A high cutting speed is important in machining operations because it helps to reduce the amount of time it takes to complete a job. It also helps to reduce the amount of heat generated during the cutting process, which can cause tool wear and reduce the quality of the finished product. Additionally, a high cutting speed can help to reduce the amount of vibration that is generated during the cutting process, which can help to improve the accuracy and precision of the finished product. Finally, a high cutting speed can help to reduce the amount of power that is required to complete the job, which can help to reduce the cost of the operation.

Why is cutting speed important?

Cutting speed is an important factor in machining operations because it directly affects the quality of the finished product. The speed at which a cutting tool moves through a material affects the amount of heat generated, the amount of material removed, and the surface finish of the part. If the cutting speed is too slow, the cutting tool will generate too much heat, which can cause the material to deform or even melt. If the cutting speed is too fast, the cutting tool may not be able to remove enough material, resulting in an uneven surface finish. Additionally, the cutting speed affects the tool life of the cutting tool, as faster speeds can cause the tool to wear out more quickly. Therefore, it is important to select the correct cutting speed for a given material and machining operation in order to achieve the desired results.

What are the advantages of high speed machining?

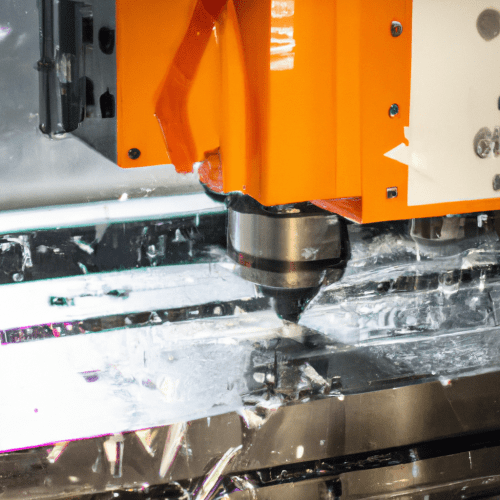

High speed machining (HSM) is a process that uses specialized tools and techniques to increase the speed and accuracy of machining operations. It is a form of computer numerical control (CNC) machining that uses high-speed spindles and high-speed cutting tools to achieve faster cutting speeds and higher accuracy than traditional machining methods. HSM is used in a variety of industries, including aerospace, automotive, medical, and electronics.

The primary advantage of high speed machining is its ability to produce parts with greater accuracy and precision than traditional machining methods. HSM is able to achieve higher cutting speeds and more accurate cuts due to the use of high-speed spindles and cutting tools. This allows for more precise cuts and a higher level of accuracy in the finished product. Additionally, HSM is able to produce parts with a higher level of surface finish than traditional machining methods. This is due to the fact that the high-speed spindles and cutting tools are able to produce smoother cuts and a more consistent surface finish.

What does cutting speed affect?

Cutting speed affects the rate at which material is removed from a workpiece during a machining operation. It is one of the most important factors in determining the quality of the finished product. The cutting speed affects the amount of heat generated during the cutting process, which in turn affects the surface finish of the workpiece. It also affects the tool life, as higher cutting speeds can cause the tool to wear out faster. Additionally, cutting speed affects the feed rate, which is the rate at which the cutting tool moves across the workpiece. The feed rate affects the depth of cut, which is the amount of material removed in a single pass. Finally, cutting speed affects the cutting forces, which can cause vibration and chatter, resulting in poor surface finish and accuracy.

What does cutting speed indicate?

Cutting speed is a term used in machining and manufacturing that refers to the speed at which a cutting tool, such as a drill bit, milling cutter, or lathe tool, moves through the material being cut. It is usually measured in units of distance per unit of time, such as meters per minute (m/min) or feet per minute (ft/min). Cutting speed is an important factor in machining operations, as it affects the quality of the finished product, the amount of time it takes to complete the operation, and the amount of wear and tear on the cutting tool.

The cutting speed of a tool is determined by the material being cut, the type of cutting tool being used, and the cutting conditions, such as the feed rate, depth of cut, and cutting fluid. The cutting speed of a tool is usually determined by the manufacturer and is listed in the tool’s specifications. The cutting speed of a tool can also be determined experimentally by running a series of tests and measuring the time it takes to cut a given material.

What happens if the cutting speed is too high?

If the cutting speed is too high, it can cause a variety of problems. The most common issue is that the cutting tool will wear out more quickly, leading to a shorter tool life. This can be caused by the cutting tool overheating, which can lead to a decrease in the cutting tool’s hardness and strength. Additionally, the cutting tool may not be able to cut the material properly, leading to poor surface finish and inaccurate cuts. Furthermore, the cutting tool may vibrate excessively, leading to chatter marks on the workpiece. This can also cause the cutting tool to break, which can be dangerous. Finally, the cutting speed may be too high for the machine to handle, leading to a decrease in the machine’s accuracy and precision.

In order to avoid these issues, it is important to select the correct cutting speed for the material and the cutting tool. The cutting speed should be based on the material’s hardness, the cutting tool’s material, and the machine’s capabilities.

When the cutting speed increases the power requirement?

When the cutting speed of a machine increases, the power requirement also increases. This is because the machine needs more energy to move the cutting tool faster. The power requirement is determined by the amount of force needed to move the cutting tool, and the speed at which the tool is moving. As the speed increases, the force required to move the tool also increases, and thus the power requirement increases.

The power requirement is also affected by the type of material being cut. Harder materials require more power to cut than softer materials. This is because harder materials require more force to move the cutting tool, and thus more power is needed.

The power requirement is also affected by the type of cutting tool being used. Different cutting tools require different amounts of power to move them. For example, a drill bit requires more power than a saw blade.

Finally, the power requirement is also affected by the type of machine being used. Different machines require different amounts of power to move the cutting tool. For example, a CNC machine requires more power than a manual machine.

What is difference between cutting speed and rpm?

The difference between cutting speed and RPM (revolutions per minute) is that cutting speed is the speed at which the cutting tool moves through the material being cut, while RPM is the number of revolutions the cutting tool makes in a minute. Cutting speed is typically measured in meters per minute (m/min) or feet per minute (ft/min), and is determined by the type of material being cut, the type of cutting tool being used, and the desired finish of the cut. RPM, on the other hand, is a measure of the rotational speed of the cutting tool, and is typically measured in revolutions per minute (RPM).

The relationship between cutting speed and RPM is that the higher the RPM, the faster the cutting speed. This is because the cutting tool is spinning faster, allowing it to cut through the material more quickly. However, it is important to note that the cutting speed should not exceed the recommended RPM for the cutting tool, as this can cause the tool to overheat and wear out prematurely.

What is the difference between spindle speed and cutting speed?

The difference between spindle speed and cutting speed is that spindle speed is the rotational speed of the spindle on a machine tool, while cutting speed is the speed at which the cutting tool moves through the material being machined. Spindle speed is measured in revolutions per minute (RPM), while cutting speed is measured in surface feet per minute (SFM).

Spindle speed is the speed at which the spindle rotates, and is typically set by the operator before the machining process begins. This speed is determined by the type of material being machined, the size of the tool being used, and the desired finish of the part. The spindle speed is usually set to a constant speed throughout the machining process.

Cutting speed, on the other hand, is the speed at which the cutting tool moves through the material being machined. This speed is determined by the type of material being machined, the size of the tool being used, and the desired finish of the part.

What is the difference between cutting speed and feed rate?

The difference between cutting speed and feed rate is that cutting speed is the speed at which the cutting tool moves through the material being cut, while feed rate is the speed at which the material is fed into the cutting tool. Cutting speed is typically measured in surface feet per minute (SFM) or meters per minute (MPM), while feed rate is typically measured in inches per minute (IPM) or millimeters per minute (MMPM).

Cutting speed is the speed at which the cutting tool moves through the material being cut. It is determined by the type of material being cut, the type of cutting tool being used, and the desired finish of the cut. Generally, the higher the cutting speed, the faster the cutting process will be. However, if the cutting speed is too high, it can cause the cutting tool to wear out faster and produce a poor quality cut.

Feed rate is the speed at which the material is fed into the cutting tool. It is determined by the type of material being cut, the type of cutting tool being used, and the desired finish of the cut