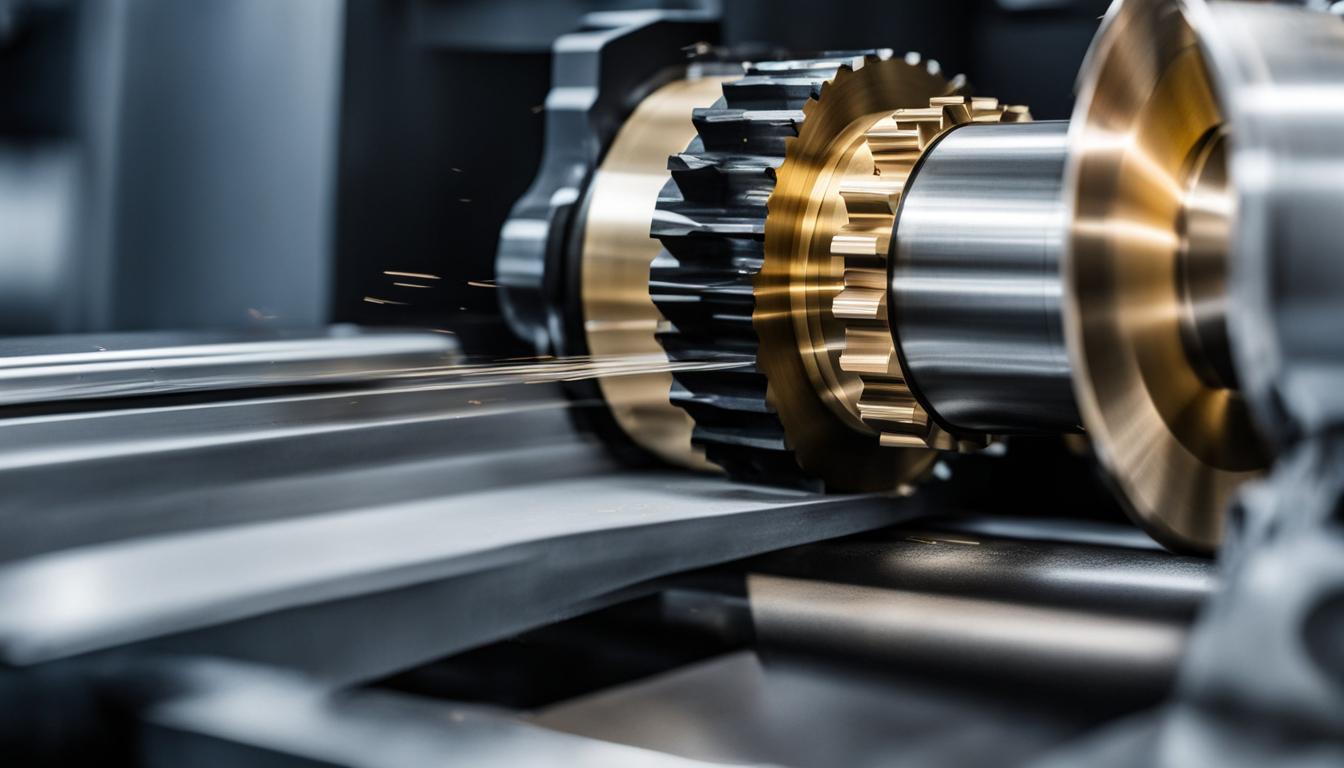

CNC turning services offer a widespread technology for manufacturing cylindrical parts from various materials. CNC turning is a subtractive manufacturing technology that involves rotating the workpiece while a tool moves to engage and remove material until the desired shape is achieved. Vertical and horizontal turning machines have different setups, with horizontal CNC turning being more common. CNC lathes and CNC turning centers have different capabilities, with turning centers being able to perform multiple operations. Turning machines consist of a spindle and chuck for holding the workpiece, and the cutting tools are mounted into tool holders. The crystal orientation of CNC turning tool inserts is important for tool life and performance.

Key Takeaways

- CNC turning machines are used to manufacture cylindrical parts.

- Vertical and horizontal turning machines have different setups.

- CNC lathes and CNC turning centers have different capabilities.

- Turning machines consist of a spindle, chuck, and tool holders.

- Crystal orientation affects the performance of CNC turning tool inserts.

What is CNC Turning?

CNC turning is a subtractive manufacturing process that involves removing material from a cylindrical stock piece using a rotating workpiece and a stationary tool. It is a widely used technology for manufacturing cylindrical parts from various materials. In addition to cylindrical shapes, CNC turning can also be performed on other stock shapes such as hex or square bars.

There are two types of CNC turning machines: vertical and horizontal. The choice between the two depends on factors like the size and weight of the design. Horizontal CNC turning machines are more common. CNC turning centers, on the other hand, are capable of multiple operations, while a lathe simply turns the workpiece.

How do CNC Turning Machines work?

CNC turning machines are a vital component in the manufacturing industry, effectively shaping cylindrical parts with precision and efficiency. Understanding the inner workings of these machines can provide valuable insights into their capabilities and applications.

The process of CNC turning involves the rotation of a workpiece while a cutting tool engages with it, gradually removing material to achieve the desired shape. To initiate this process, a CAD model of the part is created using computer-aided design software, which is then converted into a machine-readable format.

Upon preparation, the machine is set up by securing the workpiece in place and mounting the cutting tools. The lathe is then programmed using CNC software, providing the necessary instructions for the turning process.

During the turning process, the workpiece rotates at a specified speed and feed rate, while the cutting tool engages with the material, gradually shaping it according to the CAD model. To achieve a smooth surface finish, the cutting tool can be replaced with a finishing tool.

CNC turning centers are equipped with advanced features such as multiple turrets, enabling faster and more efficient operation. These machines have revolutionized the manufacturing industry by providing accurate and consistent results while reducing the risk of errors associated with manual turning machines.

Overall, CNC turning machines have proven themselves as essential tools in modern manufacturing, offering a precise and reliable solution for the production of cylindrical parts.

Types of CNC Turning Machines

CNC turning machines come in various types, each with its own advantages and applications. Understanding these different types can help manufacturers choose the right machine for their specific needs.

1. Horizontal Turning Centers

Horizontal turning centers have the spindle mounted parallel to the floor. This configuration allows for easy loading and unloading of workpieces. Horizontal turning centers are commonly used for producing a wide range of part sizes and shapes, making them versatile and suitable for various industries.

2. Vertical Turning Centers

Vertical turning centers feature a spindle placed in the vertical position. This design is particularly useful when machining workpieces on one side using rotating tools. Vertical turning centers offer stability and precision, making them ideal for applications that require high accuracy.

3. Horizontal Lathes

Horizontal lathes have a horizontal arbor and can produce parts of different sizes and shapes. They are commonly used for general turning operations and are favored for their simplicity and ease of use.

4. Vertical Lathes

Vertical lathes have a fixed spindle along the vertical plane. They are well-suited for machining large, heavy workpieces and are commonly used in industries such as aerospace and automotive. Vertical lathes provide excellent stability and can be equipped with multiple tooling stations for increased productivity.

Each type of CNC turning machine offers unique advantages, allowing manufacturers to choose the one that best suits their specific requirements. Whether it’s horizontal or vertical, turning centers or lathes, CNC turning machines are versatile tools in the world of precision machining.

Types of CNC Turning Operations

CNC turning machines are capable of performing various operations to create precise and intricate cylindrical parts. These operations include:

- Facing: Cutting a flat surface perpendicular to the rotational axis of the workpiece. This operation is useful for creating smooth and even surfaces.

- Turning: Removing material from the outer diameter of the workpiece to create a cylindrical or tapered shape. This operation is fundamental to CNC turning.

- Drilling: Making holes in the workpiece. CNC turning machines can accurately drill holes of different sizes and depths.

- Boring: Enlarging existing holes with precise accuracy. This operation is commonly used to achieve the desired dimensions of a hole.

- Threading: Cutting threads into a hole or over the outer diameter of the workpiece. This operation is essential for creating threaded parts.

- Grooving/Parting: Creating features like O-ring grooves on the workpiece or separating completed parts from the stock. This operation allows for increased functionality and efficiency.

- Knurling: Adding a diamond pattern to the surface of the workpiece to enhance grip and aesthetics. Knurling is commonly used on tools and handles.

The table below summarizes the different types of CNC turning operations and their purposes:

| Operation | Purpose |

|---|---|

| Facing | Create flat surfaces |

| Turning | Shape the outer diameter |

| Drilling | Create holes |

| Boring | Enlarge existing holes |

| Threading | Create threads |

| Grooving/Parting | Create features or separate parts |

| Knurling | Enhance grip and aesthetics |

Advantages of CNC Turning

CNC turning machines offer numerous advantages over manual turning machines. These benefits include:

1. Accuracy

CNC turning machines can reliably produce precise parts with automated control, ensuring consistent accuracy in every production run. The computerized programming eliminates the risk of human errors that can occur with manual turning machines. This precision is essential for meeting tight tolerances and maintaining the quality of the manufactured parts.

2. Flexibility

CNC turning allows for the production of a wide range of complex parts. The machines can work on various materials and create intricate designs with ease. Furthermore, turning centers with milling capabilities further enhance flexibility by offering the ability to perform additional operations, such as drilling and milling, in a single setup.

3. Safety

CNC turning machines prioritize safety with the inclusion of machine guards and protective measures. These features ensure the safety of operators and minimize the risk of accidents during the machining process. By reducing potential hazards, CNC turning machines provide a safer working environment.

4. Faster Results

CNC turning machines offer faster results compared to manual turning methods. The precise instructions programmed into the machines, along with quick tool-change capabilities, allow for efficient production. This speed is crucial for meeting tight deadlines and increasing overall productivity.

Overall, CNC turning machines provide manufacturers with the advantages of accuracy, flexibility, safety, and faster results. These benefits make CNC turning an essential tool in modern manufacturing processes.

Conclusion

CNC turning machines play a crucial role in modern manufacturing, offering precise and efficient solutions for producing cylindrical parts. With a deep understanding of CNC turning, manufacturers can harness the full potential of this technology to enhance their production capabilities. From understanding the process and operations to leveraging its advantages, CNC turning machines allow manufacturers to achieve high levels of precision and productivity.

As technology continues to advance, CNC turning machines are evolving to provide even more complex design options and faster operations. With the ability to produce intricate parts with automated control, CNC turning machines reduce the risk of errors, ensuring consistent quality. The flexibility of CNC turning allows for a wide range of part designs, while the combination of milling and turning capabilities in turning centers offers unparalleled versatility.

By embracing CNC turning, manufacturers can streamline their production processes, improve efficiency, and meet the demands of the ever-evolving market. With the precision and speed offered by CNC turning machines, manufacturers can gain a competitive edge, delivering high-quality cylindrical parts in a timely fashion. CNC turning is not just a technology; it’s a game-changer that empowers manufacturers to achieve excellence in their production operations.