CNC machining services are extensively utilized across various industries, with aerospace, automotive, medical, electronics, and defense sectors leading the way. The aerospace industry relies heavily on CNC machining for producing complex, high-precision components for aircraft and spacecraft, ensuring optimal performance and safety.

Automotive manufacturers employ CNC technology to create engine parts, transmission components, and custom vehicle accessories with exceptional accuracy. In the medical field, CNC machining is crucial for fabricating intricate surgical instruments, implants, and prosthetics that require extreme precision and biocompatibility. The electronics industry benefits from CNC machining in the production of circuit boards, heat sinks, and custom enclosures for electronic devices.

Defense contractors use CNC services to manufacture specialized equipment, weapon components, and military vehicle parts that meet strict specifications. Other industries such as energy, robotics, and consumer goods also leverage CNC machining for creating prototypes, molds, and production parts with tight tolerances and consistent quality. The versatility, accuracy, and efficiency of CNC machining make it an indispensable technology across these diverse sectors, enabling the production of complex components that meet stringent industry standards and performance requirements.

- The manufacturing industries, such as the automotive industry, aerospace industry, medical industry, woodworking industry, metal fabrication industry, industrial machinery industry, technology industry, and engineering industry, heavily rely on CNC machining.

- CNC machining allows these industries to produce a wide range of products, from automotive components and aircraft parts to medical devices and custom machinery.

- CNC machining offers precise and high-quality production, meeting the specific requirements of each industry.

- Industries that utilize CNC machining benefit from its versatility, rapid prototyping capabilities, and the ability to work with various materials.

- CNC machining plays a crucial role in ensuring the efficiency, safety, and reliability of products across different sectors.

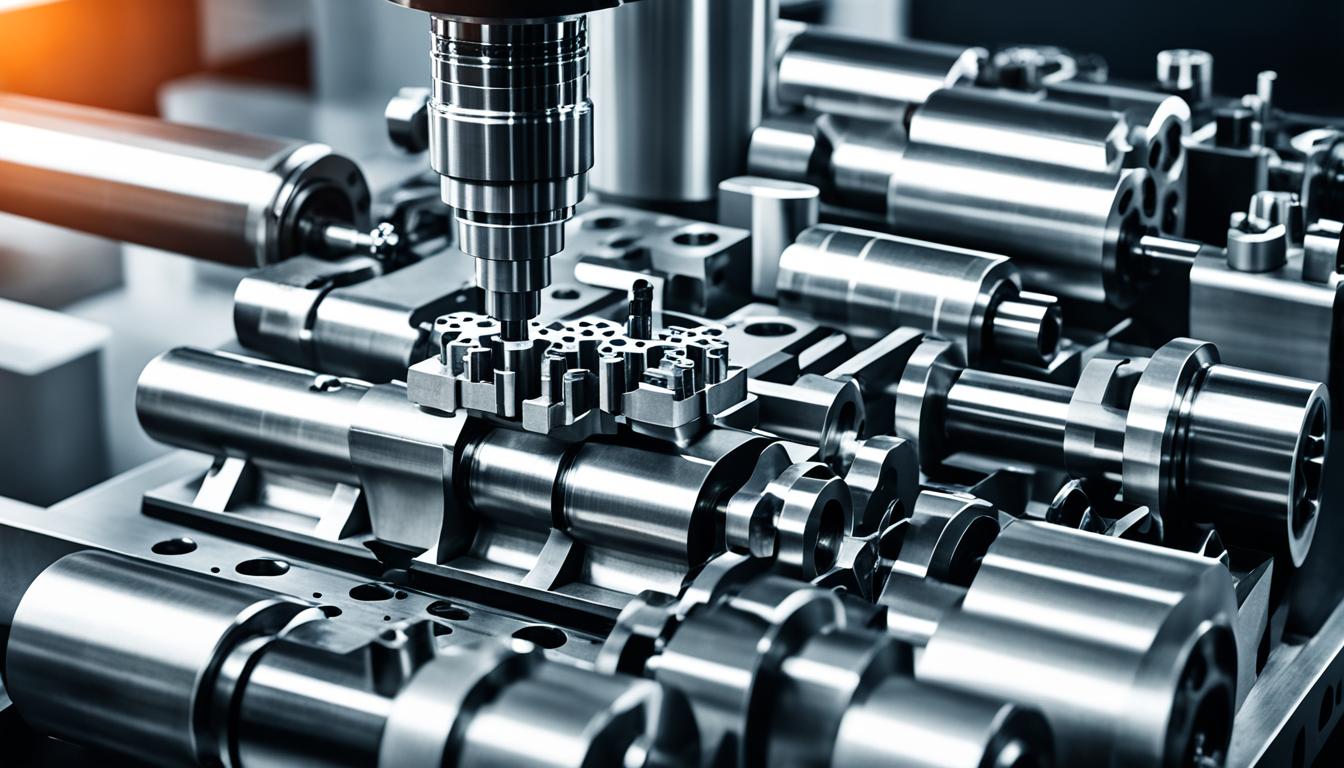

How CNC Machining Works

CNC machining is a process that utilizes computer software to guide machines in transforming a virtual design into a tangible, three-dimensional product. This process, known as subtractive manufacturing, involves starting with a block of material and using machines to cut away excess material to create the desired design.

Computer programming plays a crucial role in ensuring accuracy and precision throughout the CNC machining process. It begins with the creation of a design using computer-aided design (CAD) software. CAD software allows designers to create virtually any object, providing flexibility and freedom in design creation.

The design is then manipulated with computer-aided manufacturing (CAM) software to convert it into a format that the CNC machine can understand. CAM software optimizes the design for manufacturing, taking into account the capabilities of the CNC machine and the desired outcome.

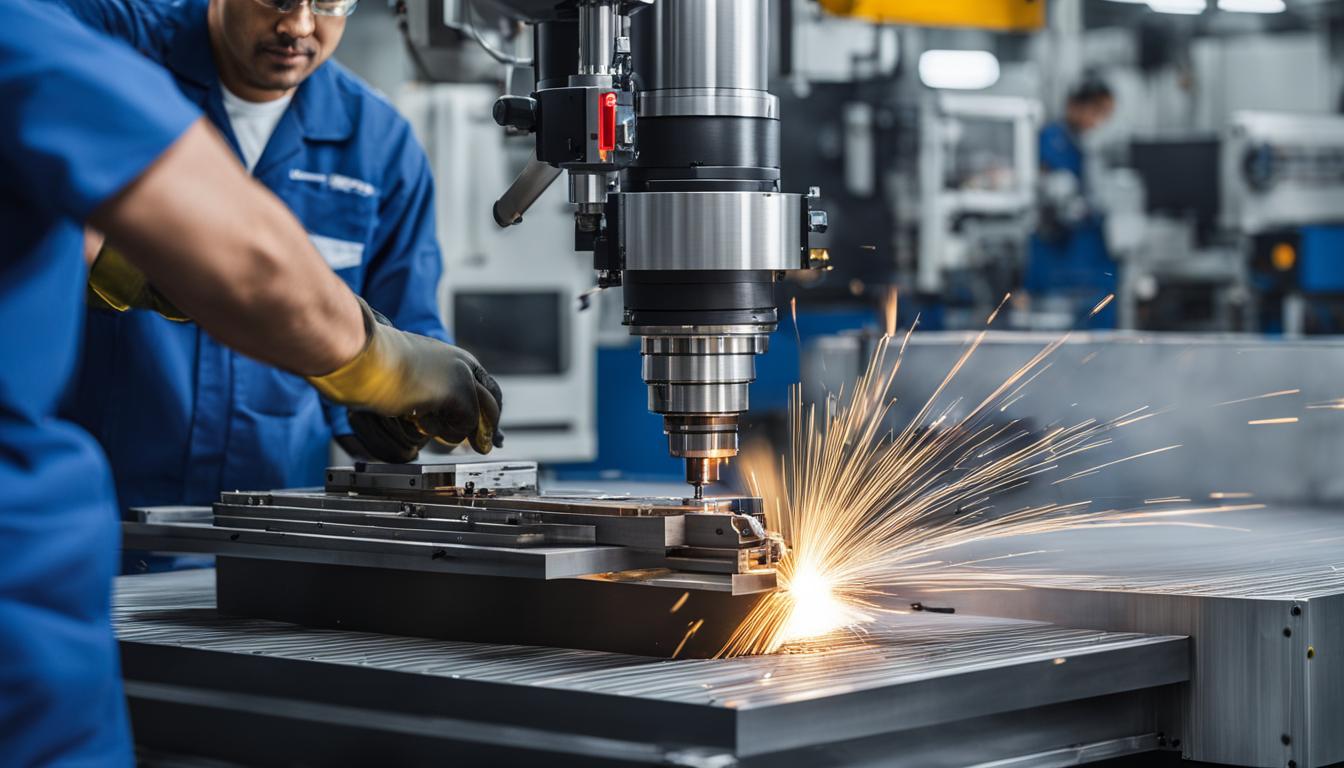

After the design is prepared, machinists set up the CNC machine with the necessary tools and materials. The CNC program, created using the CAD and CAM software, guides the machine in executing the desired design.

The subtractive manufacturing process begins as the CNC machine starts removing material from the block, shaping it according to the virtual design. The machine uses various cutting tools, such as drills, end mills, and lathes, to precisely shape the product.

Although CNC machining is highly precise, certain finishing touches may require manual intervention. This can include polishing, deburring, or other manual processes to achieve the desired surface finish and appearance.

Overall, CNC machining combines virtual design, subtractive manufacturing, computer programming, and finishing touches to create high-precision, custom parts with efficiency and accuracy.

CNC Machinery Capabilities

CNC machines offer a wide range of capabilities and are capable of producing various product designs. Their versatility makes them suitable for a variety of industries and applications. Here are some of the key capabilities of CNC machinery:

- Precision Machining: CNC machining is recognized for its ability to achieve high precision and consistent quality production, even at high volumes. This ensures that parts meet the exact specifications required.

- Prototyping: CNC machines enable rapid prototyping, allowing machinists to quickly produce sample products for testing and refinement. This speeds up the product development process and ensures that the final product meets the desired functionality.

- Versatile Manufacturing: CNC machining offers versatility in manufacturing as it can work with a wide range of materials, including metals, plastics, and composites. This flexibility allows for the production of parts with precise specifications for different industries.

- Materials: CNC machines can handle both standard shapes and objects with tapers and compound contours. This capability allows for the creation of complex designs and shapes with ease.

- Milling: Milling is a type of CNC machining process where the tools rotate around the workpiece, cutting and shaping the material to create the desired shape and design.

- Screw Machining: Screw machining is a specialized form of CNC machining that requires expert setup. It is commonly used for producing precise small parts with high accuracy and efficiency.

- Machine Turning: Machine turning, similar to a lathe, enables mass production of customized parts. It is widely employed in industries that require high volume production with consistent quality.

Overall, CNC machinery’s capabilities make it an indispensable tool in precision manufacturing, prototyping, and versatile production processes.

Advantages of CNC Machinery Capabilities

“The precision and versatility of CNC machinery make it a crucial asset for various industries. Its ability to consistently produce high-quality parts with tight tolerances and complex designs empowers manufacturers to deliver cutting-edge products.”

Medical Industry

The medical industry relies heavily on CNC machining to produce custom and precision parts. With the increasing demand for medical devices and equipment, CNC machining is essential for meeting the high volumes and precision requirements of this industry. From implants and MRI machines to orthotic devices and electrical parts, CNC machining plays a crucial role in ensuring the availability of essential medical supplies.

The production of custom parts is particularly important in the medical field, as each patient’s needs may vary. CNC machining allows for the rapid production of customized parts, ensuring they meet the specific requirements of healthcare professionals and patients. The ability to create precise parts with tight tolerances is critical in the development of medical instruments and devices that enhance patient care and improve treatment outcomes.

The Importance of CNC Machining in the Medical Industry

The medical industry relies on CNC machining for a wide range of applications, including:

- Implants: CNC machining is used to create custom-made implants that match the unique anatomical requirements of patients. These implants are designed to be biocompatible and provide optimal functionality.

- MRI Machines: CNC machining is instrumental in the production of MRI machine components, ensuring the accuracy and reliability of these medical imaging devices.

- Orthotic Devices: CNC machining is used to create orthotic devices, such as custom-fit braces and supports, that aid in the rehabilitation and recovery of patients.

- Electrical Parts: CNC machining is utilized in the production of electrical parts for medical equipment, ensuring precise functionality and safety.

- Customized Sterile Packaging: CNC machining is involved in the manufacturing of customized sterile packaging solutions to protect and preserve medical devices and instruments.

- Medical Instruments: CNC machining is integral to the production of high-quality medical instruments, including surgical tools, implants, and diagnostic devices.

- FDA-Approved Products: CNC machining enables the production of FDA-approved products that meet strict regulatory standards for safety and effectiveness.

The medical industry relies on CNC machining not only for the production of essential medical supplies but also for the development of innovative solutions that improve patient care. Through the utilization of CNC machining, the medical industry can ensure the availability of customized and high-quality products that meet the diverse needs of healthcare professionals and patients alike.

Aerospace Industry

The aerospace industry is known for its stringent precision requirements and tight tolerances. With its applications involving critical functions and safety, high accuracy is of utmost importance. CNC machining plays a vital role in meeting the precision demands of the aerospace industry, enabling the production of intricate and accurate components.

CNC machines are capable of achieving tight tolerances as small as 0.0001 inches, ensuring the meticulous production of aerospace parts. These components include aircraft components, such as antenae, airfoils, bushings, and landing gear, which require precise manufacturing for optimal performance and safety.

The aerospace industry heavily relies on CNC machining to ensure the reliability and integrity of its products. Even the smallest deviation from the required specifications can have significant consequences, making precise CNC machining indispensable in this sector.

Transportation Industry

The transportation industry, particularly the automotive industry, is a key player in the manufacturing sector. With high demand for vehicles, the transportation industry needs efficient processes to meet the required manufacturing rates. CNC machining proves to be a valuable asset in this industry, enabling the production of precision parts with utmost accuracy and consistency.

The automotive industry relies heavily on CNC machining, also known as CNC auto, to create specific parts that conform to the exact specifications. CNC machines are capable of producing high-quality automotive components round the clock, ensuring continuous production with minimal deviations. This level of production efficiency is vital in meeting the demands of the transportation industry’s dynamic market.

CNC machining provides the automotive industry with high-speed manufacturing machines that help optimize production efficiency. These machines can operate at exceptional speeds, allowing for the rapid production of automotive components without compromising precision and quality. By leveraging CNC technology, the transportation industry attains the necessary production rates while maintaining high product standards.

With CNC machining’s ability to produce precision parts efficiently, the transportation industry benefits from improved manufacturing processes, ensuring the efficiency and quality of its products.

Other Industries Utilizing CNC Machining

In addition to the automotive, aerospace, medical, and transportation industries, CNC machining is widely adopted by other sectors that require precise parts and high volume production. The oil and gas industry heavily relies on CNC machining to manufacture critical components that demand exceptional precision and use unique materials.

The robotic industry leverages CNC machining to produce custom parts with precision and quick turnaround times. By utilizing advanced manufacturing technology, CNC machines enable robotic manufacturers to create intricate and durable components that meet their specific requirements.

The electronics industry benefits greatly from CNC machining’s efficiency and accuracy in manufacturing complex and high-quality products. CNC machines enable electronics manufacturers to produce intricate circuit boards, precise connectors, and other electronic components with high precision and repeatability.

The marine industry also relies on CNC machining to create precise parts for ships and marine equipment. CNC manufacturing ensures the production of high-quality components that meet the stringent requirements of the marine industry, including durability, corrosion resistance, and accurate specifications.

With its proven capabilities in precise part manufacturing and advanced manufacturing technology, CNC machining has become an integral part of various industries, including oil and gas, robotics, electronics, and marine. This versatile manufacturing process supports high volume production while maintaining the precision and quality demanded by these industries.