Metal stamping is a manufacturing process in which metal parts are formed by applying pressure to a sheet of metal. It is a process that is used to create a variety of components for a variety of industries, including automotive, aerospace, medical, and electronics. The process involves the use of a die and a press to shape the metal into the desired shape. The die is a hardened tool that is designed to cut and shape the metal into the desired shape. The press is used to apply the force necessary to shape the metal.

The metal stamping process begins with the selection of the metal to be used. The metal is then cut into the desired shape and size. The metal is then placed into the die and the press is used to apply the necessary force to shape the metal. The metal is then removed from the die and the finished product is inspected for quality.

The metal stamping process is used to create a variety of components, including brackets, clips, fasteners, and other components. It is also used to create components for a variety of industries, including automotive, aerospace and medical.

What is metal stamping used to make?

Metal stamping is a process used to form metal parts from a sheet of metal. It is a versatile and cost-effective method of producing parts in large quantities. The process involves placing a sheet of metal into a stamping press, which uses a tool and die to shape the metal into the desired shape. The press applies pressure to the metal, which is then cut, bent, or formed into the desired shape. The process can be used to create a variety of parts, including brackets, clips, fasteners, and other components. Metal stamping is used in a variety of industries, including automotive, aerospace, medical, and electronics. It is also used to create coins and medals. Metal stamping is a cost-effective way to produce parts in large quantities, and it is often used to create parts with complex shapes. It is also a fast and efficient process, which makes it ideal for mass production.

What is the meaning metal stamping?

Metal stamping is a process used to form metal parts from a sheet of metal. It is a cost-effective way to produce high-volume parts with tight tolerances. The process involves placing a sheet of metal into a stamping press, which uses a tool and die to shape the metal into the desired shape. The press applies pressure to the metal, which is then cut, bent, or formed into the desired shape. The process can be used to create a variety of parts, including brackets, clips, fasteners, and other components. Metal stamping is a versatile process that can be used to create parts with complex shapes and intricate details. It is also a cost-effective way to produce high-volume parts with tight tolerances.

What are the four type of metal stamping?

Metal stamping is a process used to shape and form metal parts by applying pressure to a sheet or strip of metal. It is a versatile and cost-effective way to produce a wide range of components for a variety of industries. There are four main types of metal stamping: blanking, piercing, forming, and drawing.

Blanking is a process used to cut out a desired shape from a sheet of metal. It is used to create parts such as washers, spacers, and gaskets. The metal is placed between two dies and a punch is used to cut out the desired shape.

Piercing is a process used to create holes in a sheet of metal. It is used to create parts such as rivets, screws, and bolts. The metal is placed between two dies and a punch is used to create the desired hole.

Forming is a process used to shape a sheet of metal into a desired shape. It is used to create parts such as brackets, clips, and hinges.

What is the process of stamping called?

The process of stamping is a metalworking technique that involves the use of a stamping press to shape and form metal into a desired shape. The process begins with the selection of the metal to be stamped, which is then cut to the desired size and shape. The metal is then placed in the stamping press, which is a machine that uses a combination of pressure and heat to shape the metal. The press applies pressure to the metal, which causes it to deform and take on the desired shape. The metal is then cooled and removed from the press. Depending on the application, the metal may then be further processed, such as through heat treatment, plating, or painting. The process of stamping is used in a variety of industries, including automotive, aerospace, and medical, and is used to create a wide range of products, from car parts to medical implants.

Why is metal stamping good?

Metal stamping is a popular manufacturing process that is used to create a variety of parts and components from a variety of metals. It is a cost-effective and efficient way to produce parts with a high degree of accuracy and repeatability. Metal stamping is a versatile process that can be used to create a wide range of shapes and sizes, from small components to large parts. It is also a fast process, with some parts being able to be produced in as little as a few seconds.

Metal stamping is a great choice for many applications because it is a cost-effective and efficient way to produce parts with a high degree of accuracy and repeatability. It is also a fast process, with some parts being able to be produced in as little as a few seconds. Additionally, metal stamping is a versatile process that can be used to create a wide range of shapes and sizes, from small components to large parts. It is also a relatively simple process that can be used to create complex parts with intricate details.

What is a stamping press used for?

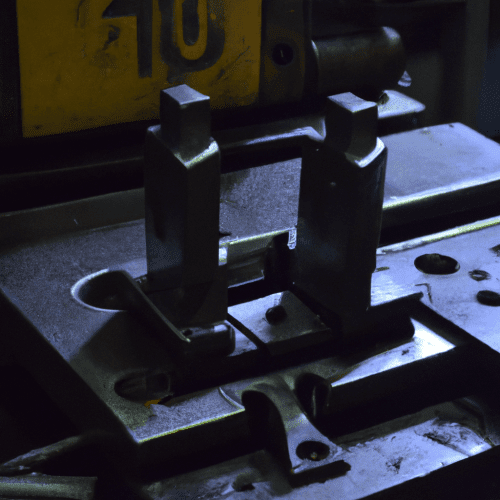

A stamping press is a type of machine press used to shape or cut metal by deforming it with a die. It can be used to cut, form, or shape a wide variety of materials, including sheet metal, wire, and thicker plates of metal. Stamping presses are used in a variety of industries, including automotive, aerospace, medical, and electronics.

Stamping presses are used to create a variety of parts, including brackets, clips, fasteners, and other components. They can also be used to create complex shapes, such as those found in automotive and aerospace parts. The press can be used to create parts with a variety of shapes, sizes, and thicknesses.

Stamping presses are typically powered by hydraulic or pneumatic systems, and they can be operated manually or automatically. The press can be used to create parts with a variety of shapes, sizes, and thicknesses. The press can also be used to create parts with a variety of finishes, such as anodized, painted, or plated.

What is metal stamping jewelry?

Metal stamping jewelry is a type of jewelry that is created by using a metal stamping process. This process involves using a metal stamping machine to create a design or pattern on a piece of metal. The metal is then cut, shaped, and polished to create a finished piece of jewelry. Metal stamping jewelry can be made from a variety of metals, including gold, silver, copper, brass, and aluminum. The metal is usually stamped with a design or pattern, such as a name, initials, or a logo. The design is then filled with enamel or paint to create a unique look. Metal stamping jewelry is often used to create personalized pieces of jewelry, such as rings, necklaces, and bracelets. It is also used to create charms, pendants, and other decorative pieces. Metal stamping jewelry is a popular choice for those looking for a unique and personalized piece of jewelry. It is also a great way to add a personal touch to a gift or to commemorate a special occasion.

When was metal stamping invented?

Metal stamping is a process that has been used for centuries to shape and form metal into a variety of shapes and sizes. The earliest known use of metal stamping dates back to the ancient Egyptians, who used a hammer and anvil to shape copper and bronze into tools and weapons. Metal stamping was also used by the ancient Greeks and Romans to create coins and jewelry.

The modern metal stamping process was developed in the late 1700s and early 1800s. This process involved the use of a press to shape metal into a desired shape. The press was operated by a hand crank and used a die to shape the metal. This process was used to create coins, jewelry, and other items.

In the late 1800s, the invention of the steam engine allowed for the development of the power press. This press was powered by steam and allowed for the production of larger and more complex parts. This process was used to create a variety of items, including car parts, tools, and other items.

What is stamping in car manufacturing?

Stamping in car manufacturing is the process of using a die to shape a sheet of metal into a desired shape. This process is used to create car body parts such as doors, hoods, and fenders. The metal sheet is placed between two dies, and then a press is used to apply pressure to the sheet, forcing it to take the shape of the die. This process is used to create parts with a high degree of accuracy and repeatability. The dies used in stamping are typically made from hardened steel and can be used to create complex shapes. The process is also used to create parts with a variety of textures and finishes. Stamping is a cost-effective way to produce large quantities of parts with a high degree of accuracy and repeatability.