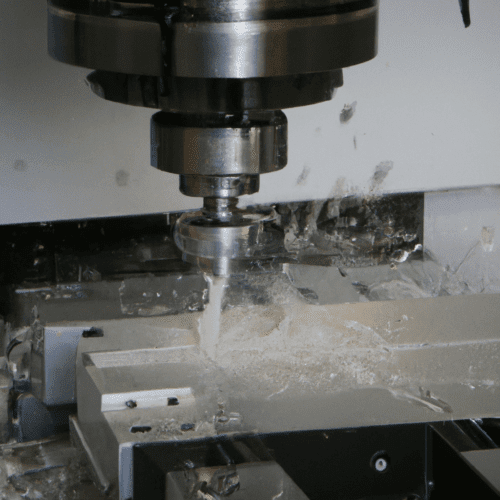

CNC (Computer Numerical Control) milling is a process that is automated by computers and uses computer-programmed commands to cut and shape metal or other materials. CNC milling machines use precision tools to cut and shape metals and other materials with great precision and accuracy. This process is much more efficient than conventional milling, which is done manually and requires greater skill and experience. CNC milling machines use tools that are controlled by computers and motors to move the cutting tool on three axes. This allows for greater accuracy and precision than conventional milling machines. CNC machines also have the capability to repeat the same cutting process over and over again with little to no variation in the end result.

This makes CNC milling an ideal process for creating detailed parts with very tight tolerances. Conventional milling machines, on the other hand, are operated manually by an individual using a hand-held tool. This process is slower and less precise than CNC milling and requires more skill and experience. It is mostly used for basic industrial operations such as cutting and shaping large pieces of metal or wood. Conventional milling machines are also capable of making complex parts but it requires more time and effort to produce the desired result.

Exploring the Advantages of CNC Milling Machines Compared to Conventional Milling Machines

CNC milling machines offer a range of advantages over conventional milling machines. For starters, CNC milling machines are automated, meaning they can be programmed to perform a number of complex operations with a single command. This allows for greater precision and accuracy in manufacturing, as well as a higher degree of consistency from one product to the next. Another advantage of CNC milling machines is their ability to produce a wider variety of shapes and sizes than conventional milling machines. CNC milling machines are capable of producing intricate, detailed designs with a high level of precision. This allows for a greater range of product customization, allowing manufacturers to meet the unique needs of their customers.

CNC milling machines are also more efficient than conventional milling machines. Since the machines are automated, they can complete tasks quickly and with a higher level of accuracy. This means that manufacturers can produce parts more quickly and with less waste. Finally, CNC milling machines are more cost-effective than conventional milling machines. CNC milling machines require less labor, as they are automated, and can be operated by a single operator. This reduces costs associated with hiring additional labor, as well as the cost of training new employees. Additionally, CNC milling machines require less maintenance than conventional milling machines, further reducing costs. Overall, CNC milling machines offer a number of advantages over conventional milling machines. From greater accuracy and faster production to cost savings, CNC milling machines are quickly becoming the preferred choice for many manufacturers.

Comparing CNC Milling Machines vs Conventional Milling Machines: The Pros and Cons

CNC (Computer Numerical Control) milling machines and conventional milling machines are both used to create parts from metal or other materials. CNC milling machines are precision-controlled and can produce intricate designs, while conventional milling machines are typically easier to operate and maintain. Before deciding which type of milling machine is best for a given project, it’s important to understand the pros and cons of each. The biggest advantage of CNC milling machines is the high degree of accuracy and precision they can achieve. These machines have the capability to make complex shapes and intricate designs with a high level of repeatability and accuracy. They are also able to produce parts with a very high degree of consistency, which is essential for many industries. CNC machines can also be programmed to create multiple parts at once, making them a great choice for mass production. The main disadvantage of CNC milling machines is the cost. They require a significant upfront investment and the software required to operate them can be expensive.

In addition, these machines require more maintenance than conventional milling machines, and they can be difficult to repair if something goes wrong. Conventional milling machines are much cheaper than CNC machines and can be used to produce basic parts. They are also relatively easy to operate and maintain, and parts can be created quickly and easily. However, they are not as precise as CNC machines and their accuracy is limited. Also, they require more manual labor to produce parts, as the entire process must be done by hand. In conclusion, when looking for a milling machine, it is important to consider the size of the project and the complexity of the parts being created. CNC milling machines offer a high degree of accuracy and precision, but come at a high cost. Conventional milling machines are cheaper and easier to operate, but they are not as precise and require more manual labor. Ultimately, it’s important to weigh the pros and cons of each type of machine to determine which is best for a given project.

Understanding the Difference between CNC and Conventional Milling Machines

CNC (Computer Numerical Control) and conventional milling machines are both used for cutting materials, but they have some key differences. CNC milling machines are automated and are controlled by a computer program. They use a variety of cutting tools to create complex shapes and can be programmed to produce specific shapes or parts. CNC machines are more accurate than conventional machines since they are controlled by a computer and have fewer chances of human error. Conventional milling machines, on the other hand, are manually operated. They are typically used for basic operations such as drilling or slotting. These machines are less accurate than CNC machines because they rely on the skill of the operator to control the movements of the cutting tool. In terms of speed, CNC machines are generally faster than conventional machines.

This is because the computer program can be programmed to move the cutting tool more quickly, and the operator does not have to manually adjust the tool’s speed. The cost of CNC machines is generally higher than that of conventional machines. This is because of the automated nature of the CNC machine and the cost of the computer program. Overall, CNC machines are more accurate, faster, and more expensive than conventional machines. They are ideal for larger or more complex projects that require precise results. Conventional machines, on the other hand, are more cost-effective and are ideal for basic operations and smaller projects.

What Are the Benefits of CNC Milling Machines Compared to Conventional Milling Machines?

CNC (Computer Numerical Control) milling machines have become increasingly popular among manufacturers in recent years due to their accuracy, speed, and efficiency. Compared to conventional milling machines, CNC milling machines offer numerous advantages. The most significant benefit of CNC milling machines is their accuracy. CNC machines are able to produce a much higher level of precision than manual milling machines. This is mainly due to the fact that CNC machines are automated and programmed with precise instructions. Additionally, CNC machines are typically more accurate than manual machines, even when operated by experienced professionals. This allows for greater precision when machining delicate parts or components. CNC milling machines are also faster than conventional machines. CNC machines are equipped with motors that are capable of much higher speeds than manual machines. This allows for faster production times and increased output. Additionally, CNC machines are capable of producing complex parts with multiple operations, which would be difficult or impossible to achieve with a manual machine.

Finally, CNC milling machines are more efficient than manual machines. CNC machines are equipped with powerful computers that can store and recall multiple programs. This allows for quick and efficient production cycles, as well as the ability to produce a wide variety of parts in a short amount of time. Additionally, CNC machines are equipped with automatic tool changing, which eliminates the need to manually change tools during production. This further increases the efficiency of CNC machines. Overall, CNC milling machines offer a variety of advantages over conventional milling machines, including greater accuracy, speed, and efficiency. CNC machines are ideal for high-precision parts and components, and can significantly improve production times and costs.

Exploring the Different Capabilities of CNC and Conventional Milling Machines

CNC (Computer Numerical Control) and conventional milling machines are both used in manufacturing for cutting and shaping materials. While both machines are used for the same purpose, they have different capabilities, and understanding the differences between them can help to determine which is best suited for a specific application. CNC milling machines are highly precise and automated machines that are programmed via a computer. They can be programmed to cut complex shapes with accuracy and repeatability. They are ideal for producing large, complex parts with a high level of accuracy and can be used to produce parts with a very high degree of precision. Additionally, CNC milling machines can produce intricate shapes due to their ability to move the cutting tool in multiple axes. Conventional milling machines are manual machines that are operated by hand. They are not as precise as CNC machines, and are often used to cut simpler shapes, such as straight lines and circles. They are ideal for producing parts with less complex shapes, but do not have the accuracy or repeatability of CNC milling machines.

Additionally, conventional milling machines cannot move the cutting tool in more than one axis, so more complex shapes cannot be created. In conclusion, CNC and conventional milling machines are both used in manufacturing, but have different capabilities. CNC milling machines are highly precise and capable of cutting complex shapes with accuracy and repeatability, while conventional milling machines are ideal for simpler shapes, but lack the accuracy and precision of CNC machines. Understanding the differences between the two can help to determine which is best suited for a specific application.