A CNC machine is an automated machine that performs a variety of complex tasks, such as machining, welding, and cutting. It is designed to use computer-aided design (CAD) and computer-aided manufacturing (CAM) software to create custom parts and components. The CNC machine is typically operated by a computer program that can be programmed to execute specific tasks. CNC stands for “computer numerical control” and is a type of computer-controlled manufacturing process that uses a series of instructions to move and shape a variety of materials. The machine is operated through a series of commands that are entered into the system’s software. The instructions are then interpreted by the machine’s computer system and executed accordingly. The machine can be programmed with a variety of different instructions to create complex components.

CNC machines are widely used in the manufacturing industry due to their accuracy and repeatability. They are capable of creating components with precision and repeatability that would be difficult or impossible with manual tools. In addition, the use of CNC machines allows for a faster production process with fewer errors. CNC machines are also highly customizable, allowing manufacturers to create a variety of custom parts that can be produced quickly and with a high level of precision.

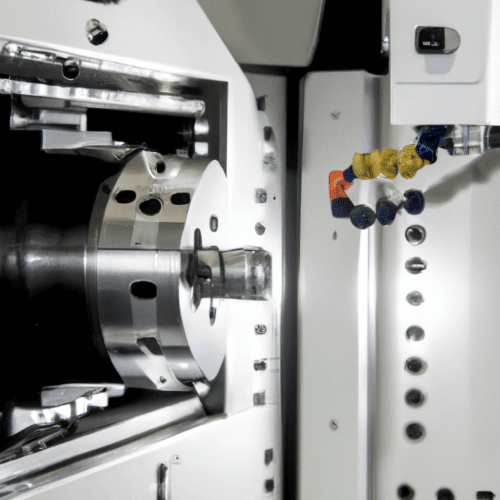

An Introduction to What a CNC Machine Is and How It Works

A CNC (Computer Numerical Control) machine is a type of automated tool used for manufacturing precision parts. It is a computerized machine that uses programmed instructions to control the motions of the machine, allowing it to produce parts with exact precision and repeatability. CNC machines are programmed with a specific set of instructions, which are then used to control the movement of the machine’s cutting tools. The instructions are typically written in a computer language called G-code. CNC machines are able to produce parts with very high levels of accuracy. They are able to create parts with extremely tight tolerances and repeatable results. This makes them ideal for manufacturing parts that require precise measurements and exact specifications. Additionally, CNC machines are able to work with a wide variety of materials, including metal, wood, plastics, and composites. The heart of a CNC machine is the controller. This is a computer system that is responsible for controlling the machine’s movements.

The controller is connected to the machine’s motors, which are responsible for controlling the movement of the cutting tools. The controller is also responsible for interpreting the instructions written in G-code and translating them into actual instructions for the motors. CNC machines are used in a variety of industries, from aerospace to automotive, and from medical to consumer goods. They are used for creating a wide range of products, from medical implants to aircraft parts. They are also used in the production of plastic parts, such as those used in 3D printing. CNC machines have replaced manual machines in many industries, as they are able to produce parts with higher precision and much faster than their manual counterparts. Additionally, CNC machines are capable of producing parts with much higher levels of complexity than manual machines can. CNC machines are able to produce parts with features that are impossible to create with manual machines. CNC machines are incredibly versatile and can be used to produce a wide variety of parts. They are capable of producing parts with extremely tight tolerances, as well as parts with complex shapes and features. CNC machines are also able to work with a wide variety of materials, including metal, wood, plastics, and composites.

Benefits of Using a CNC Machine

CNC machines are computer-controlled tools used to cut and shape a variety of materials including plastics, wood, and metal. These tools have revolutionized the manufacturing industry, providing increased precision, consistency, and savings in production costs. CNC machines offer a variety of benefits to those working in manufacturing, including increased efficiency, accuracy, and cost savings. The most prominent benefit of using a CNC machine is the increased efficiency it offers. CNC machines are programmed to perform a specific task, and can complete the job in a fraction of the time it would take a human operator. This increased efficiency leads to faster production times, which in turn leads to greater profitability. Additionally, CNC machines are capable of performing complex operations with precision and accuracy, eliminating errors and reducing waste. CNC machines also offer improved safety in the workplace. By eliminating the need for human operators to perform complex and potentially dangerous tasks, CNC machines reduce the risk of injury and improve the overall safety of the manufacturing environment.

Finally, CNC machines can provide significant cost savings to manufacturers. By increasing efficiency, accuracy, and safety, CNC machines reduce the need for additional staff or equipment, resulting in lower overhead costs. Additionally, CNC machines can produce components with extremely tight tolerances, eliminating the need for costly rework and scrap. Overall, CNC machines offer a variety of benefits for those working in manufacturing. By increasing efficiency, accuracy, safety, and cost savings, CNC machines can provide manufacturers with a competitive edge in the market.

Types of CNC Machines and Their Uses

CNC machines are computer numerical control devices used in a variety of industries to create precise, automated machining processes. These machines are incredibly versatile and can be used to create a variety of products, from intricate sculptures to complex manufacturing components. CNC machines come in a variety of types and sizes, each of which is designed for a specific purpose. The most common type of CNC machine is a milling machine. The milling machine is used to shape metal and other materials by cutting, drilling, and removing material. It is capable of creating complex shapes and patterns with a high degree of accuracy. It is often used to create parts for medical devices, automotive parts, and other industrial products. Lathes are another type of CNC machine. These machines can be used to create precision parts for products like watches, firearms, and other complex items. Lathes are typically used to shape metal, and they can be programmed to rotate at specific speeds to create the desired shape. Lathes are also commonly used in the production of musical instruments. Another type of CNC machine is the router.

Routers are used to cut out complex shapes from sheets of wood, plastic, and other materials. They can also be used to create complex patterns and designs on the surface of these materials. Routers are also used in the production of furniture and cabinets. CNC machines are also used in the production of printed circuit boards. These machines are programmed to etch patterns and create components on a circuit board. This technology is used to create sophisticated electronic devices, such as cell phones and computers. CNC machines are used in a variety of industries and applications, from automotive manufacturing to jewelry making. They are capable of producing complex products with precision and accuracy, and they are often used to reduce labor costs and increase efficiency. These machines are essential tools in the modern manufacturing process, and their use is becoming increasingly widespread.

Common CNC Machine Maintenance Tasks

CNC machines help to streamline the manufacturing process, but to ensure optimal performance, regular maintenance is necessary. Here are some common maintenance tasks for CNC machines:

1. Cleaning: Keeping the machine clean is essential for maintaining its optimal performance. Make sure to vacuum off the machine and wipe down the surfaces regularly.

2. Lubrication: Lubricating the moving components helps to reduce friction and wear. Check the lubrication levels and replenish as necessary.

3. Alignment: Ensure that the machine is properly aligned with its parts. Any misalignment can cause the machine to malfunction or cause damage.

4. Inspections: Periodically inspect the machine for any signs of wear or damage. Make sure to replace any worn or damaged parts as soon as possible.

5. Maintenance: Regular maintenance helps to keep the machine running smoothly. Make sure to perform routine maintenance tasks such as checking oil levels, replacing worn parts, and calibrating the machine. By completing these common maintenance tasks regularly, you can help to ensure that your CNC machine runs efficiently and reliably.

CNC Machining Innovations and How They Improve Efficiency

CNC machining is a process of cutting and shaping metal and other materials for production, prototyping, and repair. It has changed significantly over the years, and the advancements made in CNC machining technology have improved efficiency and accuracy in the production process. One of the main innovations in CNC machining is the use of Computer-Aided Design (CAD) software. This software allows for the accurate design of components in 3D space before they are ever made. It also allows for the precise creation of machining paths for CNC machines, which can reduce the amount of time needed to create a finished product. CAD software also increases the accuracy of CNC machining, as it can allow for greater precision in the machining paths. Another innovation in CNC machining is the use of more advanced cutting tools. This includes the use of diamond-tipped tools, which can allow for higher speeds and longer tool life. It also includes the use of end mills with extreme rake angles, which can reduce the amount of time needed for machining.

CNC machining has also seen advances in automation. Automation allows for CNC machines to run more efficiently, with fewer errors and more consistent results. Automated machines can be programmed to complete multiple processes without the need for manual intervention, allowing for faster production times and less downtime. In addition, CNC machines can now be programmed to communicate with other machines and systems. This allows for the integration of automated systems, which can improve the speed and accuracy of the production process. Finally, CNC machining has seen advancements in materials. New materials, such as composites, can be machined faster and with greater accuracy. This can lead to faster production times and improved quality of the finished product. These innovations in CNC machining have allowed for higher productivity and accuracy in the production process. This has allowed for faster production times, improved quality, and lower costs. As technology continues to advance, CNC machining will continue to become more efficient and accurate.