movable component used for supporting long workpieces during machining.

- Tool Turret: The tool holder that carries various cutting tools, allowing for efficient tool changes.

- CNC Controller: The electronic control panel that stores and executes machining programs.

These components work in harmony to ensure precise movements and cutting actions, resulting in accurate and high-quality machined parts.

Programming and Functions of CNC Lathe Machines

CNC lathe machines are programmable, enabling operators to input specific instructions for machining operations. These machines offer a wide range of functions, allowing for diverse machining capabilities. Some common functions of CNC lathe machines include:

- Turning: The process of rotating the workpiece while cutting tools shape its outer surface.

- Facing: The operation of cutting across the end surface of the workpiece to achieve a flat and smooth finish.

- Drilling: Creating holes in the workpiece using specialized drill bits.

- Tapering: Gradually reducing or increasing the diameter of the workpiece.

- Threading: Cutting threads onto the workpiece to create screw-like features.

With these functions at their disposal, machinists can precisely shape and form workpieces according to design specifications.

Configurations and Advanced Features

CNC lathe machines come in various configurations to meet different machining requirements. These configurations include:

| Configuration | Description |

|---|---|

| Horizontal | The spindle is positioned parallel to the ground, allowing for efficient chip evacuation. |

| Vertical | The spindle is positioned perpendicular to the ground, making it ideal for certain machining operations. |

| Slant Bed | The machine bed is angled, providing enhanced stability and improved chip removal. |

| Flat Bed | The machine bed is flat, offering versatility and ease of use. |

Additionally, CNC lathe machines can possess multiple axes, spindles, and even a b-axis capability for five-axis index milling. These advanced features broaden the range of machining possibilities and enable machinists to complete complex tasks with precision and efficiency.

https://www.youtube.com/watch?v=jF4F8Zr2YO8

Benefits of Using CNC Machines

CNC lathe machines offer numerous advantages over conventional machines in the manufacturing industry. The precision and accuracy provided by CNC machines ensure consistent and high-quality results. Automation and efficiency significantly increase productivity while reducing labor requirements. CNC machines are also highly versatile, capable of handling different workpiece sizes and shapes. This versatility allows manufacturers to produce a wide variety of products using a single machine.

One of the significant benefits of CNC machines is the time and cost savings they offer. With reduced machining time and the elimination of human errors, manufacturers can streamline their production processes and meet deadlines more efficiently. The accuracy and repeatability provided by CNC machines enable them to perform complex operations with utmost precision, ensuring the production of intricate and intricate components.

Here are the key benefits of using CNC machines:

- High precision and accuracy

- Automation and increased productivity

- Versatility in handling different workpiece sizes and shapes

- Time and cost savings through reduced machining time and elimination of human errors

- Capability to perform complex operations with high precision and repeatability

CNC machines have revolutionized the manufacturing industry by offering improved efficiency, productivity, and quality. They have become an indispensable tool for various industries, including automotive, aerospace, electronics, and healthcare.

| Advantages of Using CNC Machines |

|---|

| High precision and accuracy |

| Automation and increased productivity |

| Versatility in handling different workpiece sizes and shapes |

| Time and cost savings through reduced machining time and elimination of human errors |

| Capability to perform complex operations with high precision and repeatability |

SYIL’s Precision CNC Machines for Milling and Drilling

When it comes to precision machining, SYIL Machine Tools is a name that stands out. They are renowned manufacturers of state-of-the-art CNC machines for milling and drilling, offering exceptional accuracy and efficiency in various machining operations.

SYIL’s CNC machines are designed to deliver unparalleled precision, reliability, and durability. Whether it’s milling or drilling, their machines are equipped to handle these tasks with exceptional results. What sets SYIL apart is their commitment to convenience. They have developed machines that can perform both milling and drilling operations, eliminating the need for separate equipment.

SYIL’s precision CNC machines are not only efficient, but they also prioritize sustainability. The company incorporates energy-efficient components in their manufacturing processes, minimizing environmental impact. Moreover, they promote responsible disposal practices, ensuring a greener future.

Getting Started with CNC Lathe Work

To embark on your CNC lathe work journey, it’s crucial to start with the right machine that meets your specific needs. There are a few essential factors to consider when selecting a CNC lathe machine: project size, materials, and budget. By carefully assessing these elements, you can make an informed decision that will enable smooth operations and optimal outcomes.

One reputable manufacturer known for its global reach and high-quality CNC lathe machines is SYIL Machine Tools. With a strong reputation in the industry, SYIL offers reliable and efficient machines that cater to various machining requirements. Their machines are designed to deliver exceptional precision and durability, making them a go-to choice for many professionals.

Once you have obtained the suitable CNC lathe machine, it’s essential to familiarize yourself with its key components and functionalities. Understanding the machine’s components, such as the machine bed, spindle, chuck, and tool turret, will enable you to operate it effectively. Additionally, it’s crucial to prioritize safety by following proper safety measures and protocols.

Moreover, gaining knowledge of programming is vital in achieving accurate and precise results. Learning how to program the CNC lathe machine enables you to input the instructions and commands necessary for the desired machining tasks. Mastering these programming skills will enable you to optimize the machine’s capabilities and enhance efficiency in your work.

This section will now guide you through the various steps involved in operating a CNC lathe machine, providing you with a comprehensive understanding of how to harness its power effectively. Let’s delve into the step-by-step process of operating these remarkable machines.

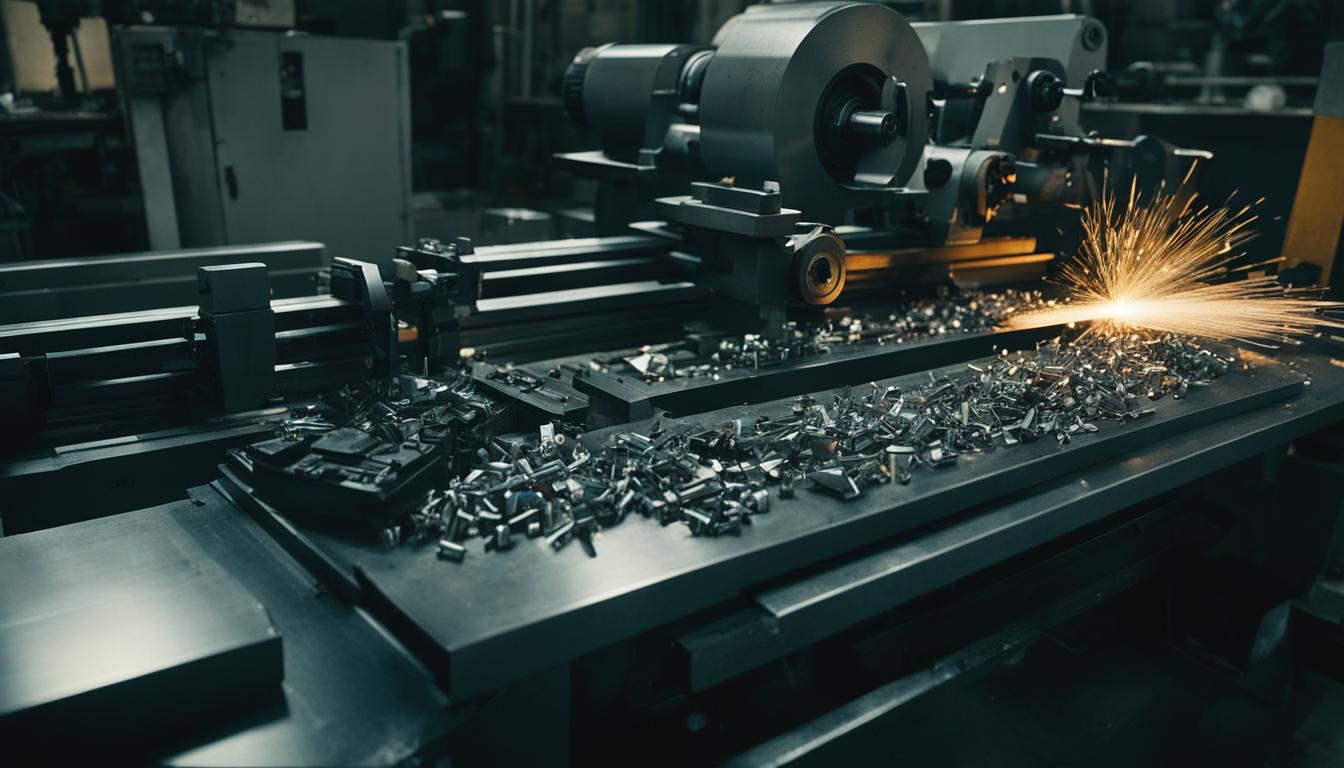

#include image

Operating a CNC Lathe Machine: Step-by-Step Guide

Operating a CNC lathe machine requires a systematic approach to ensure precision and efficiency. By following a step-by-step guide, you can learn how to operate these machines effectively and achieve accurate results.

Step 1: Set up the Machine

Begin by setting up the CNC lathe machine according to the specific requirements of your project. This includes properly securing the workpiece and ensuring that all necessary tools and materials are readily available.

Step 2: Load the Materials

Next, carefully load the materials onto the machine. Ensure that they are securely fastened, preventing any movement or accidents during the machining process. Pay attention to the alignment and positioning to ensure accurate cutting.

Step 3: Program the Machine

Program the CNC lathe machine by inputting the necessary commands and adjusting the settings. This programming process dictates the precise movements and actions the machine will perform. Pay close attention to details such as feed rates and cutting depths to achieve the desired results.

Step 4: Execute Precise Cuts

Once the machine is properly programmed, execute the cuts as per the programmed instructions. Monitor the process closely to ensure that everything is running smoothly and that the cuts are being made accurately.

Step 5: Follow Safety Measures

Throughout the entire operation, it is essential to prioritize safety. Always follow safety measures and precautions, such as wearing appropriate protective gear, avoiding distractions, and adhering to the machine’s safety guidelines. This will help ensure the operator’s well-being and prevent accidents.

Step 6: Practice and Improve

Proficiency in operating a CNC lathe machine comes with practice and experience. Continuously strive to improve your skills and familiarize yourself with the machine’s capabilities and intricacies. Invest time in learning advanced techniques and exploring new features to further enhance your proficiency.

By following this step-by-step guide and dedicating time to practice, you can become proficient in operating a CNC lathe machine and achieve exceptional results in precision machining.

Advanced Features and Capabilities of CNC Lathe Machines

CNC lathe machines are equipped with advanced features and capabilities that revolutionize precision machining. These cutting-edge technologies elevate productivity and expand the possibilities for manufacturers.

Automatic Tool Changers

One of the advanced features of CNC lathe machines is their automatic tool changers. This feature allows the machine to switch between different tools seamlessly, eliminating the need for manual tool changes. The automatic tool changer enhances efficiency and reduces downtime, enabling continuous machining operations.

Live Tooling Capabilities

In addition to automatic tool changers, CNC lathe machines offer live tooling capabilities. This means that the machine can perform secondary operations like milling, drilling, and tapping without the need for an additional tool or setup. Live tooling expands the capabilities of CNC lathe machines, enabling manufacturers to produce complex parts with reduced setup time.

Multi-Axis Functionality

CNC lathe machines are designed with multi-axis functionality, allowing for enhanced flexibility and precision. By incorporating additional axes of movement, these machines can perform intricate operations and produce complex geometries. Multi-axis CNC lathe machines enable manufacturers to create intricately shaped components with high accuracy.

SYIL Machine Tools, a leading manufacturer of CNC lathe machines, excels in incorporating advanced features into their machines. Their dedication to continuous innovation drives the development of cutting-edge CNC lathe technology that empowers manufacturers to achieve exceptional precision and efficiency.

| Advanced Features | Capabilities |

|---|---|

| Automatic Tool Changers | Seamless tool changes, enhanced efficiency |

| Live Tooling Capabilities | Secondary operations without additional tools or setups |

| Multi-Axis Functionality | Intricate operations and complex geometries |

Applications of CNC Lathe Machines

CNC lathe machines play a crucial role in various industries, including automotive, aerospace, medical, electronics, and general manufacturing. In the automotive industry, these machines are utilized to manufacture high-precision engine components and transmission parts. Their ability to create intricate shapes and achieve tight tolerances ensures the production of quality components for vehicles.

In the aerospace sector, CNC lathe machines are employed to produce critical parts such as turbine blades and landing gear components. The precise and efficient machining capabilities of these machines contribute to the safety and performance of aircraft. The medical industry also relies on CNC lathe machines to create precision parts for medical devices, ensuring accuracy and reliability in healthcare applications. These machines are able to manufacture complex components required for devices like surgical instruments and implantable devices.

Furthermore, CNC lathe machines find wide applications in the electronics industry, enabling the production of intricate parts for electronic devices such as connectors, switches, and PCB components. Their versatility and speed make them ideal for manufacturing precise components in this fast-paced industry. Additionally, CNC lathe machines are extensively utilized in general manufacturing processes, ranging from the production of consumer goods and machinery components to the creation of intricate parts for various industries.