The process of turning involves a series of coordinated movements and actions that result in a change of direction or orientation. It begins with a shift in body weight to the side opposite the intended turn direction. This weight shift initiates the rotation of the body, starting from the feet and moving upward through the legs, hips, torso, and finally the head. The eyes typically lead the turn, focusing on the new direction before the body fully rotates. As the turn progresses, the arms may be used for balance and to help control the speed and precision of the movement.

The feet play a crucial role, with the outer foot pushing off to generate momentum while the inner foot pivots. For sharper turns, a person might step into the turn, crossing one foot over the other. The rate of rotation and the degree of turn can vary greatly depending on the specific situation, from a slight adjustment in direction to a complete 180-degree turn. Factors such as speed, surface friction, and the individual’s physical capabilities all influence the execution of the turn. Mastering the process of turning is essential for various activities, including dance, sports, and everyday movements like navigating through crowded spaces or changing direction while walking.

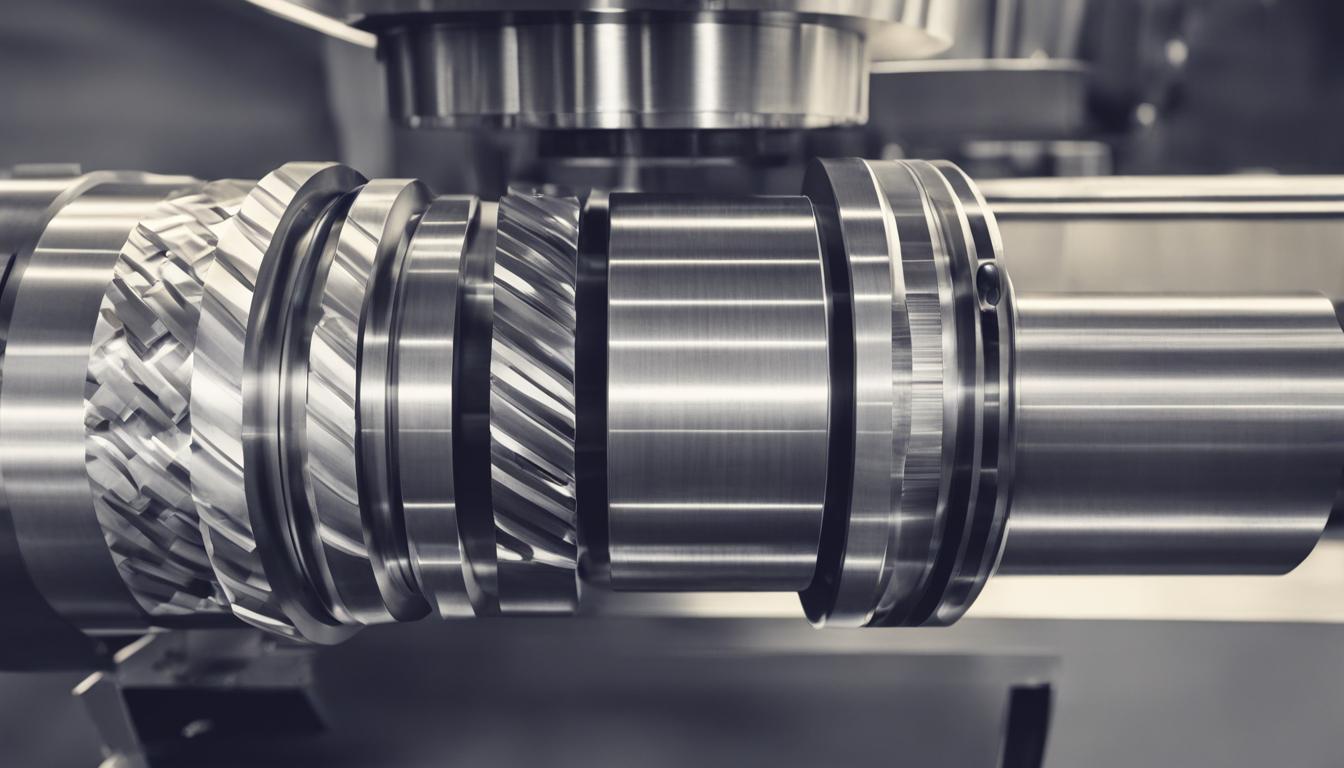

The Working Principle of Turning

The working principle of turning involves rotating the workpiece on a lathe machine while a single-point cutting tool moves along the surface of the workpiece to remove material. The cutting tool cuts into the workpiece to achieve the desired shape and dimensions. The speed at which the tool moves and the rotational speed of the workpiece determine the cutting speed.

The cutting speed, along with other parameters like feed rate and depth of cut, influences the surface finish and dimensional accuracy of the final part. By controlling these parameters, operators can achieve precise cuts and shape the workpiece to the desired specifications.

- The workpiece is mounted on a lathe machine.

- The cutting tool is positioned near the workpiece surface.

- The workpiece is rotated at a controlled speed.

- The cutting tool moves along the workpiece surface, cutting into it.

- Material is removed from the workpiece, shaping it according to the desired specifications.

- The cutting speed, feed rate, and depth of cut are adjusted to achieve the desired surface finish and dimensions.

- The process is repeated until the workpiece is completely machined.

By understanding the working principle of turning, manufacturers can effectively utilize this machining process to create precise and customized parts.

| Advantages | Disadvantages |

|---|---|

| Highly precise and accurate results | Not suitable for complex shapes or features |

| Produces excellent surface finish | Requires skilled operators |

| Can handle a wide range of materials | Slower production rates compared to other machining processes |

Steps of the Turning Process

The turning process involves several steps that are essential for achieving accurate and precise results. Each step contributes to shaping the workpiece to the desired specifications. Let’s take a closer look at the main steps involved in the turning process:

- Workpiece Preparation: The first step is to prepare the workpiece that will be turned. This involves selecting the appropriate material and ensuring it is clean and free from any defects or contaminants.

- Workpiece Mounting: Once the workpiece is ready, it needs to be securely mounted on the lathe machine. This ensures stability and prevents any movement or vibrations during the turning process.

- Tool Selection and Setup: Next, the appropriate cutting tool is selected based on the desired shape and material of the workpiece. The tool is carefully mounted and positioned in the tool holder, ensuring proper alignment and clearance angles.

- Tool Positioning and Feed: The cutting tool is positioned at the starting point on the workpiece surface. The feed rate is set to control the depth of cut as the tool moves along the workpiece. It is crucial to maintain a consistent and precise feed throughout the process.

- Cutting Process: With the tool in position, the cutting process begins. The lathe machine rotates the workpiece, allowing the cutting tool to remove material and shape the workpiece according to the desired specifications.

- Monitoring and Quality Check: Throughout the turning process, it is important to monitor the cutting conditions, such as cutting speed, feed rate, and tool wear. Regular inspections and measurements are performed to ensure the quality of the turning operation and the final part.

- Finishing Operations: After the desired shape is achieved, additional finishing operations may be performed to refine the surface finish or add specific features. These operations can include polishing, deburring, or applying coatings.

- Final Inspection: Once the turning process is complete, a final inspection is conducted to verify that the workpiece meets all the required specifications. This ensures that the finished part is accurate, dimensionally precise, and free from any defects.

The turning process steps outlined above provide a general overview of the process. The actual steps may vary depending on the complexity of the workpiece, the type of lathe machine used, and specific machining requirements.

Types of Turning Processes

Turning is a versatile machining process that offers different types of turning processes suited to specific applications. Each type of turning process has its own unique characteristics and advantages. Let’s explore some of the commonly used types of turning processes:

1. Straight Turning

Straight turning is the most basic type of turning process. It involves removing material along a straight path to create cylindrical shapes. Straight turning is commonly used for producing simple cylindrical parts, such as shafts and rods.

2. Taper Turning

Taper turning is the process of gradually reducing the diameter of a cylindrical workpiece from one end to the other, creating a tapered shape. This type of turning is often used for creating parts with conical features, such as conical pins and mandrels.

3. Facing

The facing process involves cutting material from the end of the workpiece to create a flat surface. It is commonly used to produce flat-faced components, such as gears and flanges.

4. Thread Cutting

Thread cutting is the process of creating screw threads on a workpiece. It can be done using a single-point cutting tool or a threading insert. Thread cutting is essential for creating threaded components, such as bolts, nuts, and screws.

5. Knurling

Knurling is a process that creates a pattern of raised ridges on the surface of a workpiece. This enhances the grip and aesthetics of the part. Knurling is often used for applications that require improved gripping surfaces, such as handles and knobs.

6. Grooving

Grooving involves cutting a groove or channel on the surface of the workpiece. It is commonly used for creating features like O-ring grooves, keyways, and slots.

| Turning Process | Application |

|---|---|

| Straight Turning | Shafts, rods |

| Taper Turning | Conical pins, mandrels |

| Facing | Gears, flanges |

| Thread Cutting | Bolts, nuts, screws |

| Knurling | Handles, knobs |

| Grooving | O-ring grooves, keyways, slots |

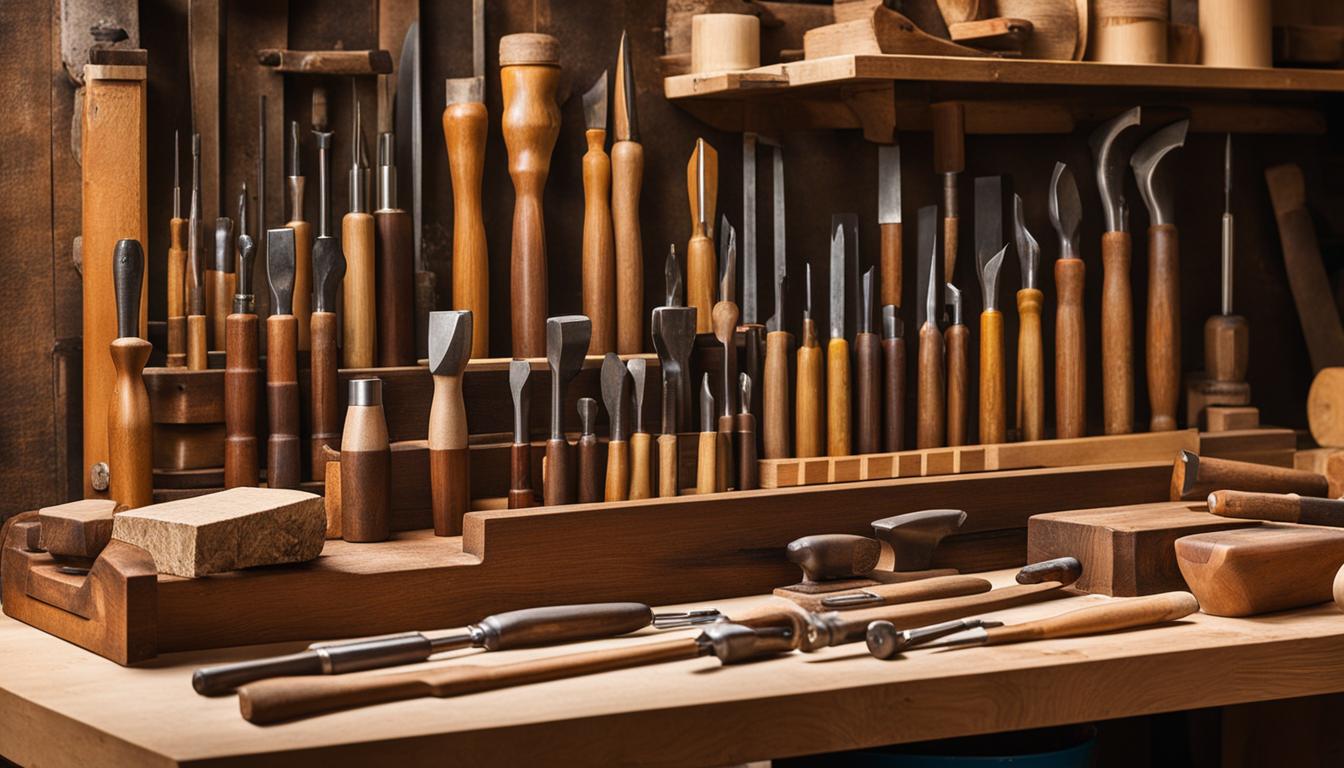

Tools and Equipment in Turning

Turning is a precision machining process that requires specific tools and equipment to achieve accurate results. The selection of the right tools and equipment in turning plays a crucial role in achieving desired shapes, dimensions, and surface finishes. Here are some of the key tools and equipment used in turning:

- Lathe Machine: The lathe machine is the primary equipment used in turning. It rotates the workpiece and holds the cutting tool, allowing for precise shaping and material removal.

- Chuck: The chuck is a device used to securely hold and rotate the workpiece during the turning process. It provides stability and ensures the workpiece remains in place.

- Tool Holder: The tool holder is an essential component that holds and positions the cutting tool. It provides stability and allows for tool adjustments to achieve specific cutting parameters.

- Cutting Tools: Various types of cutting tools are used in turning, including carbide inserts, high-speed steel (HSS) tools, and diamond tools. These cutting tools are selected based on the material being turned and the desired cutting conditions.

- Tool Inserts: Tool inserts are replaceable cutting tips that are mounted on the cutting tools. They come in different shapes and cutting angles to suit specific turning applications.

- Coolant System: The coolant system is used to cool the cutting tool and workpiece during the turning process. It helps reduce heat build-up, improve cutting performance, and prolong tool life.

- Measuring Tools: Measuring tools such as calipers, micrometers, and depth gauges are used to ensure dimensional accuracy and quality control during the turning process.

By having the right tools and equipment, turning operators can effectively shape workpieces and achieve precise results that meet the required specifications.

Parameters in Turning

In the turning process, several parameters play a crucial role in determining the quality and efficiency of the machining operation. By carefully adjusting these parameters, operators can achieve optimal results and meet the desired specifications for the finished part.

1. Cutting Speed:

The cutting speed refers to the speed at which the cutting tool moves along the surface of the rotating workpiece. It is typically measured in surface feet per minute (SFPM) or meters per minute (MPM). Higher cutting speeds can result in improved productivity but may also cause excessive tool wear. On the other hand, lower cutting speeds may enhance tool life but can lead to longer machining times.

2. Feed Rate:

The feed rate represents the distance that the cutting tool advances into the workpiece per revolution. It is typically measured in inches per revolution (IPR) or millimeters per revolution (mm/rev). The feed rate affects material removal rate, chip formation, and surface finish. It is essential to optimize the feed rate to maximize material removal while maintaining surface quality.

3. Depth of Cut:

The depth of cut refers to the distance between the original and final positions of the cutting tool in the workpiece. The depth of cut affects chip thickness, cutting forces, and tool life. It is necessary to control the depth of cut to prevent excessive stress on the cutting tool and ensure dimensional accuracy.

4. Tool Geometry:

The geometry of the cutting tool, including angles, rake angles, and clearance angles, greatly influences cutting performance. Proper tool geometry selection can enhance chip evacuation, reduce cutting forces, and improve surface finish. Different tool geometries are suitable for specific materials and cutting conditions.

5. Coolant/Lubrication:

The use of coolants or lubricants during the turning process helps dissipate heat, lubricate the cutting edge, and flush away chips. This improves tool life, surface finish, and overall machining performance. The choice of coolant/lubricant depends on the material being machined and the specific turning operation.

To illustrate the influence of these parameters, below is a table showcasing the impact of different cutting speeds, feed rates, and depths of cut on the machining performance:

| Cutting Speed (SFPM) | Feed Rate (IPR) | Depth of Cut (inches) | Result |

|---|---|---|---|

| 300 | 0.005 | 0.050 | Good surface finish, low material removal rate |

| 600 | 0.010 | 0.040 | Optimal balance of surface finish and material removal rate |

| 900 | 0.015 | 0.030 | High material removal rate, rough surface finish |

By understanding and carefully adjusting these parameters, operators can optimize the turning process and achieve the desired outcomes for their machining operations.

Supported Materials for Turning

Turning is a versatile machining process that can be applied to a wide range of materials. Depending on the material and its characteristics, different cutting tools and machining parameters may be required to achieve optimal results. Here are some commonly supported materials for turning:

- Metals:

- Alloy steel

- Carbon steel

- Stainless steel

- Aluminum

- Brass

- Copper

- Titanium

- Plastics:

- Acrylic

- Polyethylene

- Polypropylene

- PVC

- Delrin

- Nylon

- Ceramics:

- Alumina

- Zirconia

- Silicon nitride

- Carbide

- Composites:

- Carbon fiber reinforced polymer (CFRP)

- Glass fiber reinforced polymer (GFRP)

- Aramid fiber reinforced polymer (AFRP)

- Metal matrix composites (MMC)

These are just a few examples of the materials that can be effectively turned. The selection of the material will depend on the specific application, desired properties of the finished part, and the machining capabilities of the turning equipment.

Advantages and Disadvantages of Turning

Turning offers several advantages and disadvantages that should be considered when deciding on the appropriate machining process.

Advantages of Turning

- High Precision: Turning allows for precise shaping and dimensional control, producing parts with tight tolerances.

- Versatility: It is compatible with a wide range of materials, including metals, plastics, ceramics, and composites.

- Cost-effective: Turning is a cost-effective method for producing large quantities of parts with consistent quality.

- Efficient Material Removal: The turning process efficiently removes material, reducing waste and optimizing material usage.

- Time-saving: With high cutting speeds and rapid tool movements, turning can produce parts quickly, improving manufacturing efficiency.

Disadvantages of Turning

- Complexity: Turning can be a complex process that requires skilled operators to set up and monitor machining parameters.

- Limitations on Shape Complexity: It is best suited for producing rotational symmetric shapes, limiting its applicability for complex geometries.

- Surface Finish: Turning can result in a rough surface finish, requiring additional post-processing operations to achieve the desired surface quality.

- Tool Wear: Continuous cutting can lead to tool wear, necessitating frequent tool changes or sharpening.

- Limited Intricate Features: Turning may have limitations in producing intricate internal features and small details on the part.

Despite the disadvantages, turning remains a widely used machining process due to its versatility, precision, and cost-effectiveness.

Design Tips for Turning

When designing parts for the turning process, it is important to consider various design considerations and guidelines to optimize the manufacturing process and achieve the desired results. Here are some design tips for turning:

- Material Selection: Choose the appropriate material for your turning project based on its machinability, mechanical properties, and compatibility with the desired surface finish and dimensional accuracy.

- Geometry: Design the part with proper geometry to ensure smooth chip evacuation, minimize tool deflection, and achieve the desired shape and features.

- Tool Selection: Select the right cutting tool for the specific material and geometry of your part. Consider factors such as tool material, cutting speed, feed rate, and insert geometry.

- Clearance and Tolerances: Provide sufficient clearance and tolerances to accommodate the tool movement and ensure proper fit and functionality of the final part.

- Avoid Overhangs: Minimize unsupported overhangs in the part design to reduce the risk of tool chatter, deflection, and poor surface finish.

- Consider Diameters: Design the part with appropriate diameters to optimize the cutting forces, tool life, and surface finish. Avoid sudden diameter transitions that may cause tool vibration.

- Surface Finish: Specify the desired surface finish requirements to ensure the appropriate cutting parameters and tool selection. Consider post-processing options if a higher surface finish is required.

- Chamfers and Fillets: Incorporate chamfers and fillets in the part design to reduce stress concentration, improve tool life, and enhance the overall aesthetics of the final part.

- Minimize Parting-Off: Minimize the need for parting-off operations by optimizing the part design to avoid the creation of separate pieces that require additional machining.

- Consider Part Orientation: Optimize the part orientation during machining to minimize setup adjustments, tool changes, and overall machining time.

By considering these design tips for turning, you can enhance the efficiency and effectiveness of the turning process, resulting in high-quality finished parts that meet your desired specifications.

Software Tools for Turning Process Optimization

Turning is a complex machining process that requires precision and expertise. To enhance efficiency and accuracy, various software tools are available to assist in every step of the turning process. These software tools offer advanced functionalities, enabling manufacturers to design, program, simulate, and optimize the turning operation.

One popular software used in turning is [Brand Name], a powerful tool that allows users to create detailed part designs with ease. With its intuitive interface and comprehensive features, [Brand Name] simplifies the design process and ensures optimal results. Additionally, [Brand Name] enables users to generate tool paths and program the cutting process, streamlining the programming phase.

Another indispensable software tool in turning is [Brand Name], which offers extensive simulation capabilities. With [Brand Name], users can simulate the entire turning process, providing a virtual representation of the machining operation. This simulation allows manufacturers to identify potential issues, optimize cutting parameters, and validate the tool path before executing the actual process.

Additionally, [Brand Name] provides optimization algorithms that fine-tune the cutting parameters, such as speed, feed rate, and depth of cut, to maximize performance and efficiency. By leveraging these software tools, manufacturers can minimize errors, reduce setup time, and achieve higher productivity in the turning process.