A center lathe, also known as an engine lathe, is a versatile machine used in various industries for machining operations. But why is it called a center lathe? Let’s explore the origin and meaning behind this term.

The name “center lathe” is derived from its design and functionality. The term “lathe” comes from the Old English word “lǽþ,” meaning tool or implement. The term “center” in center lathe refers to the two points, known as centers, which hold the workpiece in place during rotation.

The live center, located in the headstock, rotates with the workpiece, while the dead center, situated in the tailstock, does not rotate. This setup allows for precise operations on a wide range of materials.

- A center lathe gets its name from the two centers that hold the workpiece in place during rotation.

- The live center rotates with the workpiece, while the dead center remains stationary.

- Center lathes are used for precise machining operations on various materials.

- The term “center lathe” is interchangeable with “engine lathe.”

- Center lathes have a rich history and play a vital role in the manufacturing industry.

The Importance of Center Lathes in Manufacturing

Center lathes are a fundamental tool in the manufacturing industry, playing a crucial role in a wide range of machining operations. Whether it is turning, facing, drilling, knurling, or threading, center lathes are relied upon to produce high-quality and precise components. These versatile machines ensure concentric work is achieved, allowing for accurate transfer between different machining processes.

In addition to their primary role in lathe operations, center lathes also find application in various other equipment, such as dividing heads, cylindrical grinders, and tool and cutter grinders. This versatility makes them indispensable in the manufacturing world, ensuring that a diverse range of operations can be performed with efficiency and precision.

Center lathes have a significant impact on the overall quality of a finished product. By preserving concentricity throughout the manufacturing process, these machines allow for the production of parts with exceptional accuracy. This is particularly important in industries where precision is critical, such as aerospace, automotive, and medical device manufacturing.

Advantages of Center Lathes

Center lathes offer numerous advantages that contribute to their continued importance in the manufacturing sector. These advantages include:

- Versatility: Center lathes can perform a wide range of operations, making them suitable for various applications.

- High precision: These machines allow for the production of components with tight tolerances, ensuring the desired quality is achieved.

- Flexibility in production: Center lathes can accommodate both one-off creations and batch production, providing adaptability to different manufacturing needs.

- Simplicity and ease of use: Despite their complex capabilities, center lathes are relatively straightforward to operate, making them accessible to operators of different skill levels.

- Expandability: With the use of various attachments, such as steady rests and tool holders, the capabilities of center lathes can be expanded to meet specific production requirements.

With these advantages, center lathes continue to be a cornerstone of the manufacturing industry, ensuring high-quality and precise components are produced efficiently.

Table: Applications of Center Lathes in Various Industries

| Industry | Applications |

|---|---|

| Metalworking | Turning, facing, drilling, threading metal components |

| Woodworking | Woodturning, producing furniture pieces, decorative items |

| Glass-working | Shaping glass objects, creating artistic designs |

| Pottery | Molding clay, creating ceramic vessels and sculptures |

| Aerospace | Manufacturing aircraft components, engine parts |

| Automotive | Producing engine parts, gears, shafts |

As shown in the table above, center lathes find extensive applications in a variety of industries, ranging from metalworking and woodworking to aerospace and automotive manufacturing. Their ability to perform precise and diverse operations makes them indispensable tools in the production of a wide array of objects, from small components to large-scale structures.

The Evolution and Significance of Center Lathes

The center lathe, also known as the engine lathe, has a rich history and is considered one of the first complex tools developed in the field of manufacturing. Its name, “center lathe,” signifies the use of centers to hold the workpiece in place during rotation. The term “engine lathe” originated during the Industrial Revolution when the lathe was powered by steam engines. Despite changes in power sources, the name “engine lathe” has stuck and is synonymous with a center lathe.

Over the centuries, the center lathe has evolved while maintaining its basic principle. It has played a pioneering role in shaping the modern manufacturing world and is often referred to as the “Father of all Machines.” The center lathe is the bedrock of the manufacturing industry, producing parts for other machine tools and machines themselves. Its universal applicability and essential nature underscore its significance in various industries.

Center lathes have stood the test of time and continue to be vital in today’s manufacturing processes. From simple turning operations to more complex tasks like facing, drilling, knurling, and threading, center lathes offer versatility and precision. They serve as the foundation for creating a wide range of objects, including screws, candlesticks, gun barrels, musical instruments, and crankshafts, across industries like metalworking, woodturning, glass-working, and pottery shaping.

The Evolution of the Center Lathe

Throughout history, the center lathe has undergone significant advancements and refinements. From its early origins in ancient civilizations to the Industrial Revolution, the center lathe has continuously evolved to meet the growing demands of manufacturing.

In ancient times, lathes were operated manually and relied on human power to drive the cutting tool. As civilizations advanced, lathes became larger and incorporated more efficient mechanisms, such as foot pedals and treadles, to drive the workpiece. The introduction of water and steam power during the Industrial Revolution revolutionized the lathe, allowing for greater precision, speed, and productivity.

In the modern era, center lathes have become highly automated and equipped with advanced features like digital controls and computer numerical control (CNC) systems. These advancements have further enhanced the lathe’s accuracy, efficiency, and capabilities, making it an indispensable tool in the manufacturing world.

| Period | Key Developments |

|---|---|

| Ancient Times | Manual operation, foot-powered mechanisms |

| Industrial Revolution | Introduction of water and steam power |

| Modern Era | Automation, digital controls, CNC systems |

Advantages of Center Lathes

Center lathes, also known as central lathes, offer numerous advantages that make them indispensable in the manufacturing industry. These advantages contribute to their enduring popularity and continued use in a wide range of applications.

High Versatility

One of the key advantages of center lathes is their versatility. They can perform various operations such as turning, facing, drilling, knurling, and threading, making them suitable for a wide range of machining tasks. This versatility allows manufacturers to use center lathes for different projects and ensures efficient production.

Precision and Accuracy

Center lathes are designed to deliver high precision and accuracy in machining operations. The use of centers, which securely hold the workpiece during rotation, ensures consistent and precise results. This precision is crucial in industries where tight tolerances are required, such as aerospace and automotive manufacturing.

Flexibility for Production

Center lathes offer flexibility in production, accommodating both one-off creations and batch production. They can handle small-scale, custom projects as effectively as larger-scale production runs. This adaptability makes center lathes suitable for a wide range of manufacturing needs, from prototyping to mass production.

| Advantages of Center Lathes |

|---|

| Versatility |

| Precision and Accuracy |

| Flexibility for Production |

In conclusion, center lathes provide numerous advantages that make them essential tools in the manufacturing industry. Their versatility, precision, and flexibility contribute to their enduring importance and widespread use. Whether for small-scale projects or large-scale production, center lathes offer the precision and efficiency required for high-quality results.

The Relationship Between Center Lathes and Engine Lathes

The terms “center lathe” and “engine lathe” are often used interchangeably in the manufacturing industry. Both terms refer to the same type of lathe that holds the workpiece between two centers. The center lathe and engine lathe have a similar design, including a headstock, bed, carriage, tailstock, and other components. The use of the term “engine lathe” originated during the Industrial Revolution when these lathes were powered by steam engines. Despite changes in power sources, the name “engine lathe” has stuck and is synonymous with a center lathe.

The center lathe, also known as an engine lathe, is a versatile machine tool that can perform a variety of machining operations. These operations include turning, facing, drilling, knurling, and threading. Center lathes are highly valued for their ability to create precise and accurate workpieces. They are used in a wide range of industries, including automotive, aerospace, and manufacturing. Center lathes provide machinists with the flexibility to produce both one-off creations and batch productions. With the use of various attachments, they can adapt to different machining needs.

Overall, the relationship between center lathes and engine lathes is one of overlapping terminology and shared functionality. Regardless of the specific name used, these machines play a vital role in the manufacturing world by enabling the production of intricate and precise parts. The interchangeability of the terms “center lathe” and “engine lathe” showcases the historical evolution of this essential tool in the industry.

https://www.youtube.com/watch?v=dj64QvvbGXM

Comparison: Center Lathe vs. Engine Lathe

| Center Lathe | Engine Lathe |

|---|---|

| Refers to the same type of lathe | Refers to the same type of lathe |

| Used interchangeably with the term “engine lathe” | Used interchangeably with the term “center lathe” |

| Design includes headstock, bed, carriage, tailstock, and other components | Design includes headstock, bed, carriage, tailstock, and other components |

| Originated during the Industrial Revolution when powered by steam engines | Originated during the Industrial Revolution when powered by steam engines |

| Performs various machining operations like turning, facing, drilling, knurling, and threading | Performs various machining operations like turning, facing, drilling, knurling, and threading |

| Offers versatility and adaptability with the use of attachments | Offers versatility and adaptability with the use of attachments |

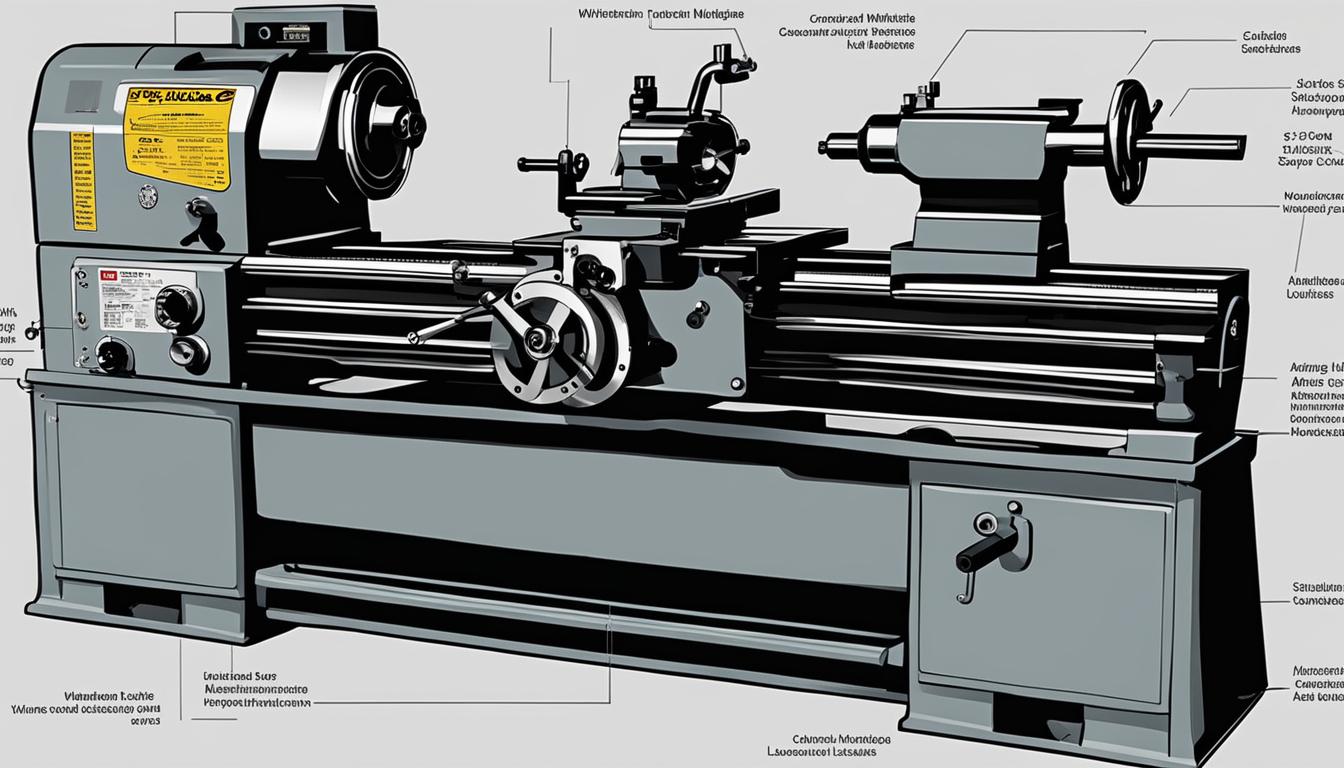

Components and Specifications of a Center Lathe

A center lathe is a complex machine consisting of various components that work together to perform precise machining operations. Understanding these components and their specifications is essential for manufacturers and machinists to make informed decisions and achieve the desired results.

Components of a Center Lathe

Here is an overview of the key components of a center lathe:

- Headstock: The headstock houses the main spindle, which rotates the workpiece. It also includes gears and the drive mechanism to control the spindle speed.

- Tailstock: The tailstock is located at the opposite end of the headstock and provides support to the other end of the workpiece. It is equipped with a dead center, which does not rotate.

- Bed: The bed is the base of the lathe that supports all the other components. It provides stability and precision during machining operations.

- Carriage: The carriage moves along the bed and carries the cutting tool. It can be manually operated or equipped with automatic feed mechanisms.

- Cross-slide: The cross-slide is mounted on the carriage and allows for lateral movement of the cutting tool. It enables precise positioning and depth of cut control.

- Compound Rest: The compound rest is positioned on top of the cross-slide and enables the cutting tool to be angled for taper turning operations.

- Tool Post: The tool post holds the cutting tool and allows for quick and easy tool changes. It can be adjusted for height and angular positioning.

Specifications of a Center Lathe

In addition to the components, the specifications of a center lathe play a crucial role in determining its capabilities. Here are some key specifications to consider:

| Specification | Description |

|---|---|

| Swing over Bed | The maximum diameter of the workpiece that can be accommodated on the lathe. |

| Distance Between Centers | The maximum length of the workpiece that can be held between the headstock and tailstock centers. |

| Spindle Speed Range | The range of speeds at which the spindle can rotate, allowing for different cutting operations. |

| Type of Drive | The method used to drive the spindle, such as belt drive or gear drive. |

| Horsepower | The power of the motor that drives the lathe, determining its cutting capacity. |

| Types of Tool Posts | The different types of tool post systems available for holding and adjusting cutting tools. |

| Bed Design | The shape and structure of the bed, which affects the rigidity and stability of the lathe. |

By understanding the components and specifications of a center lathe, manufacturers and machinists can choose the right machine for their specific needs and perform accurate and efficient machining operations.

Comparison with Other Types of Lathes

Center lathes are a type of lathe that can be distinguished from other types, such as speed lathes and CNC lathes. While speed lathes are simpler machines used for specific purposes like woodturning and polishing, center lathes offer greater versatility and complexity for various machining operations. The term “center lathe” is often used interchangeably with “engine lathe”, further highlighting the similarities between these types. CNC lathes, on the other hand, utilize computer numeric control for precise machining, allowing for automated and accurate production.

One notable distinction between center lathes and other types is their level of flexibility and adaptability. Center lathes can perform a range of operations like turning, facing, drilling, knurling, and threading, making them suitable for diverse machining needs. In comparison, speed lathes and CNC lathes may have more limited capabilities depending on their design and purpose.

Table:

| Types of Lathes | Distinguishing Features |

|---|---|

| Center Lathes | Offer versatility and can perform various operations |

| Speed Lathes | Simple machines used for woodturning and polishing |

| CNC Lathes | Utilize computer numeric control for precise machining |

Another notable comparison can be made between center lathes and turret lathes. While center lathes are generally more versatile and suitable for one-off creations and batch production, turret lathes are specialized for repetitive production processes. Turret lathes feature a turret tool post that allows for quick and automated tool changes, enhancing efficiency in high-volume production.

In summary, center lathes stand out as the go-to choice for general machining needs, offering flexibility, precision, and reliability. While other types of lathes have their own advantages and specialized applications, center lathes remain the preferred option for many manufacturing processes.

The Importance of the Center Lathe in the Manufacturing World

The center lathe holds a significant position in the manufacturing industry and is often referred to as the “Father of all Machines.” This title reflects the crucial role it plays in shaping the modern manufacturing world. Center lathes are responsible for producing essential parts used in a wide range of machines and equipment, from simple bolts to complex automotive and aircraft components. Their universal applicability and indispensable nature in manufacturing underscore their significance.

Center lathes have earned their reputation as the foundation of the manufacturing industry. They produce critical components necessary for other machine tools and machines themselves. Without the center lathe, the manufacturing process would be severely hindered, as it enables the creation of precise and accurate parts that form the backbone of various industries.

Similar to the milling machine, which is often referred to as the “Mother of all Machines,” the center lathe’s importance cannot be overstated. Together, these two machines provide the basis for creating a vast array of shapes and components used in countless industries. They have revolutionized manufacturing and remain indispensable tools in the hands of skilled machinists.

Advantages of Center Lathes:

- Versatility: Center lathes are capable of performing various operations, including turning, facing, drilling, knurling, and threading. This versatility allows for a wide range of manufacturing processes.

- High Precision: Center lathes offer exceptional precision, ensuring accuracy in the production of complex parts.

- Flexibility in Production: Whether producing one-off creations or batch production, center lathes provide the flexibility to meet diverse manufacturing needs.

- Simplicity and Ease of Use: Center lathes are designed to be user-friendly, allowing machinists to operate them with ease.

- Adaptability: With the use of various attachments, center lathes can be enhanced to expand their capabilities and cater to specific machining requirements.

The center lathe’s advantages, coupled with its pivotal role in manufacturing, make it an indispensable tool in the industry. Its ability to produce high-quality, precise parts has solidified its position as the “Father of all Machines,” shaping the world of manufacturing as we know it today.

The Material Choice for Lathe Centers

When it comes to lathe centers, the choice of material is crucial to ensure durability, accuracy, and optimal performance during machining operations. Lathe centers are typically made from hard materials such as high-speed steel (HSS) or tungsten carbide. These materials offer excellent wear resistance, allowing the centers to withstand the friction and forces exerted during cutting and turning processes. Their thermal stability is also essential to maintain the shape and size of the centers even under the heat generated by cutting forces.

High-speed steel (HSS) is a popular material choice for lathe centers due to its exceptional hardness and heat resistance. HSS centers can withstand high temperatures without losing their shape or strength, ensuring consistent and precise machining results. Tungsten carbide, on the other hand, is known for its extreme hardness and wear resistance. It is widely used in high-precision machining applications where the centers are subjected to heavy loads and prolonged use.

The choice of material for lathe centers depends on various factors, including the type of workpiece, machining conditions, desired accuracy, and tool longevity. It is essential to select the appropriate material based on the specific requirements of the machining operation. By choosing the right material for lathe centers, manufacturers can improve productivity, enhance machining accuracy, and extend the lifespan of their equipment.

Different Types of Lathe Centers

| Type | Material | Application |

|---|---|---|

| Dead Center | High-Speed Steel (HSS) | General-purpose machining |

| Live Center | High-Speed Steel (HSS) | Lathe turning operations |

| Interchangeable Center | Tungsten Carbide | Heavy-duty machining |

In addition to the material choice, lathe centers come in various types to suit different machining applications. The most common types include dead centers, live centers, and interchangeable centers. Dead centers do not rotate and are primarily used for supporting the workpiece during turning and facing operations. Live centers, on the other hand, rotate along with the workpiece, providing additional support and reducing friction. Interchangeable centers are designed for heavy-duty machining and can be easily replaced or interchanged when needed.

In conclusion, the material choice for lathe centers plays a crucial role in ensuring the durability, accuracy, and optimal performance of machining operations. High-speed steel (HSS) and tungsten carbide are commonly used materials due to their excellent wear resistance and thermal stability. By selecting the appropriate material and type of lathe centers, manufacturers can achieve superior machining results and maximize the lifespan of their equipment.

The Role of Accessories in Center Lathes

In the world of center lathes, accessories play a vital role in enhancing the functionality and versatility of these machines. These accessories enable machinists to mount workpieces securely and perform a wide range of machining operations with precision. Let’s explore some of the key accessories that are commonly used with center lathes.

Live Center

The live center is a crucial accessory located in the headstock of a center lathe. It rotates along with the workpiece, providing support and reducing vibration during machining operations. The live center features a pointed tip that engages with the workpiece, ensuring accurate rotation and alignment. This accessory is particularly useful when working with long and slender workpieces that require additional stability.

Dead Center

The dead center is another essential accessory found in the tailstock of a center lathe. Unlike the live center, the dead center remains stationary while the workpiece rotates. It provides stability and support to the workpiece during machining, allowing for precise and controlled cutting. The dead center typically has a flat or pointed tip, depending on the specific requirements of the workpiece and the machining operation.

Steady Rest

A steady rest is an accessory used to support long and slender workpieces during machining. It consists of a rigid frame with adjustable arms that can be positioned to hold the workpiece securely. The steady rest prevents deflection and vibration, ensuring consistent and accurate machining results. This accessory is particularly useful when working with materials that are prone to flexing, such as thin-walled tubes or rods.

Overall, these accessories significantly enhance the capabilities of center lathes, enabling machinists to achieve precise and reliable results in their machining operations. Whether it’s the live center providing rotational support, the dead center ensuring stability, or the steady rest preventing deflection, these accessories play a crucial role in maximizing the potential of center lathe machines.

Applications of Center Lathes

Center lathes play a vital role in various industries, making them indispensable tools in manufacturing processes. Whether it’s metalworking, woodturning, glass-working, or pottery shaping, center lathes are versatile machines that can handle a wide range of materials.

In the field of metal machining, center lathes are especially crucial. They excel in turning operations, where the workpiece is rotated while a cutting tool shapes it into the desired form. With their precision and versatility, center lathes are capable of producing an array of objects, from simple screws and candlesticks to complex gun barrels, musical instruments, and crankshafts.

But it’s not just metals that center lathes can handle. They are also used in machining various other materials such as wood, plastics, and ceramics. This wide range of applications makes center lathes essential for creating intricate and precise components across different industries.

Whether it’s shaping metal parts for machinery, creating decorative wooden pieces, or crafting delicate ceramic objects, center lathes are the go-to machines. Their ability to turn raw materials into finished products with accuracy and efficiency makes them invaluable in the manufacturing world. As the backbone of machining processes, center lathes continue to be crucial in the production of countless items we use in our daily lives.