Metal milling is a technological process that involves shaping a variety of metal alloys using milling machines. These machines utilize different types of metals to produce parts or shapes with specific parameters. In this article, we will explore the metals used in milling machines and their significance in the machining process.

Metal milling is a form of shaving machining where excess material is removed using a high-speed spindle with a cutting tool. Various metals can be machined, including but not limited to stainless steel, aluminum, titanium, copper, and steel alloys. Each metal has its own unique properties and characteristics that make it suitable for specific applications.

For example, stainless steel is commonly used in CNC (computer numerical control) machining due to its strength and corrosion resistance. Aluminum, on the other hand, is lightweight and offers excellent machinability, making it a popular choice for industries such as aerospace and automotive.

Other metals used in milling machines include titanium, known for its high strength-to-weight ratio, and copper, which is valued for its excellent electrical conductivity. Steel alloys, such as carbon steel and tool steel, are also frequently machined in milling processes.

When selecting the appropriate metal for milling operations, factors such as the desired mechanical properties, corrosiveness of the environment, and intended application must be considered. The choice of metal will influence the selection of tools, cutting parameters, and overall machining strategy.

In conclusion, the metals used in milling machines play a crucial role in the machining process. Different metals offer distinct properties and advantages, allowing manufacturers to produce precise and high-quality parts. Understanding the characteristics of these metals is essential for achieving optimal results in milling operations.

Metal Milling Process: CNC and Automatic Milling

Metal milling is a machining process that utilizes routers to shape metal blocks by removing small parts of the material. This process is essential for creating precise and intricate metal components used in various industries.

The two main methods of metal milling are CNC milling and automatic milling. Each method has its advantages and is suitable for different production requirements.

CNC Milling

CNC milling, which stands for Computer Numerical Control milling, is a highly efficient and automated process. It involves using computer-controlled machines to precisely shape metal blocks according to the specified design. CNC milling machines follow pre-programmed instructions, allowing for accurate and repeatable production.

Advantages of CNC milling:

- High precision: CNC milling machines can achieve tight tolerances, ensuring consistent quality and dimension accuracy.

- Fast production: The automated nature of CNC milling enables faster production speeds, making it ideal for high-volume manufacturing.

- Complex designs: CNC milling machines can create intricate and complex shapes that may be challenging to achieve using traditional methods.

Automatic Milling

Automatic milling, also known as traditional milling, is a more manual approach to the metal milling process. It involves using manually operated machines or automatic milling machines with limited computer control.

Advantages of automatic milling:

- Flexibility: Automatic milling allows for versatile machining operations and is suitable for single or small quantity production.

- Cost-effective: Automatic milling may be a more cost-effective option for low-volume production or when utilizing existing manual machines.

- Operator skill: Automatic milling relies on the skill and expertise of the operator, making it a suitable method for experienced machinists.

Regardless of the method used, both CNC milling and automatic milling require careful selection of cutting tools and parameters based on the type of metal alloy being machined. The right tools and settings are crucial for achieving optimal results in terms of accuracy, surface finish, and overall efficiency.

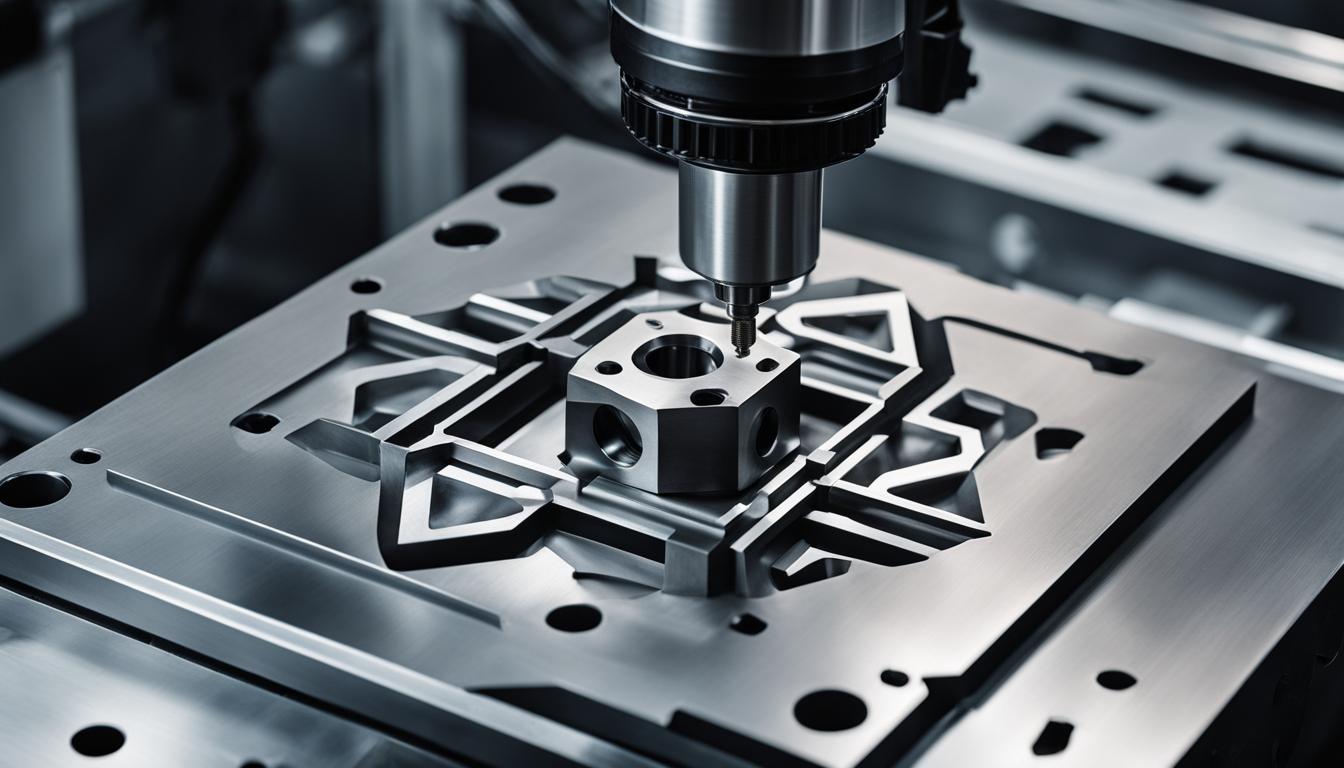

To provide a visual representation of the metal milling process, here is an image depicting a CNC milling machine:

Now, let’s take a closer look at the key components involved in the metal milling process and how they contribute to the overall milling operation.

Types of Metal Milling and Machining

Metal milling is a versatile machining process that encompasses various types based on spindle movement and machined surfaces. Understanding these types is crucial for optimizing the milling process and achieving desired outcomes. The two main types of metal milling based on kinetics are up-cut milling and climb milling.

Up-Cut Milling

In up-cut milling, the cutter rotates in the opposite direction to the spindle movement. This type of milling is highly efficient as it aggressively removes material, making it ideal for rapid material removal. However, up-cut milling may result in lower surface quality due to the tendency to pull the workpiece upwards, causing tearing or chipping of the material. Up-cut milling is commonly used for roughing operations.

Climb Milling

Climb milling, also known as conventional milling, involves the cutter rotating in the same direction as the spindle movement on the machined surface. Climb milling offers higher precision and better surface finish as the cutter pushes the workpiece down, reducing the risk of tear-out and providing smoother cuts. This type of milling is suitable for finishing operations and achieving precise dimensions.

Furthermore, metal milling can also be classified based on construction, which includes:

- Front Milling: In front milling, the cutter machines surfaces on the frontal and cylindrical parts of the tool. This type of milling is effective when shaping complex geometries.

- Cylindrical Milling: Cylindrical milling refers to the machining of surfaces on the cylindrical part of the cutter. It is commonly used for drilling, contouring, and creating rounded corners.

- Miter Milling: Miter milling involves the use of milling cutters spread across the whole tool to create angles between 0 and 90 degrees. This type of milling is essential for precision angle cutting and joinery in woodworking and metalworking.

Understanding the different types of metal milling and machining techniques allows professionals to choose the most suitable approach based on the specific requirements of the project, such as material characteristics, desired surface finish, and dimensional accuracy.

| Type of Metal Milling | Kinetics | Construction |

|---|---|---|

| Up-Cut Milling | Opposite direction to spindle movement | N/A |

| Climb Milling | Same direction as spindle movement | N/A |

| Front Milling | N/A | Machining surfaces on frontal and cylindrical parts of the cutter |

| Cylindrical Milling | N/A | Machining surfaces on cylindrical part of the cutter |

| Miter Milling | N/A | Utilizing milling cutters spread on the whole tool to create angles between 0 and 90 degrees |

Key Parameters of Different Types of Metal Milling

Metal milling is a highly precise process that requires careful consideration of various key parameters to ensure optimal results. These parameters vary depending on the stage of machining and the specific type of metal alloy being milled. The four key parameters that play a crucial role in metal milling are:

- Milling Depth: The milling depth refers to the depth of cut made by the cutter in every spindle pass. It determines how much material will be removed at each step, influencing the overall time and efficiency of the milling process.

- Milling Width: The milling width is the width of cut made in subsequent passes after the initial depth has been achieved. It determines the width of the material that will be removed, allowing for the creation of precise and accurate shapes.

- Milling Speed: The milling speed refers to the rotational speed of the cutter. It directly affects the rate at which material is removed and can significantly impact the milling process’s efficiency and surface finish.

- Feed Velocity: The feed velocity is the movement velocity of the spindle or table. It determines how quickly the cutter moves across the material, affecting the overall milling time and the quality of the machined surface.

These key parameters must be carefully selected and adjusted to ensure the optimal utilization of the CNC milling machine and the specific cutters being used. Incorrect parameter settings can result in inadequate material removal, poor surface finish, and even damage to the milling machine or the workpiece being machined.

By understanding and fine-tuning these key parameters, machinists can achieve precise and accurate metal milling results, meeting the desired specifications for their projects.

| Parameter | Description |

|---|---|

| Milling Depth | The depth of cut made by the cutter in every spindle pass. |

| Milling Width | The width of cut made in subsequent passes after the initial depth has been achieved. |

| Milling Speed | The rotational speed of the cutter. |

| Feed Velocity | The movement velocity of the spindle or table. |

Traditional vs. Numerical Milling: What is CNC Metal Milling?

Traditional metal milling has been a staple in the manufacturing industry for decades. It involves the use of manual or automatic mills to shape metal parts with precision. While traditional milling offers high accuracy, it can be time-consuming and less efficient for large-scale production.

However, with the introduction of CNC (computer numerical control) milling, the industry experienced a revolutionary change. CNC metal milling is controlled by a computer, allowing for faster and highly automated milling processes. Although the initial programming can be time-consuming, CNC milling offers exceptional efficiency for large quantities of parts and ensures excellent precision in each production run.

CNC metal milling has become widely utilized in various industries, including aerospace, automotive, and medical. Its ability to deliver consistent and precise results has made it a preferred choice for many manufacturers. The use of advanced software and cutting-edge technology in CNC milling has elevated the overall efficiency and quality of metal machining.

Below is a comparison between traditional milling and CNC metal milling:

| Traditional Milling | CNC Metal Milling |

|---|---|

| Manual or automatic mills | Computer-controlled milling machines |

| High precision but time-consuming | Faster and automated milling processes |

| Less efficient for large-scale production | Highly efficient for large quantities of parts |

| Excellent precision and consistency |

Moving the manufacturing process from traditional milling to CNC metal milling brings numerous benefits in terms of efficiency, productivity, and cost-effectiveness. The ability to customize and automate the milling process according to specific requirements sets CNC metal milling apart as an innovative and effective method in metal machining.

With the continuous advancements in CNC technology, the future of metal milling looks promising. The integration of AI and machine learning in CNC systems opens up even more possibilities for improving productivity and enhancing the overall quality of machined parts.

Components of a Milling Machine

A milling machine is composed of several key components that work together to produce accurate and precise parts. These components include:

Spindle

The spindle is responsible for rotating the cutting tool. It provides the necessary power and speed to perform milling operations.

Table

The table is the work surface where the workpiece is placed. It provides stability and support during the milling process.

Ram

The ram is the vertical component that moves on the column and supports the milling head. It allows for vertical movement and positioning of the cutting tool.

Knee

The knee is the vertical component that supports the table. It allows for height adjustment, enabling precise positioning of the workpiece.

Base

The base is the foundation of the milling machine. It provides stability and support for the other components.

Milling Head

The milling head is the cutting tool that rotates on the spindle. It is responsible for removing material from the workpiece to create the desired shape.

Worktable

The worktable is where the workpiece is placed. It can be adjusted and secured to ensure precise positioning during milling operations.

Arbor Support

The arbor support supports the milling head and cutting tool. It provides stability and prevents excessive vibration during milling operations.

With these components working together, milling machines are capable of producing accurate and precise parts for various industries and applications.

Types of Milling Machines

Milling machines come in various types, each with its unique features and capabilities. Some common types include:

- Vertical Mills: These machines have a spindle that is perpendicular to the worktable. They are ideal for tasks that require cutting in the vertical direction.

- Horizontal Mills: In contrast to vertical mills, horizontal mills have a spindle that is parallel to the worktable. They are suitable for tasks that involve cutting in the horizontal direction.

- Knee Mills: Knee mills are equipped with a vertically adjustable worktable. This feature allows for greater flexibility and precision in machining operations.

- Bed Mills: Bed mills have a fixed bed that supports both the worktable and the spindle. They are known for their stability and rigidity, making them suitable for heavy-duty applications.

- Gantry Mills: Gantry mills feature a bridge-like structure that supports the worktable and the spindle. This design provides enhanced stability and allows for machining large workpieces.

- Universal Mills: Universal mills have a swiveling worktable that enables cutting at various angles. They are versatile machines that can perform a wide range of milling operations.

- CNC Milling Machines: CNC milling machines are computer-controlled machines that offer precise and complex milling capabilities. They are widely used in industries that require high accuracy and efficiency.

The choice of milling machine depends on specific requirements such as the size and complexity of the part and the precision and accuracy needed.

Milling Cutters

Milling cutters are essential cutting tools used in milling machines to remove material from a workpiece. They come in various types and shapes, each designed for specific milling tasks. The choice of milling cutter depends on factors such as the material being cut, the desired finish, and the complexity of the shape being cut.

Here are some common types of milling cutters:

- End Mills: These are cutting tools with cutting teeth on one end. They are suitable for plunging, slotting, and profiling operations.

- Face Mills: These cutting tools have cutting teeth on both the periphery and face. They are ideal for facing, shoulder milling, and roughing operations.

- Rotary Cutters: These cutters have teeth on the periphery. They are commonly used for roughing and finishing operations.

When selecting a milling cutter, it is important to consider the specific requirements of the milling operation. Factors such as the hardness of the material, the desired surface finish, and the tolerance levels will influence the choice of cutter. Additionally, the complexity of the shape being cut will determine whether a specialized cutter is needed.

| Milling Cutter Type | Application |

|---|---|

| End Mills | Plunging, slotting, profiling |

| Face Mills | Facing, shoulder milling, roughing |

| Rotary Cutters | Roughing, finishing |

Milling Operations

Milling machines are versatile tools used in various industries for shaping and machining different materials. They can perform a wide range of operations to achieve desired shapes and dimensions. Let’s explore some of the common milling operations.

Conventional Milling

In conventional milling, the cutting tool rotates in the same direction as the spindle, resulting in the material being cut in the same direction. This type of milling is suitable for roughing operations and removing a large volume of material quickly. However, it may result in a less smooth surface finish compared to other milling methods.

Climb Milling

In climb milling, the cutting tool rotates in the opposite direction of the spindle movement. This allows for smoother cutting and better surface finish. Climb milling is often preferred for finishing operations where precision and surface quality are crucial.

Peripheral Milling

Peripheral milling involves cutting the periphery of a workpiece to create a desired shape. This operation is commonly used for contouring, profiling, and creating intricate shapes with precision. By carefully controlling the movement of the workpiece and the cutting tool, milling machines can produce complex geometries effectively.

These milling operations play a vital role in various applications. They are used for cutting, drilling, boring, gear cutting, slotting, keyway cutting, and many other machining processes.

| Milling Operation | Description |

|---|---|

| Conventional Milling | Cutting in the same direction as the rotation of the cutter |

| Climb Milling | Cutting in the opposite direction of the cutter rotation |

| Peripheral Milling | Milling the periphery of a workpiece to create desired shape |

CNC Material Selection

Selecting the appropriate material for a CNC machining project is crucial to ensure optimal performance and desired outcomes. The choice of material depends on several factors, including environmental conditions, thermal exposure, conductivity/magnetic requirements, mechanical loading requirements, surface finish requirements, aesthetics, cost, weight, and the manufacturing method.

When it comes to CNC machining, there is a wide range of options available for both metals and plastics. Metals like stainless steel, aluminum, titanium, copper, and various steel alloys offer different properties that make them suitable for specific applications. These properties include strength, corrosion resistance, thermal conductivity, and electrical conductivity.

Plastics also play a significant role in CNC machining, offering characteristics such as chemical resistance, wear resistance, and heat resistance. Common plastic materials used in CNC machining include HDPE, nylon, PEEK, and polycarbonate. The selection of metal or plastic depends on the specific requirements of the application.

To help you visualize the options available, here is a table showcasing some popular materials used in CNC machining:

| Material | Properties | Applications |

|---|---|---|

| Stainless Steel | Strength, corrosion resistance | Aerospace, automotive, medical |

| Aluminum | Lightweight, strength, corrosion resistance | Aerospace, automotive, consumer products |

| Titanium | High strength-to-weight ratio | Aerospace, medical, industrial |

| Copper | Electrical conductivity, thermal conductivity | Electrical components, heat exchangers |

| HDPE | Chemical resistance, wear resistance | Containers, pipes, furniture |

| Nylon | High strength, flexibility | Gears, bearings, automotive components |

| PEEK | Heat resistance, chemical resistance | Aerospace, medical, automotive |

| Polycarbonate | Impact resistance, transparency | Prototypes, automotive, electronics |

By carefully considering the specific requirements and properties of different materials, you can make an informed decision during CNC material selection. This will ensure that your CNC machining project meets your expectations and delivers excellent results.

Stainless Steel in CNC Machining

Stainless steel is a highly versatile and widely used material in CNC machining due to its exceptional properties. It is valued for its strength, corrosion resistance, and suitability for harsh environments. In CNC machining, several stainless steel alloys are commonly employed, including 304, 316, 416, and 17-4 PH stainless steel. Each alloy has specific characteristics and alloying elements that make it suitable for different applications.

304 stainless steel is a low-carbon variation that offers excellent corrosion resistance and is commonly used in food processing equipment, chemical containers, and architectural applications.

316 stainless steel, also known as marine-grade stainless steel, is highly resistant to corrosive substances such as saltwater and chemicals. It is commonly used in marine equipment, medical devices, and pharmaceutical applications.

416 stainless steel is a free-machining grade that offers excellent machinability. It is often used in applications that require screws, bolts, and shafts.

17-4 PH stainless steel is a precipitation-hardening alloy that combines high strength and corrosion resistance. It is commonly used in aerospace components, automotive parts, and industrial equipment.

Stainless steel finds extensive use in various industries, including consumer products, industrial applications, aerospace, military, and automotive. Its durability and resistance to wear and tear make it an ideal choice for parts exposed to harsh conditions or corrosive environments. However, successful CNC machining of stainless steel requires proper tool selection, cutting speeds, and feeds to ensure high-quality results.

| Stainless Steel Alloy | Applications |

|---|---|

| 304 Stainless Steel | Food processing equipment, chemical containers, architectural applications |

| 316 Stainless Steel | Marine equipment, medical devices, pharmaceutical applications |

| 416 Stainless Steel | Screws, bolts, shafts |

| 17-4 PH Stainless Steel | Aerospace components, automotive parts, industrial equipment |

Aluminum in CNC Machining

Aluminum is a highly versatile material commonly used in CNC machining due to its exceptional properties. It is known for its excellent machinability, lightweight nature, impressive strength, and corrosion resistance. These qualities make it an ideal choice for a wide range of industries, including aerospace, automotive, medical, and consumer products.

One of the key advantages of aluminum in CNC machining is its cost-effectiveness compared to other metals. It offers a cost-efficient solution without compromising on quality. Moreover, aluminum is particularly suitable for applications where weight is a critical factor. Its lightweight nature allows for the production of components that are both strong and lightweight, making it advantageous for industries that prioritize fuel efficiency or weight reduction.

However, it is important to note that post-processing or finishing may be required after CNC machining of aluminum. This ensures that the final product meets the desired specifications and achieves the desired aesthetics. By carefully considering the specific requirements of the project and selecting the appropriate aluminum alloy, CNC machining can harness the full potential of this lightweight material, resulting in high-quality and cost-effective components.