A CNC machine is a computer-controlled machine that is used to cut and shape materials such as metal, wood, and plastic. The CNC machine is programmed to move the cutting tool in a specific pattern to create the desired shape. In order for the CNC machine to work, it must go through several steps.

The first step is to create a program for the CNC machine. This program is written in a computer language such as G-code or M-code. The program will tell the CNC machine what type of material to cut, how deep to cut, and what type of tool to use. Once the program is written, it is loaded into the CNC machine.

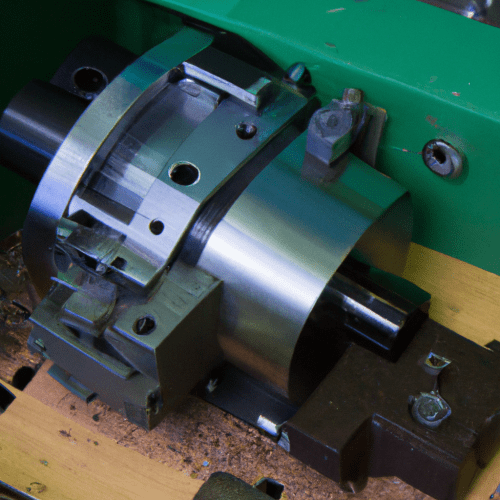

The next step is to set up the CNC machine. This includes attaching the cutting tool to the spindle, setting the cutting speed, and setting the feed rate. The cutting speed and feed rate will depend on the type of material being cut and the type of tool being used.

The third step is to load the material into the CNC machine. The material must be securely clamped to the bed of the machine so that it does not move during the cutting process.

The fourth step is to start the CNC machine. Once the machine is started, it will begin to move the cutting tool in the pattern specified in the program. The cutting tool will cut the material to the desired shape.

The fifth step is to monitor the CNC machine. The operator should watch the machine to make sure that it is cutting correctly and that the material is not being damaged.

The sixth step is to unload the material from the CNC machine. Once the material has been cut, it should be removed from the machine and inspected for accuracy.

The seventh step is to clean the CNC machine. This includes cleaning the cutting tool, the bed of the machine, and any other parts that may have been exposed to the cutting process.

What type of motor does a CNC machine use?

CNC machines typically use either a stepper motor or a servo motor. Stepper motors are the most common type of motor used in CNC machines, as they are relatively inexpensive and easy to control. They are also capable of producing high torque at low speeds, making them ideal for CNC applications. Servo motors are more expensive than stepper motors, but they offer higher accuracy and better speed control. They are also capable of producing higher torque at higher speeds, making them ideal for applications that require high precision and speed.

What is stepper motor in CNC machine?

A stepper motor is a type of electric motor used in CNC machines that converts digital pulses into mechanical motion. It is a brushless motor that is driven by a series of electromagnetic coils that are energized in a specific sequence. The motor is designed to move in discrete steps, or increments, in response to the digital pulses. This allows for precise control of the motor’s position and speed. Stepper motors are used in CNC machines to control the movement of the cutting tool, as well as other components such as spindles, feeders, and coolant pumps. They are also used in robotics, 3D printers, and other automated systems. Stepper motors are typically more reliable and accurate than other types of motors, and they are relatively inexpensive.

How many motors are used in CNC machine?

The number of motors used in a CNC machine depends on the type of machine and the complexity of the operations it is designed to perform. Generally speaking, CNC machines use at least two motors: one to drive the spindle, and one to drive the axes of motion. Some machines may also use additional motors to drive additional axes of motion, such as a fourth axis for rotary motion, or a fifth axis for tilting the spindle. Additionally, some machines may use servo motors to provide precise control over the motion of the axes. The exact number of motors used in a CNC machine will vary depending on the specific model and its intended use.

Which is better servo or stepper motors?

The answer to which motor is better, servo or stepper, depends on the application. Servo motors are better for applications that require precise positioning and speed control, while stepper motors are better for applications that require high torque and low speed.

Servo motors are typically used in applications that require precise positioning and speed control, such as robotics, CNC machines, and automated assembly lines. They are able to accurately control the position and speed of a load, and can be used to control the speed of a motor or the position of a load. Servo motors are also able to provide feedback to the controller, allowing for precise control of the motor.

Stepper motors are typically used in applications that require high torque and low speed, such as 3D printers and CNC machines. They are able to provide high torque at low speeds, and can be used to accurately control the position of a load. Stepper motors are also able to provide feedback to the controller, allowing for precise control of the motor.

Which type of motor is not used in CNC machine?

A CNC machine is a computer-controlled machine that is used to cut and shape materials such as wood, metal, and plastic. CNC stands for Computer Numerical Control, and it is a type of automation that is used to control the motion of machines. CNC machines are used in a variety of industries, including manufacturing, automotive, aerospace, and medical.

The type of motor used in a CNC machine depends on the type of machine and the application. Generally, CNC machines use either stepper motors or servo motors. Stepper motors are used for applications that require precise positioning and repeatability, such as milling and drilling. Servo motors are used for applications that require high speed and accuracy, such as lathes and routers.

The type of motor that is not used in CNC machines is a DC motor. DC motors are used in applications that require continuous rotation, such as fans and pumps. DC motors are not suitable for CNC machines because they do not provide the precise positioning and repeatability that is required for CNC applications.

What motor is used in the CNC lathe and why?

The motor used in a CNC lathe is typically a servo motor. Servo motors are used in CNC lathes because they are able to provide precise control over the speed and position of the spindle. Servo motors are also able to provide a high degree of accuracy and repeatability, which is essential for CNC lathes. Additionally, servo motors are able to provide a high degree of torque, which is necessary for the cutting and machining operations that are performed on a CNC lathe. Servo motors are also able to provide a high degree of reliability, which is important for a CNC lathe, as it needs to be able to operate for long periods of time without any issues. Finally, servo motors are relatively easy to program and control, which makes them ideal for use in CNC lathes.

What is a servo motor CNC?

A servo motor CNC (Computer Numerical Control) is a type of motorized system used to control the motion of a machine or device. It is a type of motorized system that uses a computer to control the motion of a machine or device. The servo motor CNC system is composed of a controller, a motor, and a drive system. The controller is the main component of the system and is responsible for controlling the motion of the motor. The motor is the actual device that moves the machine or device, and the drive system is responsible for providing the power to the motor.

The servo motor CNC system is used in a variety of applications, such as robotics, manufacturing, and automation. It is used to control the motion of a machine or device in a precise and repeatable manner. The servo motor CNC system is capable of controlling the motion of a machine or device in a variety of ways, such as linear, rotary, and circular motion.

What is the use of servo motor in CNC machine?

A servo motor is an essential component of a CNC (Computer Numerical Control) machine. It is used to control the motion of the machine, allowing it to accurately move in a precise manner. The servo motor is connected to the CNC machine’s control system, which is programmed to move the motor in a specific direction and at a specific speed. The servo motor is responsible for controlling the speed and direction of the machine, as well as the accuracy of the movement.

The servo motor is typically connected to a drive system, which is responsible for providing the power to the motor. This drive system is usually a stepper motor, which is capable of providing precise control over the speed and direction of the motor. The servo motor is then connected to the CNC machine’s control system, which is programmed to move the motor in a specific direction and at a specific speed.

Where and how a stepper motor is used in CNC machine?

A stepper motor is an electromechanical device used in CNC machines to convert electrical pulses into mechanical motion. It is a type of motor that moves in discrete steps, or steps, rather than continuously. Stepper motors are used in CNC machines to control the movement of the machine’s axes. They are used to move the cutting tool along the X, Y, and Z axes, as well as to rotate the spindle. Stepper motors are also used to control the speed and direction of the cutting tool.

The stepper motor is connected to the CNC machine’s control system, which sends electrical pulses to the motor. The motor then converts these pulses into mechanical motion, moving the cutting tool along the desired axis. The number of pulses sent to the motor determines the speed and direction of the cutting tool. The control system can also be programmed to move the cutting tool in a specific pattern, such as a circle or a square.