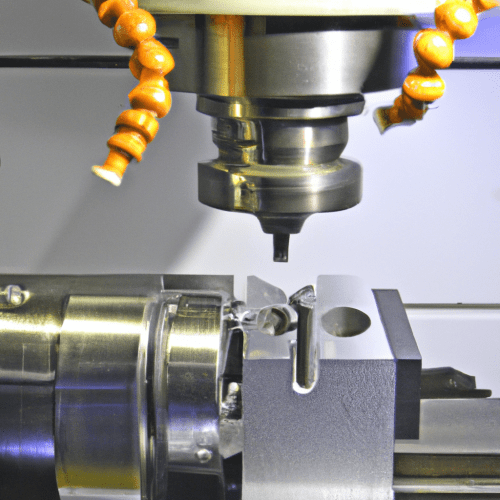

CNC machining is a manufacturing process that uses computer numerical control (CNC) machines to shape and cut materials into a desired shape or size. CNC machining is a subtractive manufacturing process, meaning that material is removed from a workpiece to create the desired shape or size. CNC machining is used to create parts for a wide range of industries, including aerospace, automotive, medical, and consumer products.

CNC machining is a highly automated process that uses computer-controlled machines to shape and cut materials. The machines are programmed with a set of instructions that tell them how to move and shape the material. The instructions are written in a computer language called G-code, which is a language specifically designed for CNC machines. The G-code instructions tell the machine how to move the cutting tool, how fast to move it, and how deep to cut into the material.

CNC machining is a versatile process that can be used to create a wide variety of parts and components. It is used to create parts for a variety of industries, including aerospace, automotive, medical, and consumer products. CNC machining is also used to create custom parts for prototyping and production.

CNC machining is a precise process that produces parts with tight tolerances and high accuracy. The machines are capable of producing parts with complex geometries and intricate details. CNC machining is also a cost-effective process, as it requires minimal setup time and can produce parts in large quantities.

What is CNC machine in simple words?

A CNC (Computer Numerical Control) machine is a type of automated machine tool that uses computer programs to control the movement and operation of the machine. It is used to produce high-precision parts with complex shapes. CNC machines are typically used in the manufacturing industry to create parts for a variety of products, such as cars, airplanes, and medical equipment. The machine is programmed with a set of instructions that tell it how to move and operate in order to create the desired part. The instructions are typically written in a computer language such as G-code or CNC programming language. CNC machines are highly accurate and can produce parts with very tight tolerances. They are also very efficient, as they can produce parts quickly and with minimal waste.

Where CNC machines are used?

Computer Numerical Control (CNC) machines are automated machines that are used to perform a variety of tasks with precision and accuracy. They are used in a wide range of industries, including manufacturing, automotive, aerospace, medical, and electronics. CNC machines are used to cut, shape, and form materials such as metal, wood, plastic, and composites. They can also be used to drill, mill, and engrave parts.

CNC machines are used in the manufacturing industry to produce parts for a variety of products. They are used to cut and shape metal, wood, plastic, and composites into the desired shape and size. CNC machines are also used to drill, mill, and engrave parts. CNC machines are used in the automotive industry to produce parts for cars, trucks, and other vehicles. They are used to cut and shape metal, plastic, and composites into the desired shape and size.

What is CNC and how it works?

CNC stands for Computer Numerical Control, and it is a type of automation technology used in the manufacturing industry. It is a process that uses computer-controlled machines to perform a variety of tasks, such as cutting, drilling, and milling. CNC machines are programmed with a set of instructions that tell the machine what to do and how to do it.

The CNC process begins with the creation of a computer-aided design (CAD) file. This file contains the instructions for the CNC machine, including the type of material to be used, the size and shape of the part, and the exact dimensions of the part. Once the CAD file is created, it is sent to the CNC machine, which reads the instructions and begins to cut, drill, or mill the material according to the instructions.

Why CNC machines are used?

Computer Numerical Control (CNC) machines are automated machines used in manufacturing processes that are programmed to perform specific tasks. CNC machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products. CNC machines are used to produce parts with high precision and accuracy, as well as to reduce production costs and time.

CNC machines are used because they are able to produce parts with a high degree of accuracy and repeatability. CNC machines are programmed with a set of instructions that tell the machine how to move and what operations to perform. This allows for the production of parts with a high degree of precision and accuracy. CNC machines are also able to produce parts with a high degree of repeatability, meaning that the same part can be produced multiple times with the same results.

CNC machines are also used because they are able to reduce production costs and time. CNC machines are able to produce parts quickly and efficiently, which reduces the amount of time and money spent on production.

What is CNC machine introduction?

A CNC (Computer Numerical Control) machine is a type of automated machine tool that uses computer programs to control the movement and operation of the machine. CNC machines are used to produce high-precision parts with complex shapes in a wide variety of materials. CNC machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products.

CNC machines are typically composed of three main components: the controller, the machine tool, and the cutting tool. The controller is the computer that runs the CNC program and controls the machine tool. The machine tool is the physical machine that moves the cutting tool and produces the part. The cutting tool is the tool that actually cuts the material.

CNC machines are programmed using a computer-aided design (CAD) program. The CAD program is used to create a 3D model of the part that is to be produced. The 3D model is then converted into a CNC program, which is then loaded into the controller.