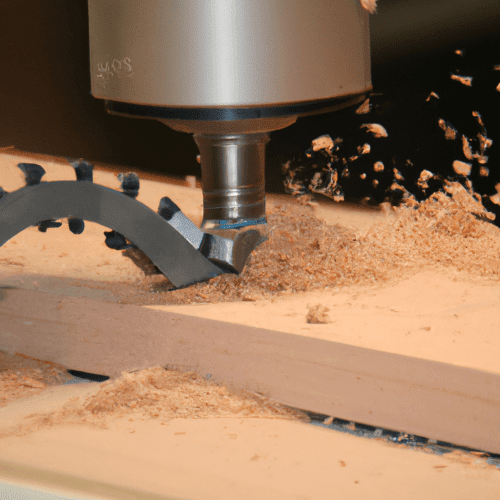

CNC woodworking is a form of woodworking that uses computer numerical control (CNC) machines to create intricate designs and shapes in wood. CNC machines are computer-controlled tools that use a variety of cutting tools to cut and shape wood into a desired shape. CNC woodworking is a great way to create complex and intricate designs in wood that would otherwise be difficult or impossible to create by hand. CNC machines can be used to create furniture, cabinetry, sculptures, and other woodworking projects. CNC machines are also used to create molds and templates for woodworking projects.

CNC woodworking is a great way to create precise and accurate designs in wood. CNC machines are programmed with a set of instructions that tell the machine how to cut and shape the wood. The instructions can be programmed into the machine using a computer program or manually entered into the machine. CNC machines are capable of cutting and shaping wood with a high degree of accuracy and precision.

What is a CNC for woodworking?

A CNC (Computer Numerical Control) machine is a type of automated machine tool that uses computer-controlled processes to cut and shape wood. It is used in woodworking to create precise, intricate, and complex shapes and designs. CNC machines are used to cut, shape, and finish wood products such as furniture, cabinets, doors, windows, and other wood products.

CNC machines are programmed with a computer-aided design (CAD) software program. The CAD software is used to create a 3D model of the desired product. The CNC machine then reads the 3D model and uses it to guide the cutting and shaping of the wood. The CNC machine is programmed to move the cutting tool along the 3D model, cutting and shaping the wood as it moves.

CNC machines are highly accurate and can produce complex shapes and designs with a high degree of precision. They are also very efficient, as they can produce multiple pieces of the same product in a short amount of time.

What wood can a CNC cut?

A CNC (Computer Numerical Control) machine is a type of automated machine tool that is capable of cutting a wide variety of materials. The type of wood that a CNC can cut depends on the type of CNC machine and the type of cutting tool used. Generally, CNC machines are capable of cutting softwoods, hardwoods, plywood, and particle board. Softwoods, such as pine, fir, and cedar, are relatively easy to cut with a CNC machine and require less power than hardwoods. Hardwoods, such as oak, maple, and walnut, are more difficult to cut and require more power. Plywood and particle board are also relatively easy to cut with a CNC machine, but the cutting tool must be sharp and the feed rate must be adjusted to prevent the cutting tool from becoming dull. Additionally, some CNC machines are capable of cutting non-wood materials, such as plastics, aluminum, and steel.

What does the CNC do?

CNC stands for Computer Numerical Control, and it is a type of automation used in the manufacturing industry. It is a process that uses computer-controlled machines to perform a variety of tasks, such as cutting, drilling, and milling. CNC machines are programmed with a set of instructions that tell the machine what to do and how to do it. The instructions are written in a computer language called G-code, which is a language specifically designed for CNC machines.

CNC machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products. They are used to create parts and components for a variety of products, from cars to medical devices. CNC machines are also used to create molds and dies for injection molding and die casting.

CNC machines are highly accurate and can produce parts with very tight tolerances. They are also very efficient, as they can produce parts quickly and with minimal waste. CNC machines are also very versatile, as they can be programmed to perform a variety of tasks.

What does CNC mean?

CNC stands for Computer Numerical Control, and it is a type of automation used in the manufacturing industry. It is a process in which a computer is used to control the movement of tools and machinery in order to create a product. CNC machines are programmed with a set of instructions that tell the machine what to do and how to do it. The instructions are usually written in a computer language such as G-code or CNC programming language. CNC machines are used to create a variety of products, from simple parts to complex components. They are used in a variety of industries, including aerospace, automotive, medical, and consumer products. CNC machines are highly accurate and can produce parts with a high degree of precision. They are also capable of producing parts with complex shapes and intricate details. CNC machines are used in a variety of manufacturing processes, including milling, drilling, turning, and grinding.

What are the disadvantages of a CNC router?

A CNC router is a computer-controlled cutting machine used to cut a variety of materials, such as wood, plastic, and metal. While CNC routers offer a number of advantages, such as increased accuracy and repeatability, they also have some disadvantages.

One of the main disadvantages of CNC routers is their cost. CNC routers are typically more expensive than manual routers, and the cost of the machine can be prohibitive for some businesses. Additionally, CNC routers require a significant amount of maintenance and upkeep, which can add to the cost of ownership.

Another disadvantage of CNC routers is that they require a significant amount of setup time. Setting up a CNC router can be a time-consuming process, and it requires a certain level of expertise. Additionally, CNC routers require a certain level of programming knowledge in order to operate them.

Finally, CNC routers are limited in terms of the materials they can cut. While CNC routers can cut a variety of materials, they are limited in terms of the thickness and type of material they can cut.

What is the meaning of CNC cutting?

CNC (Computer Numerical Control) cutting is a manufacturing process that uses computer-controlled cutting tools to shape and cut materials into specific shapes and sizes. It is a form of subtractive manufacturing, which is the opposite of additive manufacturing, which is the process of adding material to create a desired shape. CNC cutting is used in a variety of industries, including aerospace, automotive, medical, and consumer products.

CNC cutting is a highly precise process that is used to create complex shapes and intricate details. It is often used to create parts for machines, tools, and other products. The process involves a computer-controlled cutting tool, such as a router, drill, or laser, that is programmed to cut the material into the desired shape. The cutting tool is guided by a computer program that is programmed with the exact specifications of the desired shape. The cutting tool is then moved along the material, cutting it into the desired shape.

What is a CNC engraver?

A CNC engraver is a computer-controlled machine that uses a cutting tool to engrave or carve a design into a material. It is a type of Computer Numerical Control (CNC) machine, which is a computer-controlled device that uses a cutting tool to create a design on a material. CNC engravers are used in a variety of industries, including woodworking, metalworking, and plastics.

CNC engravers use a variety of cutting tools, such as end mills, routers, and lasers, to create a design on a material. The cutting tool is connected to a computer, which is programmed with a set of instructions that tell the machine how to move the cutting tool. The instructions are usually written in a computer-aided design (CAD) program. The cutting tool is then moved along the material in a precise manner, creating the desired design.