A CNC (Computer Numerical Control) milling machine is a type of machining tool that uses computer-controlled operations to shape and cut materials. It is a versatile tool that can be used to create a variety of shapes and sizes, from simple to complex. CNC milling machines are typically used in the manufacturing industry to create precision parts and components.

CNC milling machines are equipped with a variety of tools, including drills, end mills, and reamers. These tools are used to cut and shape the material into the desired shape. The CNC machine is programmed with a set of instructions that tell it how to move the tool and how deep to cut into the material. The CNC machine is then able to accurately and precisely cut the material into the desired shape.

CNC milling machines are used in a variety of industries, including aerospace, automotive, medical, and electronics. They are also used in the production of furniture, musical instruments, and other items. CNC milling machines are highly accurate and can produce complex shapes with a high degree of precision. They are also relatively easy to operate and maintain, making them a popular choice for many manufacturing applications.

What is a CNC milling machine and how does it work?

A CNC (Computer Numerical Control) milling machine is a type of machining tool that uses computer-controlled processes to shape and cut materials. It is typically used to create complex shapes and parts from a variety of materials, including metals, plastics, and composites. The CNC milling machine works by using a computer to control the movement of the cutting tool, which is usually a rotating cutting tool such as a drill bit, end mill, or router bit. The computer controls the movement of the cutting tool by sending instructions to a motor that is connected to the cutting tool. The motor then moves the cutting tool in the desired direction and at the desired speed.

The CNC milling machine is programmed with a series of instructions that tell it how to move the cutting tool in order to create the desired shape or part. The instructions are typically written in a computer language such as G-code or M-code.

What is CNC milling used for?

CNC (Computer Numerical Control) milling is a machining process that uses computer-controlled cutting tools to shape and fabricate parts from a variety of materials. It is a type of subtractive manufacturing process, where material is removed from a workpiece by a rotating cutting tool. CNC milling is used to create parts with complex shapes and features, such as slots, pockets, and contours. It is also used to create precision parts with tight tolerances. CNC milling is used in a variety of industries, including aerospace, automotive, medical, and electronics. It is used to create parts for aircraft engines, medical implants, and circuit boards. CNC milling is also used to create molds and dies for injection molding and die casting. CNC milling is a versatile process that can be used to create a wide range of parts with complex shapes and features. It is a cost-effective way to produce high-quality parts in a short amount of time.

What can CNC milling machines make?

CNC (Computer Numerical Control) milling machines are a type of automated machine tool that can be used to produce a wide variety of parts and components with high precision and accuracy. CNC milling machines are capable of producing a wide variety of shapes and sizes, from simple two-dimensional shapes to complex three-dimensional shapes. CNC milling machines can be used to produce a variety of components, including:

- Complex 3D shapes such as turbine blades, impellers, and other components used in aerospace and automotive industries.

- Complex 2D shapes such as gears, cams, and other components used in the manufacturing of machinery.

- Complex 3D shapes such as molds and dies used in the production of plastic and metal parts.

- Complex 2D shapes such as circuit boards and other components used in the electronics industry.

- Complex 3D shapes such as medical implants and prosthetics used in the medical industry.

- Complex 2D shapes such as signs and logos used in the advertising industry.

What is the difference between CNC and milling?

The primary difference between CNC (Computer Numerical Control) and milling is the level of automation. CNC is a fully automated process that uses computer-controlled machines to cut and shape materials, while milling is a manual process that uses a rotating cutting tool to shape materials.

CNC machines are programmed using a computer-aided design (CAD) software, which allows for precise control over the cutting process. The machine is programmed to move the cutting tool in a specific pattern, and the cutting tool is then used to cut the material. CNC machines are capable of producing complex shapes and intricate details with a high degree of accuracy.

Milling, on the other hand, is a manual process that requires the operator to manually move the cutting tool in order to shape the material. The operator must be skilled in order to produce accurate results, and the process is much slower than CNC.

What can CNC machines cut?

CNC (Computer Numerical Control) machines are automated machines that are used to cut and shape a variety of materials. They are used in a wide range of industries, from aerospace and automotive to medical and consumer products. CNC machines can cut a variety of materials, including metals, plastics, composites, wood, and foam. Depending on the type of CNC machine, the cutting tool can be a router, drill, laser, plasma, or waterjet.

CNC machines are used to cut metal parts for a variety of applications, including automotive, aerospace, and medical. They can cut a variety of metals, including aluminum, steel, stainless steel, brass, and titanium. CNC machines can also cut plastic parts for a variety of applications, including consumer products, medical devices, and automotive components.

CNC machines can also be used to cut wood and foam. CNC routers are used to cut wood for furniture, cabinetry, and other woodworking projects. CNC machines can also be used to cut foam for packaging, insulation, and other applications.

How does a milling machine work?

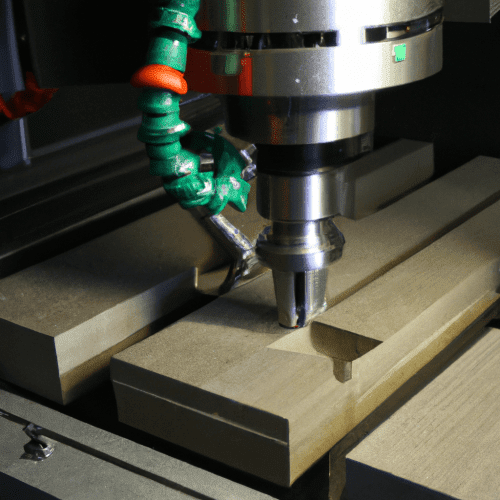

A milling machine is a tool used to shape and form solid materials such as metal and wood. It typically uses a rotating cutting tool to remove material from the workpiece in a variety of directions. The cutting tool can be moved in multiple directions and depths to create a variety of shapes and sizes.

The milling machine consists of a table, which is the workpiece, and a spindle, which is the cutting tool. The spindle is mounted on a motor that rotates the cutting tool at a high speed. The cutting tool is usually a drill bit, end mill, or router bit. The cutting tool is held in place by a collet, which is a type of chuck that holds the cutting tool in place.

The table is mounted on a bed, which is a platform that can be moved in the X, Y, and Z directions. The bed is moved by a leadscrew, which is a type of screw that is used to move the bed in a precise manner. The leadscrew is driven by a motor, which is usually a stepper motor.

What is CNC milling and turning?

CNC (Computer Numerical Control) milling and turning are two of the most common machining processes used in the manufacturing industry. CNC milling is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a workpiece in order to create a desired shape or geometry. CNC turning is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a rotating workpiece in order to create a desired shape or geometry.

CNC milling is typically used to create complex shapes and features in a workpiece, such as slots, pockets, and contours. The cutting tool is typically a rotating end mill that is moved in three axes (X, Y, and Z) to create the desired shape. The cutting tool is fed into the workpiece at a predetermined rate and depth, and the cutting tool is moved in a programmed pattern to create the desired shape.

What are the steps of the milling process?

Milling is a machining process that uses a rotating cutting tool to remove material from a workpiece. The milling process begins with the selection of the appropriate type of milling cutter for the material to be machined. The cutter is then mounted on the spindle of the milling machine and the workpiece is clamped in place.

The next step in the milling process is to set the cutting parameters, such as the feed rate, spindle speed, and depth of cut. The feed rate is the speed at which the cutter is moved across the workpiece, while the spindle speed is the rotational speed of the cutter. The depth of cut is the amount of material that is removed with each pass of the cutter.

Once the cutting parameters have been set, the milling process can begin. The cutter is moved across the workpiece in a series of passes, with each pass removing a small amount of material. The depth of each pass is determined by the depth of cut setting.

What is the process of milling?

Milling is a machining process that uses a rotating cutting tool to remove material from a workpiece. It is commonly used to create parts with complex shapes and features, such as slots, grooves, and contours. The process of milling begins with the selection of the appropriate cutting tool for the job. The cutting tool is then mounted in a spindle and positioned in the workpiece. The spindle is then rotated at a predetermined speed, and the cutting tool is fed into the workpiece at a predetermined rate. As the cutting tool moves through the workpiece, it removes material in the form of chips. The chips are then collected and disposed of. The process is repeated until the desired shape and size of the part is achieved. The process of milling can be used to create parts from a variety of materials, including metals, plastics, and composites.