When it comes to milling aluminum, the type of milling cutter you should use depends on the type of aluminum you are working with, the size of the job, and the desired finish. Generally, aluminum is milled with high-speed steel (HSS) or carbide cutters. HSS cutters are typically used for smaller jobs and for roughing cuts, while carbide cutters are used for larger jobs and for finishing cuts.

For roughing cuts, a single-point cutting tool is often used. This type of cutter has a single cutting edge and is used to remove large amounts of material quickly. It is also used to create a flat surface. For finishing cuts, a multi-point cutting tool is often used. This type of cutter has multiple cutting edges and is used to create a smooth finish.

When selecting a milling cutter for aluminum, it is important to consider the type of aluminum you are working with, the size of the job, and the desired finish. The type of cutter you choose should be based on these factors.

What type of cutter is used for milling aluminum?

Milling aluminum requires a specialized type of cutter known as an end mill. End mills are designed specifically for cutting aluminum and other non-ferrous metals. They are typically made from high-speed steel or carbide and feature a variety of cutting edges, such as straight, helical, and spiral. The cutting edges are designed to cut through the aluminum quickly and efficiently, while also providing a smooth finish. End mills come in a variety of sizes and shapes, so it is important to select the right one for the job. For example, a larger end mill is better suited for cutting thicker aluminum, while a smaller end mill is better for cutting thinner aluminum. Additionally, end mills with a higher number of flutes are better for cutting aluminum, as they provide more cutting edges and a smoother finish.

Can you use carbide end mill on aluminum?

Yes, you can use a carbide end mill on aluminum. Carbide end mills are designed to be used on a variety of materials, including aluminum. Carbide end mills are made from a combination of tungsten carbide and cobalt, which makes them extremely hard and durable. This makes them ideal for machining aluminum, as they can withstand the high temperatures and pressures associated with the machining process. Additionally, carbide end mills are designed to be used with high-speed spindles, which can help to increase the speed and accuracy of the machining process.

When using a carbide end mill on aluminum, it is important to use the correct cutting parameters. This includes the speed, feed rate, and depth of cut. It is also important to use the correct coolant, as this can help to reduce heat buildup and improve the quality of the machined surface. Additionally, it is important to use the correct lubricant, as this can help to reduce friction and improve the life of the end mill.

Can you use 4 flute end mill aluminum?

Yes, you can use a 4 flute end mill to cut aluminum. End mills are designed to cut through a variety of materials, including aluminum, and the number of flutes on the end mill will determine the type of cut it can make. A 4 flute end mill is typically used for finishing cuts, as it has a smaller cutting surface than a 2 flute end mill. This makes it ideal for making precise, detailed cuts in aluminum. When using a 4 flute end mill to cut aluminum, it is important to use the correct cutting speed and feed rate. The cutting speed should be kept low to prevent the end mill from overheating, and the feed rate should be adjusted to ensure that the end mill is cutting at the correct depth. Additionally, it is important to use a lubricant when cutting aluminum with a 4 flute end mill, as this will help to reduce friction and heat buildup.

Is aluminum hard to mill?

Milling aluminum is not necessarily difficult, but it can be challenging due to the material’s properties. Aluminum is a soft metal that is relatively easy to cut, but it can be prone to tool wear and can be difficult to hold tight tolerances. It is also prone to work hardening, which can cause the material to become more difficult to cut as the cutting process progresses. To mill aluminum effectively, it is important to use the right tools and techniques. High-speed steel (HSS) tools are generally the best choice for milling aluminum, as they are designed to cut softer materials. It is also important to use sharp tools and to use a cutting fluid to reduce friction and heat buildup. Additionally, using a slower feed rate and a higher cutting speed can help to reduce tool wear and improve the surface finish. Finally, using a climb milling technique can help to reduce the risk of work hardening and can improve the surface finish.

What are the different type of milling cutter that are used in milling?

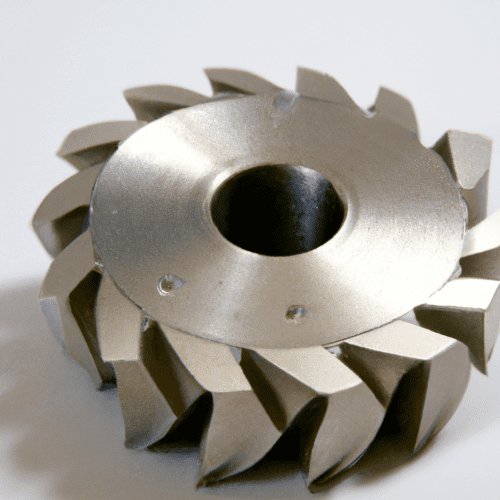

Milling cutters are cutting tools used in milling machines to perform milling operations. They come in a variety of shapes and sizes and are used for a variety of operations, including face milling, shoulder milling, and slotting. The most common types of milling cutters are end mills, slot drills, side and face cutters, dovetail cutters, and fly cutters.

End Mills are the most common type of milling cutter and are used for a variety of operations including face milling, shoulder milling, and slotting. They are typically made from high-speed steel or carbide and have two or four flutes. End mills are available in a variety of shapes and sizes, including square, ball nose, corner radius, and roughing end mills.

Slot Drills are similar to end mills but have a larger diameter and a shorter cutting length. They are used for plunge cutting and are available in a variety of shapes and sizes.

What is a fly cutter used for?

A fly cutter is a type of tool used in metalworking and woodworking to create a flat surface. It is a single-point cutting tool that is used to cut a flat surface on a workpiece. The fly cutter consists of a body that holds an arbor, which is a cylindrical shaft that holds the cutting tool. The cutting tool is typically a carbide insert, but can also be a high-speed steel (HSS) tool bit. The cutting tool is mounted on the arbor and is held in place by a set screw. The body of the fly cutter is then mounted on the spindle of a milling machine.

When the spindle is rotated, the cutting tool is spun around the arbor, creating a flat surface on the workpiece. The cutting tool is typically set at a specific depth, and the fly cutter is moved across the workpiece in a series of passes. The depth of the cut is determined by the depth of the cutting tool, and the width of the cut is determined by the diameter of the cutting tool.

How many types of milling cutters are there?

Milling cutters are cutting tools typically used in milling machines or machining centers to perform milling operations (and occasionally in other machine tools). They remove material by their movement within the machine (e.g., a ball nose mill) or directly from the cutter’s shape (e.g., a form tool such as a hobbing cutter).

There are several types of milling cutters, including:

1. End Mills: End mills are the most common type of milling cutters. They have cutting edges on the end and sides of the body and are used for making slots, grooves, and other features in a workpiece. They are available in a variety of shapes and sizes, and can be used for both roughing and finishing operations.

2. Slab Mills: Slab mills are large cutters that have a wide face and are used for making flat surfaces in a workpiece. They are available in a variety of sizes and shapes, and can be used for both roughing and finishing operations.