Welding with electrodes is a process that involves joining two pieces of metal together by melting them together with an electric arc. It is a common welding technique used in many industries, and it is relatively easy to learn.

The first step in welding with electrodes is to prepare the metal pieces that you are going to be joining. This includes cleaning the metal surfaces, removing any rust or dirt, and ensuring that the pieces are properly aligned. Once the pieces are ready, you will need to select the appropriate electrode for the job. Different electrodes are designed for different types of metals and welding processes, so it is important to select the right one.

Once the electrode is selected, you will need to set up the welding machine. This includes connecting the electrode to the power source, setting the current and voltage, and adjusting the arc length. It is important to ensure that the settings are correct for the type of metal and welding process that you are using.

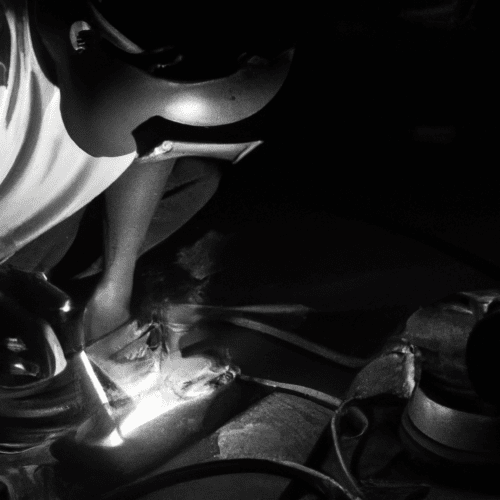

Once the machine is set up, you can begin welding. The process involves striking an arc between the electrode and the metal pieces, and then feeding the electrode into the arc. As the electrode melts, it will form a molten pool of metal that will join the two pieces together. It is important to keep the arc length consistent and to move the electrode slowly and steadily to ensure a good weld.

Once the weld is complete, you will need to clean up the area. This includes removing any slag or spatter that may have formed during the welding process. It is also important to inspect the weld to ensure that it is strong and free of defects.

Welding with electrodes is a relatively simple process, but it is important to take the time to learn the proper techniques and safety procedures. With practice, you can become an expert welder and create strong, reliable welds.

What is the easiest rod to weld with?

The easiest rod to weld with depends on the type of welding you are doing and the material you are welding. Generally speaking, the easiest rod to weld with is a mild steel rod, such as an E6010 or E7018. These rods are designed to be easy to use and provide good penetration and strength. They are also relatively inexpensive and widely available. For welding aluminum, the easiest rod to use is an aluminum-specific rod, such as an ER4043 or ER5356. These rods are designed to be easy to use and provide good penetration and strength when welding aluminum. They are also relatively inexpensive and widely available. For welding stainless steel, the easiest rod to use is an austenitic stainless steel rod, such as an ER308L or ER316L. These rods are designed to be easy to use and provide good penetration and strength when welding stainless steel. They are also relatively inexpensive and widely available. Ultimately, the easiest rod to weld with depends on the type of welding you are doing and the material you are welding.

What are the 3 types of electrode?

The three types of electrodes are:

1. Galvanic Electrodes: These are electrodes that are used to measure the electrical potential of a solution. They are made of two different metals that are placed in the solution and connected to a voltmeter. The voltmeter measures the difference in electrical potential between the two metals, which is then used to calculate the concentration of the solution.

2. Reference Electrodes: These are electrodes that are used to measure the electrical potential of a solution relative to a known reference point. They are typically made of a metal such as silver or copper and are connected to a voltmeter. The voltmeter measures the difference in electrical potential between the reference electrode and the solution, which is then used to calculate the concentration of the solution.

3. Indicator Electrodes: These are electrodes that are used to measure the pH of a solution. They are typically made of a metal such as silver or copper and are connected to a pH meter. The pH meter measures the difference in electrical potential between the indicator electrode and the solution.

How does an electrode work?

An electrode is a device that is used to transfer electrical energy between a conductor and a non-conductor. It is typically composed of a metal or other conductive material, such as graphite, that is connected to a power source. The electrode is then placed in contact with the material to be tested, and a current is passed through the material. This current causes electrons to flow from the electrode to the material, creating an electrical field. This field can be used to measure the electrical properties of the material, such as its resistance, capacitance, and inductance.

The electrode can also be used to transfer energy from one material to another. For example, in electroplating, an electrode is used to transfer metal ions from a solution to a substrate. The metal ions are attracted to the electrode, and as they move towards it, they deposit onto the substrate, forming a thin layer of metal.

What is the difference between electrode and welding rod?

The terms electrode and welding rod are often used interchangeably, but they are actually two different things. An electrode is a metal rod that is used to conduct electricity in an arc welding process. It is connected to the welding machine and is used to create an electric arc between the metal being welded and the electrode. The electrode is consumed during the welding process and must be replaced periodically.

A welding rod, on the other hand, is a consumable filler metal that is used to join two pieces of metal together. It is made of a metal alloy that melts at a lower temperature than the base metals being welded. The welding rod is melted by the heat of the arc created by the electrode and is used to fill the gap between the two pieces of metal. The welding rod is also consumed during the welding process and must be replaced periodically.

Do we always use electrode in welding?

No, welding does not always require the use of an electrode. There are several different types of welding processes that do not require the use of an electrode. These include oxy-fuel welding, which uses a fuel gas and oxygen to create a flame that melts the metal, and resistance welding, which uses electrical current to heat the metal and create a weld. Other welding processes, such as laser welding and electron beam welding, also do not require the use of an electrode. Each of these processes has its own advantages and disadvantages, so it is important to consider the specific application when deciding which welding process to use.