When it comes to milling, the side you should mill on depends on the type of material you are working with and the type of milling you are doing. Generally, the side you should mill on is the side that is most stable and will provide the most accurate results.

For example, when milling aluminum, it is best to mill on the side that has the most flat surface. This will help to ensure that the milling process is as accurate as possible. Additionally, when milling steel, it is best to mill on the side that has the least amount of surface irregularities. This will help to ensure that the milling process is as precise as possible.

When milling wood, it is best to mill on the side that has the most grain. This will help to ensure that the milling process is as accurate as possible. Additionally, when milling plastic, it is best to mill on the side that has the least amount of surface irregularities. This will help to ensure that the milling process is as precise as possible.

In general, it is important to consider the type of material you are working with and the type of milling you are doing when deciding which side to mill on. This will help to ensure that the milling process is as accurate and precise as possible.

Which direction should an end mill spin?

An end mill is a type of cutting tool used in milling operations, which is typically used to cut and shape materials such as metal, wood, and plastic. The direction in which an end mill should spin depends on the type of material being cut and the type of end mill being used. Generally, end mills should spin in a clockwise direction when cutting materials such as metal, and in a counterclockwise direction when cutting materials such as wood and plastic.

When using an end mill, it is important to ensure that the cutting tool is spinning in the correct direction. If the end mill is spinning in the wrong direction, it can cause the material to be cut unevenly, resulting in a poor finish. Additionally, spinning the end mill in the wrong direction can cause the cutting tool to become damaged or even break.

When using an end mill, it is also important to ensure that the cutting speed is appropriate for the material being cut. If the cutting speed is too slow, the end mill may not cut the material properly, resulting in a poor finish.

Which way is climb milling?

Climb milling is a type of milling process in which the direction of the cut is reversed from the conventional milling process. In conventional milling, the cutter rotates against the direction of the feed, while in climb milling, the cutter rotates with the feed. This type of milling is beneficial because it reduces cutting forces, which can lead to improved surface finish, reduced tool wear, and increased tool life. Additionally, climb milling can reduce the amount of power required to perform the cut, as well as reduce the amount of vibration and chatter that can occur during the cutting process. The main disadvantage of climb milling is that it can cause the workpiece to move in the opposite direction of the cutter, which can lead to inaccurate cuts. Therefore, it is important to use a steady feed rate and to ensure that the workpiece is securely clamped in place before beginning the cut.

Which milling direction produces the best surface finish?

The best milling direction for producing a good surface finish depends on the type of material being machined, the type of milling cutter being used, and the desired surface finish. Generally, milling in the direction of the cutter rotation produces the best surface finish. This is because the cutting edges of the milling cutter are moving in the same direction as the material being machined, which reduces the amount of material being pushed away from the cutting edges. This results in a smoother surface finish.

When milling in the opposite direction of the cutter rotation, the cutting edges of the milling cutter are pushing the material away from the cutting edges, which can cause a rougher surface finish. Additionally, when milling in the opposite direction of the cutter rotation, the cutting edges of the milling cutter are more likely to cause chatter, which can also result in a rougher surface finish.

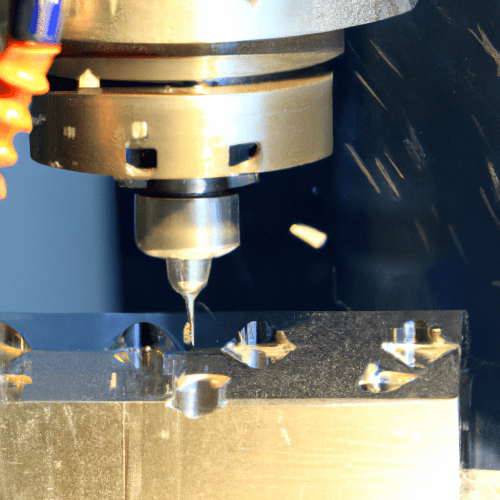

Do end mills cut on the side?

Yes, end mills can cut on the side. End mills are a type of cutting tool used in milling machines to remove material from a workpiece. They are typically made of tungsten carbide or high-speed steel and have a variety of cutting edges on the end and sides. The cutting edges on the sides of an end mill are known as flutes, and they are used to cut slots, grooves, and other features into the workpiece. End mills can be used to cut on the side of a workpiece by using the flutes to create a shallow cut. This type of cut is known as a side milling operation and is used to create a flat surface or to create a slot or groove in the workpiece. End mills can also be used to cut on the side of a workpiece by using the flutes to create a deeper cut. This type of cut is known as a plunge cut and is used to create a pocket or a hole in the workpiece.

Which is the best depth of cut for better surface finish?

The best depth of cut for better surface finish depends on a variety of factors, including the type of material being cut, the type of cutting tool being used, the cutting speed, and the feed rate. Generally speaking, the shallower the depth of cut, the better the surface finish. This is because a shallow depth of cut reduces the amount of material being removed, which reduces the amount of heat generated and the amount of vibration that occurs during the cutting process. Additionally, a shallow depth of cut reduces the amount of time the cutting tool is in contact with the material, which reduces the amount of wear and tear on the cutting tool.

When selecting the best depth of cut for better surface finish, it is important to consider the type of material being cut. For example, softer materials such as aluminum and brass require a shallower depth of cut than harder materials such as steel. Additionally, the type of cutting tool being used can also affect the best depth of cut. For example, a high-speed steel (HSS) tool requires a shallower depth of cut than a carbide tool.

Which of the following has the largest effect on the tool life?

Tool life is the length of time a tool can be used before it needs to be replaced or sharpened. The factors that have the largest effect on tool life are the material being cut, the cutting speed, the feed rate, the depth of cut, the cutting fluid, and the tool geometry.

Material: The material being cut has a large effect on tool life because different materials require different cutting speeds and depths of cut. Harder materials require slower cutting speeds and shallower depths of cut, while softer materials require faster cutting speeds and deeper depths of cut.

Cutting Speed: The cutting speed has a large effect on tool life because it determines how quickly the tool is cutting the material. If the cutting speed is too high, the tool will wear out quickly, while if the cutting speed is too low, the tool will take longer to cut the material.

Feed Rate: The feed rate has a large effect on tool life because it determines how quickly the material is being fed into the cutting tool.

What is the unit of cutting speed?

The unit of cutting speed is typically expressed in terms of surface feet per minute (SFM). SFM is a measure of the speed at which a cutting tool, such as a drill bit, moves across the surface of a material being cut. It is calculated by multiplying the rotational speed of the tool in revolutions per minute (RPM) by the circumference of the tool’s cutting edge. For example, if a drill bit is rotating at 10,000 RPM and has a cutting edge circumference of 0.25 inches, the cutting speed would be 2,500 SFM.

The cutting speed is an important factor in determining the quality of the finished product. If the cutting speed is too slow, the cutting tool will not be able to remove material quickly enough and the finished product will be of poor quality. On the other hand, if the cutting speed is too high, the cutting tool may overheat and cause damage to the material being cut. Therefore, it is important to select the correct cutting speed for the material being cut in order to achieve the desired results.