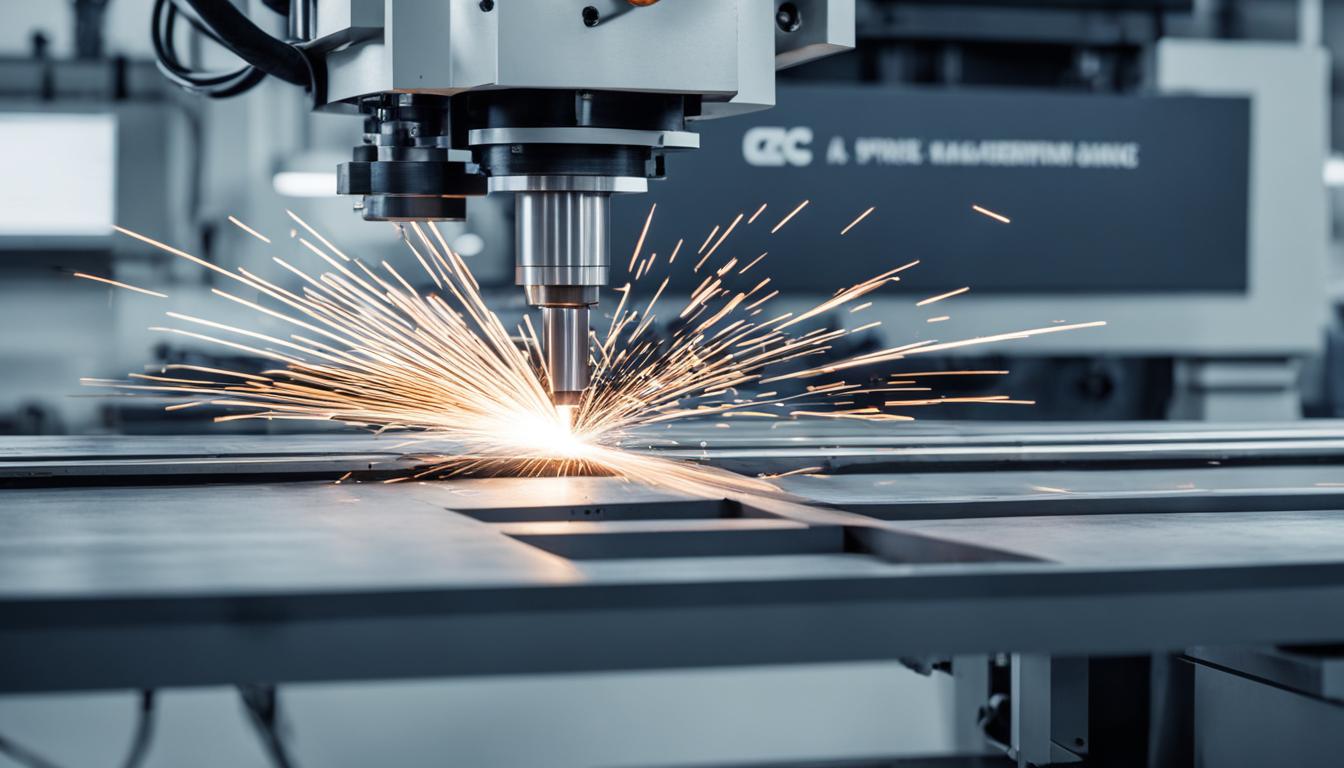

CNC bending machines are advanced manufacturing tools that use computer numerical control to precisely bend sheet metal and tubes into desired shapes. These machines automate the bending process by employing a computer-controlled hydraulic system to shape components with consistent accuracy. The CNC system allows for complex bends and shapes to be programmed and executed repeatedly, ensuring high precision and uniformity across production runs.

Typical CNC bending machines consist of a frame, a working table, bending tools (like punches and dies), and a control panel. They can handle materials of various thicknesses and sizes, from small sheets to large metal plates. The process begins with inputting the desired bend specifications into the machine’s computer, which then controls the movement of the bending tools to achieve the exact angles and shapes required.

This automation significantly reduces human error, increases production speed, and allows for intricate designs that would be difficult or impossible to achieve manually. CNC bending machines are widely used in industries such as automotive, aerospace, construction, and electronics manufacturing, where precision and consistency in metal forming are crucial.

- A CNC bending machine is a highly efficient and precise automated system used for shaping sheet metal and tubes into precise components.

- These machines offer numerous advantages, including improved accuracy, a wide range of applications, and the ability to work with various sizes and types of metal.

- CNC bending machines find applications in industries such as aerospace, automotive, medical, agriculture, and power sports vehicles.

- The benefits of CNC bending include cost reduction, time savings, and the production of consistent and accurate components.

- Accurl is a renowned manufacturer known for its high-quality CNC bending machines with advanced control systems and customizable features.

What Is CNC Bending?

CNC bending is a highly efficient fabrication method that utilizes CNC machines to shape sheet metal and tubes into desired components. These machines offer a range of features and benefits that make them essential tools in the manufacturing industry.

Key features of CNC bending machines include:

- Full Automation: CNC bending machines are fully automated, allowing for precise control of the bending process. This automation ensures consistent and accurate results, reducing the need for manual labor.

- Wide Range of Applications: These machines can handle various sizes and shapes of metal, making them versatile for different applications. Whether it’s simple bends or complex geometries, CNC bending machines can accommodate diverse fabrication needs.

Matching the right machine with the appropriate metal size and strength is crucial for achieving desired results. CNC bending machines offer numerous benefits, including:

- Cost Reduction: By automating the bending process, CNC machines help reduce labor costs and minimize material waste. This leads to significant cost savings for manufacturers.

- Time Savings: CNC bending machines operate at high speeds, completing the bending process quickly. This results in improved production efficiency and shorter lead times.

- Consistent and Accurate Components: The precise control offered by CNC bending machines ensures the production of consistent and accurate components. This eliminates variations that may occur with manual bending, leading to higher quality products.

Overall, CNC bending machines offer advanced features, versatile applications, and numerous benefits, making them indispensable tools in the manufacturing industry.

Benefits of CNC Bending

CNC bending machines offer several advantages in the manufacturing industry. The automated nature of the process reduces labor requirements and ensures consistent and accurate components. This leads to cost reduction, as fewer laborers are needed and there is less material waste. Additionally, the time saved by using CNC machines speeds up the production process and improves overall efficiency. The ability to produce consistent and accurate components also contributes to higher quality products.

As shown in the table below, CNC bending machines provide numerous benefits that enhance productivity, reduce costs, and improve the quality of manufactured components.

| Advantages of CNC Bending Machines |

|---|

| 1. Automated process reduces labor requirements |

| 2. Ensures consistent and accurate components |

| 3. Cost reduction through reduced labor and material waste |

| 4. Time savings and increased production efficiency |

| 5. Higher quality products with consistent and accurate components |

Industries that Use CNC Bending

As CNC bending machines offer time and labor-saving capabilities, they are widely utilized in various industries. These machines play a crucial role in providing high-quality components that can withstand the demanding conditions of industries such as aerospace, automotive, medical, agriculture, and power sports vehicles. CNC bending machines ensure precision and consistency in the production of these components, making them an ideal choice for these sectors. Moreover, the versatility of CNC bending machines allows for their application across a wide range of industries, catering to diverse needs and requirements.

These machines have transformed the manufacturing processes of many industries, enabling the production of complex and precise parts. Let’s take a closer look at how CNC bending machines are utilized in some key industries:

- Aerospace: CNC bending machines are used to manufacture aircraft components such as airframe parts, structural elements, and brackets. They ensure the production of accurate and reliable parts that meet the stringent requirements of the aerospace industry.

- Automotive: The automotive industry relies on CNC bending machines for the production of exhaust systems, chassis components, and body panels. These machines enable the manufacturing of high-quality parts with consistent bends, contributing to the overall performance and safety of vehicles.

- Medical: CNC bending machines play a vital role in the production of medical devices and equipment, including surgical instruments, implantable components, and medical tubing. The precision and accuracy provided by these machines ensure the reliability and functionality of medical devices.

- Agriculture: CNC bending machines are utilized in the agricultural sector for the fabrication of equipment such as agricultural machinery frames, supports, and brackets. These machines enable the production of sturdy and durable components that withstand the harsh conditions of agricultural operations.

- Power Sports Vehicles: CNC bending machines are essential in the manufacturing of power sports vehicles such as motorcycles, ATVs, and snowmobiles. They are used for producing components like frames, handlebars, and exhaust systems, ensuring the reliable performance and safety of these vehicles.

These industries represent just a few examples of the broad range of applications and uses for CNC bending machines. Their adaptability and precision make them indispensable in various sectors, enabling the efficient and reliable production of high-quality components.

CNC Bending Process Capabilities

VPIC, a leading CNC manufacturer, offers a wide range of CNC machining services, including CNC bending. With their state-of-the-art technology and expertise, they provide superior capabilities in creating precision components for various industries. Utilizing advanced CNC bending machine technology, VPIC ensures efficient and accurate bending processes, resulting in high-quality end products.

Their CNC bending process encompasses the use of lathe machines, milling machines, wire EDM, and other cutting-edge manufacturing processes. This comprehensive approach allows VPIC to cater to diverse customer requirements and deliver customized solutions.

VPIC’s in-house CNC bending capabilities provide significant time and cost savings for their customers. By eliminating the need for outsourcing, they streamline the production process and ensure prompt delivery of components. This efficiency, coupled with their commitment to precision component manufacturing, makes VPIC a trusted partner for companies seeking tailored CNC bending solutions.

If you’re looking for a reliable CNC manufacturer that combines cutting-edge technology, extensive capabilities, and exceptional customer service, VPIC is the ideal choice. Their expertise in CNC bending machine technology and their dedication to meeting customer needs make them a preferred provider in the industry.

Key Characteristics of VPIC’s CNC Bending Process

| Characteristic | Description |

|---|---|

| Advanced CNC Machines | The utilization of cutting-edge CNC machines ensures precise and consistent bending processes. |

| Wide Range of Manufacturing Processes | VPIC employs various manufacturing processes, including lathe machines, milling machines, and wire EDM, to accommodate diverse customer requirements. |

| In-House Capabilities | With in-house CNC bending capabilities, VPIC eliminates the need for outsourcing, resulting in time and cost savings for their customers. |

| Precision Component Manufacturing | VPIC’s commitment to precision ensures the creation of high-quality components tailored to customer specifications. |

| Customer-Focused Approach | VPIC prioritizes customer service, providing personalized solutions and exceptional support throughout the CNC bending process. |

How CNC Bending Machines Work

CNC bending machines have become increasingly popular in the manufacturing industry due to their ease of use and technological advancements. These machines operate based on specific working principles that enable precise and efficient bending of sheet metal and tubes. Understanding how CNC bending machines work is essential for operators and manufacturers looking to optimize their bending processes.

When operating a CNC bending machine, it is crucial to prioritize safety precautions and adhere to proper operating procedures. The operator should begin by ensuring the stability and normal functioning of the machine and its components. This includes checking the hydraulic system, control panel, and safety features to prevent any potential accidents during operation.

Once the machine is deemed stable, the next step involves positioning the sheet metal or tube correctly. Precise positioning is critical for achieving accurate and consistent bends. CNC bending machines feature various mechanisms for securing the material, such as clamps or holders, to ensure it remains in place throughout the bending process.

After positioning the material, the bending process can be initiated. The operator programs the desired bending angle and dimensions into the machine’s control panel. This programming can be done through dedicated software or manually inputting the values. The CNC bending machine then uses its hydraulic system and computer control to apply the necessary force to bend the material to the specified angle.

During the bending process, it is important to follow certain safety measures to avoid accidents and ensure the quality of the bent components. One such measure is to avoid lifting the sheet or tube while it is being bent, as this can lead to unstable bending and potential damage to the material.

Additionally, when making adjustments to the machine or the bending process, it is crucial to cut off the power supply to prevent any unintentional movements or operations. This ensures the operator’s safety and prevents any potential damage to the machine.

Regular maintenance and quality checks are also essential for the proper operation of CNC bending machines. This includes inspecting and lubricating the machine’s components, checking for any signs of wear or damage, and verifying the accuracy of the bending angles and dimensions.

By understanding the working principles of CNC bending machines and following proper operating procedures, manufacturers can maximize the efficiency and accuracy of their bending processes. These machines offer numerous benefits, such as increased productivity, cost-effectiveness, and the production of high-quality components.

CNC Bending Machine Features and Customization

When it comes to CNC bending machines, one size does not fit all. That’s why manufacturers like Accurl offer a range of features and customization options to meet specific needs. Accurl is renowned for its high-end CNC bending machines that combine advanced technology with user-friendly functionalities. Let’s explore some of the notable features and customization options available:

1. Advanced Control Systems

Accurl’s CNC bending machines are equipped with advanced control systems that provide precise and efficient operation. These systems allow for easy programming, accurate bend angles, and real-time monitoring of the bending process. With user-friendly interfaces and intuitive controls, operators can optimize productivity and achieve exceptional accuracy.

2. Back Gauge Adjustments

The back gauge is a critical component in CNC bending machines, ensuring accurate positioning of the sheet or tube during bending. Accurl machines offer precise back gauge adjustments that allow for consistent and repeatable bends. This feature ensures reliable bend angles and eliminates errors caused by manual measurements.

3. Reliable Crowning Systems

To overcome the deformation caused by the downward pressure during the bending process, Accurl CNC bending machines are equipped with reliable crowning systems. These systems dynamically adjust the beam to compensate for material spring-back, resulting in accurate and uniform bends across the entire workpiece.

4. Safety Features

Accurl prioritizes operator safety by incorporating various safety features into their CNC bending machines. These include safety guards, light curtains, emergency stop buttons, and user-friendly interfaces that promote safe operation. By taking safety seriously, Accurl ensures a secure working environment for operators.

| Features | Benefits |

|---|---|

| Advanced Control Systems | – Precise and efficient bending process – Easy programming and real-time monitoring |

| Back Gauge Adjustments | – Accurate positioning for consistent bends – Elimination of manual measurement errors |

| Reliable Crowning Systems | – Compensation for material spring-back – Uniform bends across the workpiece |

| Safety Features | – Promotes operator safety – Secure working environment |

5. Customization Options

In addition to these essential features, Accurl CNC bending machines offer customization options to meet specific requirements. These options can include specialized tooling apps for increased efficiency and inventory management. By tailoring the machines to individual needs, businesses can optimize productivity and streamline their bending operations.

6. Eco-Friendly Practices

Accurl is committed to eco-friendly manufacturing practices. Their CNC bending machines come with innovative features like Hybrid Eco Function and active angle control. These features help reduce energy consumption, minimize material waste, and contribute to sustainable production processes.

With the wide range of features and customization options available, Accurl CNC bending machines provide businesses with the tools they need to achieve precise and efficient bending operations while promoting safety and sustainability.

Back Gauge Adjustment and Stroke Adjustment

In CNC bending machines, two critical features contribute to the precision and flexibility of the bending process: back gauge adjustment and stroke adjustment. These features play a vital role in ensuring accurate positioning of the sheet or tube during bending, resulting in high-quality components.

Back gauge adjustment allows operators to fine-tune the position of the back gauge, which supports the material being bent. By adjusting the back gauge, the operator can achieve the desired bend line accurately. This adjustment compensates for material elongation, ensuring consistent and precise bends.

Stroke adjustment, on the other hand, involves setting the stroke length of the machine to match the required bending action. The stroke is the distance the ram travels during the bending process. By adjusting the stroke length, operators can achieve optimal bending angles and accurately shape the components.

Both back gauge and stroke adjustments can be performed either manually or using electric quick-adjustment features, depending on the machine’s capabilities. Manual adjustments provide operators with fine control over the bending process, while electric quick-adjustment features offer increased efficiency and productivity.

Benefits of Back Gauge Adjustment and Stroke Adjustment

The combination of back gauge adjustment and stroke adjustment in CNC bending machines offers several benefits:

- Precision: Accurate positioning of the back gauge and stroke length ensures precise and consistent bends, resulting in high-quality components.

- Flexibility: The ability to adjust the back gauge and stroke length provides flexibility in accommodating different material sizes and bending requirements.

- Efficiency: Electric quick-adjustment features enable operators to swiftly make adjustments, saving time and increasing overall productivity.

- Customization: Fine control over the bending process allows for customization, meeting specific design requirements and delivering tailored solutions.

Comparison of Back Gauge Adjustment and Stroke Adjustment

| Back Gauge Adjustment | Stroke Adjustment |

|---|---|

| Allows for precise positioning of the back gauge to achieve accurate bend lines | Enables setting of the stroke length to match the required bending action |

| Compensates for material elongation, resulting in consistent bends | Provides flexibility in bending angles and shapes |

| Can be adjusted manually or using electric quick-adjustment features | Offers both manual and electric quick-adjustment capabilities |

| Increases precision and accuracy in bending operations | Facilitates efficient bending process and higher productivity |

CNC Bending Machine for Angle Bending and Imprint Bending

CNC bending machines offer specialized solutions for angle bending and imprint bending, catering to diverse applications in various industries. These machines leverage CNC technology to deliver precise and consistent bends, ensuring high angle accuracy and complex bend formations.

Angle Bending Machines

Angle bending machines are designed to bend materials at specific angles with utmost precision. With their advanced CNC capabilities, these machines guarantee accurate and repeatable angle formations, making them ideal for industries that demand precise and consistent angle bending.

Whether it’s creating angle profiles for architectural structures, manufacturing metal brackets, or producing components for automotive frames, angle bending machines provide the necessary capabilities to meet these requirements with ease.

Imprint Bending Machines

Imprint bending machines are versatile CNC bending solutions that cater to a wide range of applications. With their easy programming and control, these machines simplify the process of creating complex bends, allowing for greater design flexibility.

Whether it’s imprinting logos and patterns on metal sheets for decorative purposes or forming intricate shapes for artistic designs, imprint bending machines excel at providing precise and intricate bends with a high level of detail and accuracy.

| Key Features and Applications of CNC Bending Machines | |

|---|---|

| Angle Bending Machines | Imprint Bending Machines |

|

|

With their specialized capabilities, CNC bending machines for angle bending and imprint bending open up new avenues for creativity and precision in the fabrication of metal components.

CNC Bending Machine for Bending Prisms with Electronic Angle Measurement

A specialized CNC bending machine with electronic angle measurement is designed specifically for bending prisms. These machines offer exceptional accuracy, thanks to their electronic angular measurement capabilities and flattened bending bars. With their ability to deliver precise and consistent results, they are particularly popular for small batch productions and single-piece bending projects.

The glass industry extensively utilizes CNC bending machines for prism bending applications. These machines play a crucial role in shaping glass prisms with high precision for various uses. The advanced features and tools incorporated into these machines ensure the production of superior quality prisms.

The use of electronic angle measurement in CNC bending machines for prism bending enhances their accuracy and efficiency. By precisely measuring the angle, these machines can deliver bends with unparalleled precision, meeting the stringent requirements of the glass industry.

| Benefits | Applications |

|---|---|

|

|

Choosing the Right CNC Bending Machine

Investing in a CNC bending machine is a significant decision for any business. To ensure maximum productivity and high-quality results in your bending operations, it is crucial to select the right machine that suits your specific needs. There are several factors to consider when making this important choice.

Firstly, think about the intended applications of the CNC bending machine. What types of components and materials will you be working with? Different machines offer various features and capabilities, so it’s essential to choose one that can handle your specific requirements.

Next, consider the customization options that the CNC bending machine offers. Depending on your industry and workflow, you may need additional features or modifications to optimize your bending process. Look for a machine that can be tailored to your unique needs.

Finally, pay close attention to the reputation of the manufacturer. A well-established and reputable company like Accurl provides a range of CNC bending machines with different features to meet the diverse demands of various industries. Their machines are not only affordable but also eco-friendly, contributing to sustainable operations.

By selecting the right CNC bending machine, you can benefit from its advanced features, customization options, and cost-effective operation. It allows you to maximize productivity, achieve high-quality results, and gain a competitive edge in your industry.