Are you curious about the difference between DNC and CNC? Look no further! In this article, we will delve into the distinctions between these two commonly used programming techniques in the manufacturing industry. Understanding these differences can help you make informed decisions when choosing the most suitable method for your operations.

Before we dive into the specifics, let’s briefly explain what DNC and CNC stand for. DNC, or Direct Numerical Control, involves connecting multiple CNC machines to a centralized computer for streamlined management and coordination. On the other hand, CNC, or Computer Numerical Control, relies on a computer interface for individual machines, allowing real-time adjustments and precise machining operations.

Now that we have a high-level overview, let’s explore the specifics. In the following sections, we will delve into the intricacies of NC, CNC, and DNC, their advantages, disadvantages, and the components that make up their systems. By the end of this article, you will have a clear understanding of the differences between these techniques and their ideal applications.

What is NC?

NC, short for Numerical Control, is a machine programming technique that revolutionized the manufacturing industry. It utilizes punched tape to provide precise machining instructions to the cutting tool. The punched tape contains a series of holes representing different commands and is fed into a tape reader for analysis. The tape reader interprets the instructions and sends them to the NC controller, which acts as the brain of the machine.

The NC controller translates the instructions into specific movements of the cutting tool using the machine transmission. This allows for accurate positioning and machining operations. NC machines typically have a three-axis system consisting of the X, Y, and Z axes (horizontal, vertical, and depth movement) to operate in a three-dimensional space. The movements of these axes are controlled by the NC controller based on the instructions from the punched tape.

NC was introduced in the mid-20th century and played a significant role in automating manufacturing processes. It replaced manual control with a more efficient and precise system, improving productivity and reducing human error. Although NC machines are commonly associated with punched tape, modern variations of NC often utilize digital interfaces and controllers.

NC is commonly used in low-volume production situations, where the machining instructions do not require frequent changes. Its application can be found in various industries such as automotive, aerospace, and electronics, where precision and repeatability are crucial.

Advantages of NC:

- Precise machining operations

- Consistency in part production

- Reduced human error

- Improved productivity

Disadvantages of NC:

- Limitations in flexibility and adaptability

- Restricted to low-volume production

- Requires expertise in programming and operation

| NC | CNC | DNC |

|---|---|---|

| Uses punched tape | Uses computer interface | Connects multiple CNC machines to a centralized computer |

| Ideal for low-volume production | Offers real-time adjustments and precision | Efficient for managing multiple machines in large-scale operations |

| Less complex and more affordable | Higher initial investment | Long-term cost savings potential |

What is CNC?

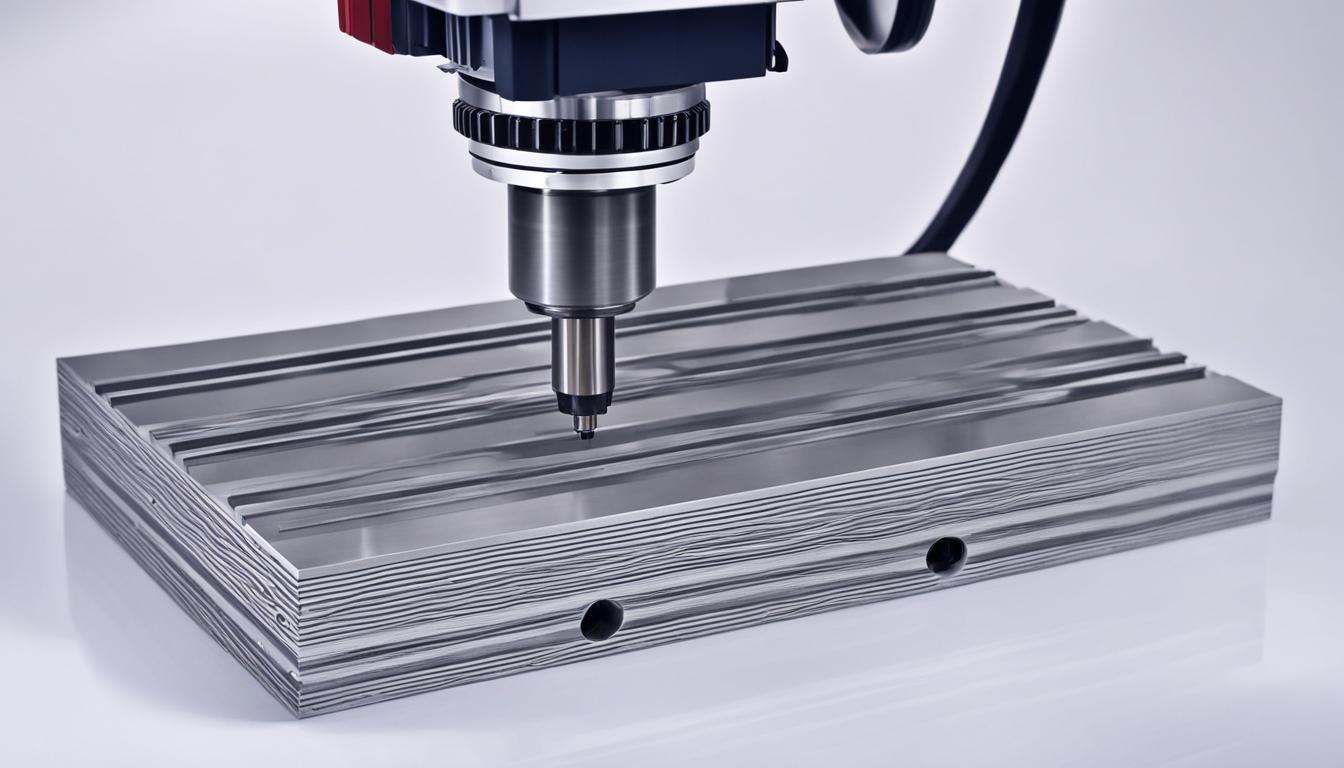

CNC, or Computer Numerical Control, is the computerized version of NC. It utilizes advanced technology to control the motion of machines, offering precise and efficient machining operations. CNC machines are programmed using CAD/CAM software, which allows users to create a digital design of the desired part and convert it into a part program that the machine can read and execute.

CNC machines have revolutionized the manufacturing industry by automating processes, reducing human errors, and improving productivity. With CNC, manufacturers can achieve high levels of accuracy and consistency in their production. These machines are widely used in various industries such as automotive, aerospace, and electronics.

Advantages of CNC Machines

- Real-time adjustments: CNC machines offer the flexibility to make real-time adjustments to the machining operations, allowing for quick modifications and optimizations.

- Precision and accuracy: With CNC, manufacturers can achieve precise and accurate machining results, ensuring the quality and consistency of the produced parts.

- Efficient production: CNC machines allow for efficient production processes, reducing lead times and increasing productivity.

CAD/CAM Software for CNC

In order to program CNC machines, manufacturers use CAD/CAM software. CAD (Computer-Aided Design) software is used to create a detailed digital model of the part, including its dimensions and specifications. CAM (Computer-Aided Manufacturing) software then takes the CAD model and generates the toolpaths and instructions necessary to produce the part.

CAD/CAM software offers a range of features and capabilities that enhance the productivity and efficiency of CNC machining. It allows for complex designs, 3D modeling, simulation, and optimization of machining processes. This software plays a crucial role in maximizing the capabilities of CNC machines and ensuring accurate replication of the desired part.

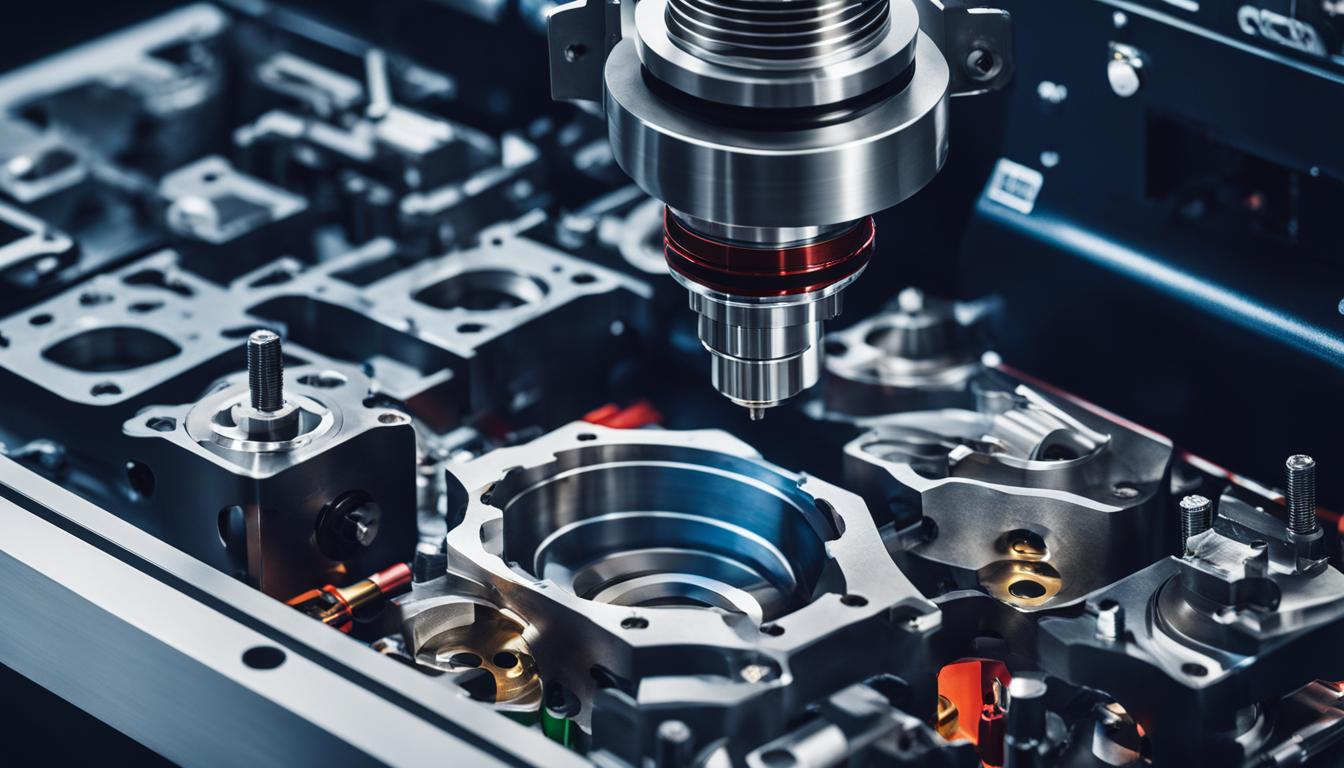

What is DNC?

DNC, or Direct Numerical Control, is a technique that revolutionizes manufacturing operations. It involves linking multiple CNC machines to a centralized computer, enabling efficient management and coordination.

In a DNC system, the required part programs are stored on the mainframe computer. The CNC machines are connected to this centralized computer either through a network or direct cabling. By doing so, the machines can directly access the part programs from the DNC system for execution.

DNC offers significant benefits, particularly in high volume production environments. Let’s explore some of its key advantages:

- Centralized Control: DNC allows for centralized control over multiple CNC machines, streamlining operations and reducing the need for multiple computers and machine operators. This centralized approach facilitates efficient production management and coordination.

- Improved Efficiency: By connecting CNC machines to a centralized computer, DNC minimizes operational delays and maximizes productivity. This eliminates the need for manual transfer of part programs and ensures seamless execution.

- Reduced Downtime: With DNC, CNC machines can access part programs directly from the central computer, eliminating delays caused by manual program transfer or file management. This significantly reduces machine downtime.

Here’s a simplified visualization of the DNC system:

| CNC Machine | CNC Machine | Centralized Computer |

|---|---|---|

| Connected to DNC System |

Connected to DNC System |

Stores Part Programs |

| Accesses Part Programs for Execution |

Accesses Part Programs for Execution |

By utilizing DNC, manufacturers can optimize their production processes and achieve higher efficiency. The centralized control and direct access to part programs make it an invaluable tool in managing complex manufacturing operations.

Continue reading to explore the differences between NC, CNC, and DNC in the upcoming sections.

Difference between NC, CNC, and DNC

In the world of manufacturing, NC, CNC, and DNC are three programming techniques that play a crucial role in automating operational processes. While they might appear similar at first glance, there are significant differences between these techniques in terms of control mechanisms, capabilities, and applications.

NC: Numerical Control

NC, short for Numerical Control, is the oldest of the three techniques. It relies on punched tape technology to provide machining instructions to the cutting tool. The punched tape, containing a series of codes, is fed into a tape reader, which analyzes and translates the instructions for the NC controller. This controller then translates the instructions into precise movements of the cutting tool, enabling the desired machining operation. NC machines are typically used in low-volume production situations.

CNC: Computer Numerical Control

CNC, or Computer Numerical Control, is the computerized version of NC. It utilizes a computer interface, along with a microcontroller onboard the machine, to control the motion and operation of the machine. CNC machines are programmed using Computer-Aided Design/Computer-Aided Manufacturing (CAD/CAM) software. This software allows users to create a digital design of the desired part and convert it into a part program that the machine can read and execute. CNC machines offer the advantage of real-time adjustments, precise machining operations, and are suitable for both low and medium volume production.

DNC: Direct Numerical Control

DNC, or Direct Numerical Control, takes CNC a step further by connecting multiple CNC machines to a centralized computer. This setup allows for centralized control and coordination of the machines. The part programs are stored on the mainframe computer, and the CNC machines access and execute them directly from the DNC system. DNC is particularly beneficial in high-volume production environments where multiple machines need to be managed and coordinated efficiently. It streamlines operations, reduces the need for multiple computers and operators, and offers the potential for long-term cost savings.

Comparing NC, CNC, and DNC

Now that we have explored the individual characteristics of NC, CNC, and DNC, let’s compare them to understand the differences:

| Technique | Main Control Mechanism | Application | Cost and Maintenance |

|---|---|---|---|

| NC | Punched tape | Basic, repetitive tasks | Low-cost, low maintenance |

| CNC | Computer interface | Real-time adjustments, intricate designs | Higher initial investment, routine maintenance required |

| DNC | Centralized computer | Large-scale operations, machine coordination | Potential long-term cost savings |

As seen in the comparison table, each technique has its own unique control mechanism, applications, and cost implications. NC is ideal for basic, repetitive tasks, while CNC offers real-time adjustments and is suitable for intricate designs. DNC, with its centralized control and coordination capabilities, is best suited for large-scale operations where multiple machines need to work in harmony.

Advantages of DNC over CNC

DNC, or Direct Numerical Control, offers several advantages over CNC, or Computer Numerical Control, in manufacturing operations. These advantages contribute to increased efficiency, streamlined operations, and improved data management.

One of the key advantages of DNC is its centralized control system. With DNC, multiple machines can be managed and coordinated from a single control point. This centralized control allows for better coordination of manufacturing processes, reducing the need for individual machine adjustments and minimizing the risk of errors.

DNC also improves data management in manufacturing operations. It facilitates efficient storage, retrieval, and analysis of part programs. With DNC, part programs can be stored in a centralized location, making it easier to access and manage them. This ensures that the correct program is readily available for each machine, reducing downtime and increasing productivity.

An important benefit of DNC is the flexibility it offers in updating and modifying machine instructions. With CNC, making changes to machine instructions would require adjusting each machine individually. However, with DNC, updates can be made centrally, and the changes can be applied to multiple machines simultaneously. This flexibility saves time and effort, especially in cases where frequent changes are needed.

In addition to these advantages, DNC can also lead to long-term cost savings. By implementing a centralized system with one computer and one machine operator handling multiple machines, operational costs can be reduced. This eliminates the need for multiple computers and machine operators, resulting in decreased maintenance and labor expenses.

Overall, DNC offers significant benefits over CNC in terms of centralized control, improved data management, flexibility in machine instructions, and long-term cost savings. These advantages make DNC a favorable choice in large-scale manufacturing environments where efficient coordination and streamlined operations are crucial.

Disadvantages of CNC Machines

While CNC machines offer precision and versatility, they also have some disadvantages. It’s important to consider these limitations when deciding whether to implement CNC technology in your manufacturing operations.

1. High Initial Investment

One of the main disadvantages of CNC machines is the higher initial investment compared to traditional machining methods. Top-tier CNC machines, which offer advanced features and capabilities, can be quite costly. This upfront expense can make it challenging for small businesses or those with limited budgets to adopt CNC technology.

2. Routine Maintenance

To ensure optimal performance and longevity, CNC machines require regular maintenance. Routine maintenance tasks such as cleaning, lubrication, and calibration are essential to keep the machines in good working condition. However, this maintenance effort adds to the overall cost of operating CNC machines.

3. Skill Requirements

CNC machines require skilled technicians to program and operate them effectively. The complexity of the computer interface and the need for comprehensive training can be a limitation for some operators. Employing and training skilled technicians can increase labor costs for businesses.

4. Limited Flexibility

While CNC machines offer high precision and accuracy, they can have limitations in terms of flexibility. These machines are typically optimized for specific machining operations and may not be as adaptable to a wide range of tasks. Adjusting the machine for different parts or processes may require additional setup time and adjustments.

5. Potential Downtime

If a CNC machine experiences a technical issue or breakdown, it can result in production downtime. Troubleshooting and resolving these issues can take time, affecting productivity and potentially causing delays in fulfilling orders. Having backup plans or redundancy in CNC machines is essential to minimize the impact of potential downtime.

Despite these disadvantages, CNC machines continue to be widely used in various industries due to their many advantages. However, businesses should carefully consider these limitations and evaluate their specific needs and capabilities before investing in CNC technology.

| Disadvantages | Impact |

|---|---|

| High Initial Investment | Financial challenge for small businesses and limited budgets |

| Routine Maintenance | Increase in overall operating cost |

| Skill Requirements | Increase in labor costs and training investment |

| Limited Flexibility | Potential setup time and adjustments for different tasks |

| Potential Downtime | Possible production delays and impact on order fulfillment |

Components of a CNC or DNC System

CNC (Computer Numerical Control) and DNC (Direct Numerical Control) systems are comprised of several essential components that work together to enable efficient and precise machining operations.

1. Machine Interface

The machine interface serves as a communication bridge between the CNC or DNC machine and its control system. It allows for the exchange of instructions, data, and feedback between the machine and the computer.

2. Drive Motors

Drive motors play a crucial role in propelling the movement of the CNC or DNC machine with accuracy. These motors provide the necessary power and control to ensure precise positioning and motion of the machine’s cutting tool.

3. Feedback System

The feedback system is responsible for monitoring the operations of the machine and ensuring that it operates within specified parameters. This system collects data on the machine’s performance and feeds it back to the control software for analysis and adjustments.

4. Control Software

The control software is the brain of the CNC or DNC system. It interprets the programmed instructions and dictates the machine’s movements, operations, and tool changes. This software translates the user’s design or code into actions that the machine can execute.

These components, when combined, create a functional CNC or DNC system that allows for precise control and automation of machining processes.

Conclusion

In conclusion, NC, CNC, and DNC are programming techniques used in manufacturing to automate operational processes. Each technique has its own unique characteristics and applications. NC, the oldest technique, relies on punch tapes and tape readers for machine programming. CNC, the modernized version, utilizes a computer to program the code and offers real-time adjustments. DNC connects multiple CNC machines to a centralized computer, providing centralized control and improved efficiency.

The choice between these techniques depends on the specific needs and requirements of the manufacturing operation. NC is suitable for basic, repetitive tasks, while CNC offers precision and real-time adjustments for intricate designs. DNC is ideal for large-scale operations that require coordination and centralized management of multiple machines. Understanding the differences and advantages of these techniques is crucial for businesses to optimize their manufacturing processes.

Additionally, the cost and maintenance requirements vary among these techniques. NC is generally cost-effective, while CNC may require a higher initial investment. DNC, on the other hand, offers potential long-term cost savings by implementing a centralized system. The decision to adopt NC, CNC, or DNC should be based on a comprehensive analysis of the manufacturing needs, budget, and long-term goals of the business.

Overall, NC, CNC, and DNC play integral roles in streamlining and automating manufacturing processes. By understanding their capabilities, advantages, and applications, businesses can make informed decisions to optimize their production workflows and stay competitive in today’s rapidly evolving manufacturing landscape.

Explaining the Difference between DNC and CNC Systems

DNC and CNC systems are two distinct approaches to automation in manufacturing. Understanding their differences is crucial in choosing the most suitable solution for a manufacturing operation. Let’s explore the characteristics that set DNC and CNC systems apart.

DNC: Centralized Control and Coordination

DNC, or Direct Numerical Control, is a network of multiple CNC machines connected to a centralized computer. This architecture allows for centralized control and coordination of the machines. In a DNC system, the main computer stores and manages the part programs, while the CNC machines access these programs for execution.

Benefits of DNC:

- Centralized control of multiple machines

- Efficient coordination and management in large-scale operations

- Streamlined workflow and improved efficiency

CNC: Real-time Adjustments and Precise Machining

CNC, or Computer Numerical Control, is a computerized numerical control system that operates on individual machines. Each CNC machine has its own computer interface, which allows for real-time adjustments and precise machining operations. CNC machines are programmed using CAD/CAM software and offer a high level of control and flexibility in manufacturing processes.

Benefits of CNC:

- Real-time adjustments for precise machining operations

- Wide range of applications across industries

- Cost-effective and suitable for small to large-scale production

Understanding the difference between DNC and CNC systems is essential for optimizing manufacturing processes. While DNC provides centralized control and coordination, CNC offers real-time adjustments and precision. The choice between these systems depends on the specific needs and requirements of the manufacturing operation.

| DNC | CNC | |

|---|---|---|

| Control | Centralized control and coordination | Individual machine control |

| Applications | Best suited for large-scale operations | Widely used across industries |

| Flexibility | Streamlined workflow and centralized management | Real-time adjustments and precise machining |

| Cost | Potential long-term cost savings | Initial investment required |

Exploring the Usage Scenarios for DNC and CNC Systems

When it comes to manufacturing processes, DNC (Direct Numerical Control) and CNC (Computer Numerical Control) systems offer different usage scenarios based on their unique capabilities.

DNC systems are an excellent choice for large businesses that specialize in the production of repeated parts or objects. Their centralized control and coordination capabilities make them highly efficient for managing multiple machines simultaneously. By connecting machines to a centralized computer, DNC enables seamless control and coordination, resulting in streamlined operations and improved productivity.

On the other hand, CNC machines are widely used across various industries ranging from small businesses to large-scale industries. Thanks to their cost-effectiveness, operational simplicity, and precision, CNC machines find application in a wide range of tasks. Whether it’s small scale production or high-volume manufacturing, CNC machines offer the flexibility and accuracy required to meet diverse industry needs.

By understanding the specific usage scenarios for DNC and CNC systems, businesses can make informed decisions when implementing these technologies. Large manufacturers with repetitive part production can benefit from the centralized control and coordination of DNC systems. Meanwhile, CNC machines find their place in industries of all sizes, offering cost-effective and precise solutions for various applications.