CNC furniture is furniture that has been designed to be cut using a Computer Numeric Control (CNC) machine. CNC machines are computer-controlled cutting machines that can create very precise cuts in a variety of materials. CNC furniture is often designed to use minimal supplies and no fasteners, by using a series of components that fit together in tension and compression. This type of furniture can be very strong and durable, as well as being relatively easy to assemble. CNC furniture can be an excellent option for those who are looking for unique and high-quality furniture that is easy to assemble.

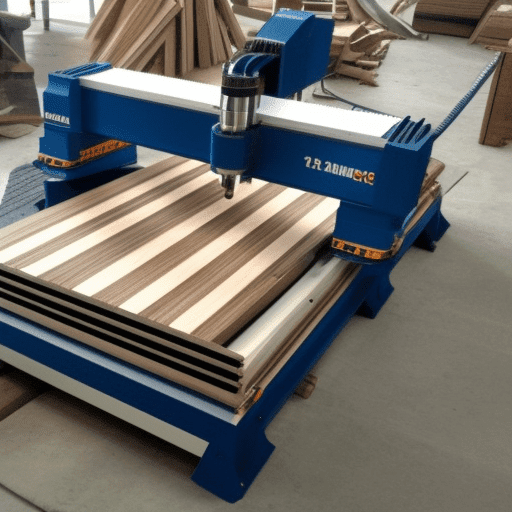

Making furniture with a CNC machine

Making furniture with a CNC machine is a great way to get the most out of your woodworking shop. With a CNC router from Laguna Tools, you can create almost anything out of wood in very little time. Whether you chose a Swift or a SmartShop machine, you can create almost anything out of wood in very little time. Making furniture with a CNC machine is not only convenient, but it’s also very precise. You can create whatever design you want, and you don’t have to worry about making mistakes. With a CNC machine, you can make any piece of furniture you can imagine, and you can do it quickly and easily. So if you’re looking for a way to take your woodworking to the next level, consider getting a CNC router from Laguna Tools. You won’t be disappointed.

How much does it cost to CNC wood?

The average CNC machining cost per hour for a 3-axis CNC machine is around $40. The operator salary of CNC milling machines can range from $30 to $50 per hour. Therefore, the total cost of CNC services, in this case, would be around $80 per hour. This does not include the price of the wood or any other materials that may be required for the project. In general, the cost of CNC machining is based on the time it takes to complete the project, the complexity of the design, and the number of axes required. For simple projects, the cost can be as low as $20 per hour, while more complex designs can cost over $100 per hour. When considering the cost of CNC machining, it is important to factor in the time required to set up and program the machine, as well as the time needed for finishing and assembly. With careful planning and budgeting, it is possible to get high-quality CNC machined parts at a reasonable price.

How thick of wood can a CNC cut through?

How thick of a piece of wood can a CNC machine cut through? This all depends on the bit that is being used. For thinner pieces of wood, or for cutting through materials like plastic, a quarter inch diameter bit is good. It can make precise cuts and remove material quickly. However, for thicker pieces of wood, you will need to use a bit with a larger diameter. The effective cutting depth for these bits is usually 1 inch. This will allow you to make deeper cuts and remove more material per pass. With the right bit, a CNC machine can easily cut through even the thickest pieces of wood.

Can you CNC solid wood?

As it turns out, you can! And the results are pretty stunning, too. All the characteristics of excellent wooden joints – including appearance, strength, and flexibility – can be enhanced on a CNC machine with the addition of accuracy and repeatability. That means that even the most intricate designs can be executed with precision, and then replicated over and over again with perfect consistency. Best of all, the entire process can be automated, so that once the initial design is created, the rest is simply a matter of pushing a button. If you’re looking for a way to take your woodworking to the next level, CNC machining is definitely worth considering.

What type of wood is best for CNC?

There are a few factors to consider when choosing the best wood for CNC work. Hardwoods like maple, walnut, cherry, and ash are good choices because they’re strong and durable. Cedar and cypress are good softwood options because they’re also strong and resistant to damage. The type of wood you choose will also depend on the type of project you’re working on. If you’re doing detailed work, you’ll want to choose a hardwood that’s easy to carve. If you’re working on a larger project, a softwood like cedar or cypress may be a better choice. No matter what type of wood you choose, make sure you use the right bit and feed and speed settings to get the best results.

How do I start a CNC woodworking business?

The first step is to purchase a CNC router. A CNC (computer numerical control) router is a machine that uses computer-controlled cuts to create intricate patterns in wood. Once you have your router, you’ll need to decide on your first project. This will be your prototype; it will help you perfect your technique and hone your skills. After you’ve completed your project, it’s time to come up with a business plan. This should include a description of your products, a marketing strategy, and a financial plan. Next, you’ll need to build an online store. There are many platforms that offer e-commerce services; choose the one that’s right for you. Once your store is up and running, it’s time to start marketing your products. You can use social media, online advertising, and PR campaigns to get the word out about your business. Finally, launch your store and start selling!