When it comes to choosing the right drill bit for carbide, there are a few factors to consider. First, you need to determine the type of carbide you are working with. Carbide is a hard material that is used in a variety of applications, such as cutting tools, abrasives, and wear-resistant parts. Depending on the type of carbide you are working with, you may need a different type of drill bit.

For general purpose drilling, a cobalt or titanium-coated high-speed steel (HSS) drill bit is usually the best choice. These drill bits are designed to cut through hard materials like carbide and are available in a variety of sizes and shapes. If you are drilling through a thicker piece of carbide, you may need a carbide-tipped drill bit. These drill bits are made from a combination of tungsten carbide and cobalt, and they are designed to cut through even the toughest materials.

How do I choose the right drill bit?

Choosing the right drill bit for a particular job is an important part of any DIY project. The type of drill bit you need will depend on the material you are drilling into, the size of the hole you need to make, and the type of drill you are using.

When selecting a drill bit, the most important factor to consider is the material you are drilling into. Different materials require different types of drill bits. For example, a drill bit designed for drilling into metal will not work for drilling into wood. Additionally, some materials require special drill bits, such as masonry drill bits for drilling into concrete or brick.

The size of the hole you need to make is also important when selecting a drill bit. Drill bits come in a variety of sizes, from very small to very large. It is important to select a drill bit that is the right size for the job. If the drill bit is too small, it will not be able to make the hole you need. If the drill bit is too large, it may cause damage to the material you are drilling into.

Can you drill metal with carbide?

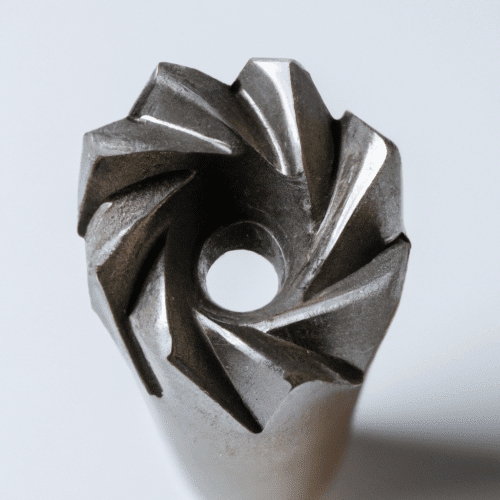

Yes, you can drill metal with carbide. Carbide is a type of material that is made up of a combination of carbon and other hard materials, such as tungsten, titanium, or tantalum. It is extremely hard and durable, making it an ideal material for drilling metal. Carbide drill bits are designed to be used on harder materials, such as stainless steel, cast iron, and other metals. They are also capable of drilling through softer materials, such as aluminum and brass.

When drilling metal with carbide, it is important to use the correct drill bit for the job. Carbide drill bits come in a variety of sizes and shapes, so it is important to select the right one for the job. It is also important to use the correct speed and pressure when drilling with carbide. Too much pressure can cause the drill bit to break, while too little pressure can cause the drill bit to slip and not cut properly.

Are carbide bits worth it?

Carbide bits are a type of cutting tool made from a combination of tungsten carbide and cobalt. They are known for their durability and strength, making them a popular choice for many industrial and commercial applications. Carbide bits are more expensive than traditional steel bits, but they are worth the extra cost due to their superior performance. Carbide bits are able to cut through harder materials than steel bits, and they can also be used to drill through materials that would otherwise be too hard for steel bits. Additionally, carbide bits are more resistant to wear and tear, meaning they will last longer than steel bits. They also produce a cleaner cut, which is important for precision work. In summary, carbide bits are worth the extra cost due to their superior performance and durability. They are ideal for cutting through harder materials and for precision work, and they will last longer than steel bits.

What is harder titanium or carbide?

Titanium and carbide are both incredibly hard materials, and it is difficult to definitively say which is harder. Titanium is a strong, lightweight metal that is used in a variety of applications, including aerospace and medical implants. It is highly resistant to corrosion and has a high strength-to-weight ratio. Carbide is a compound made up of carbon and other elements, such as tungsten, titanium, or tantalum. It is extremely hard and is used in a variety of industrial applications, such as cutting tools and wear-resistant coatings.

When comparing the hardness of titanium and carbide, it is important to consider the type of hardness being measured. There are two types of hardness: scratch hardness and indentation hardness. Scratch hardness measures the ability of a material to resist scratching or abrasion, while indentation hardness measures the ability of a material to resist indentation or penetration.

When it comes to scratch hardness, titanium is generally considered to be harder than carbide. This is because titanium has a higher resistance to abrasion than carbide.

Can tungsten be drilled?

Yes, tungsten can be drilled. Tungsten is a very hard metal, so it requires special tools and techniques to drill it. The most common way to drill tungsten is to use a diamond-tipped drill bit. This type of bit is designed to cut through hard materials like tungsten. It is important to use a drill bit that is specifically designed for tungsten, as regular drill bits will not be able to cut through the metal. When drilling tungsten, it is important to use a slow speed and plenty of lubrication. This will help to reduce the amount of heat generated by the drill bit and will also help to prevent the bit from becoming dull. It is also important to use a drill press when drilling tungsten, as this will help to ensure that the hole is drilled straight and even.

Is tungsten a carbide?

Tungsten is a chemical element with the symbol W and atomic number 74. It is a grayish-white metal that is extremely hard and dense, and it is the heaviest of all metals. Tungsten is often alloyed with other metals to form a variety of materials with different properties. Tungsten carbide is a compound of tungsten and carbon, and it is one of the hardest materials known to man. It is used in a variety of industrial applications, such as cutting tools, drill bits, and armor-piercing rounds. Tungsten carbide is formed by combining tungsten and carbon at very high temperatures, usually in a vacuum. The resulting material is extremely hard and resistant to wear and corrosion. It is also used in jewelry, as it is very durable and can be polished to a high shine.

What can cut tungsten carbide?

Tungsten carbide is a very hard material, making it difficult to cut with conventional tools. It is often used in industrial applications such as mining, construction, and metalworking. The most common way to cut tungsten carbide is with a diamond-tipped saw blade. Diamond blades are specifically designed to cut through hard materials like tungsten carbide. They are available in a variety of sizes and shapes, so you can choose the one that best fits your needs. Another option is to use a diamond grinding wheel. This is a specialized tool that uses diamond-coated abrasive particles to grind away the material. It is often used to shape and finish tungsten carbide components. A third option is to use a laser cutting machine. Laser cutting machines use a focused beam of light to cut through the material. This is a very precise method of cutting and is often used for intricate shapes and designs.

What’s the difference between tungsten and tungsten carbide?

Tungsten and tungsten carbide are both materials that are used in a variety of industrial and commercial applications. Tungsten is a naturally occurring element that is found in the Earth’s crust. It is a grayish-white metal that is extremely hard and has a high melting point. Tungsten is often used in the production of cutting tools, such as drill bits and saw blades, as well as in the production of electrical components and light bulbs.

Tungsten carbide, on the other hand, is a man-made material that is created by combining tungsten with carbon. It is an extremely hard material that is often used in the production of cutting tools, such as drill bits and saw blades, as well as in the production of jewelry and other decorative items. Tungsten carbide is also used in the production of industrial components, such as bearings and valves.