The answer to the question of which is better, laser or CNC, depends on the specific application. Generally speaking, laser cutting is better for cutting thin materials such as paper, fabric, and thin plastics, while CNC machining is better for cutting thicker materials such as metals and hardwoods. Laser cutting is faster and more precise than CNC machining, but CNC machining is more versatile and can be used to create complex shapes and intricate details.

When it comes to cost, laser cutting is usually more expensive than CNC machining, but the cost of laser cutting can be offset by the fact that it is faster and more precise. CNC machining is usually more affordable, but it is slower and less precise than laser cutting.

In terms of safety, laser cutting is generally safer than CNC machining because it does not involve the use of sharp tools or hazardous materials. CNC machining, on the other hand, can involve the use of sharp tools and hazardous materials, so it is important to take safety precautions when using CNC machines.

Overall, the choice between laser and CNC depends on the specific application and the desired outcome. If speed and precision are the main considerations, then laser cutting is usually the better choice. If cost and versatility are the main considerations, then CNC machining is usually the better choice.

Can CNC cut metal?

Yes, CNC (Computer Numerical Control) machines can cut metal. CNC machines are automated milling devices that utilize a cutting tool that is programmed by a computer to rapidly remove material from a block of metal to create a desired shape. The cutting tool is usually a high-speed rotating cutting tool, such as a drill bit, end mill, or router bit. The cutting tool is guided by the computer-controlled motion of the CNC machine, which is programmed with a specific set of instructions. The instructions tell the machine how to move the cutting tool in order to create the desired shape.

CNC machines are used in a variety of industries, including automotive, aerospace, and medical, to create complex shapes and parts from metal. CNC machines are capable of cutting a wide variety of metals, including aluminum, steel, stainless steel, brass, and titanium. The type of metal being cut will determine the type of cutting tool and cutting speed that is used.

Can a CNC machine cut wood?

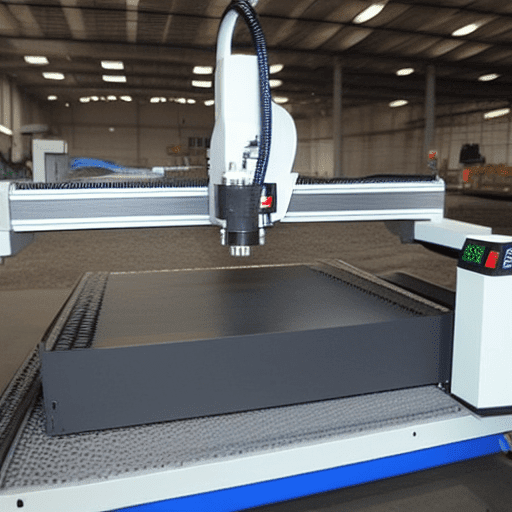

Yes, a CNC machine can cut wood. CNC stands for Computer Numerical Control, and it is a type of automated machine that is used to cut and shape materials such as wood, metal, plastic, and foam. CNC machines are programmed with a computer-aided design (CAD) software, which allows the user to input the desired shape and size of the material to be cut. The CNC machine then uses a cutting tool, such as a router, to cut the material according to the programmed instructions.

CNC machines are used in a variety of industries, including woodworking, metalworking, and plastics manufacturing. They are used to create a variety of products, from furniture to toys to musical instruments. CNC machines are also used to create intricate designs and patterns in wood, such as inlays and marquetry.

CNC machines are capable of cutting wood with precision and accuracy. The cutting tool is guided by the programmed instructions, and the cutting speed and depth can be adjusted to achieve the desired results.

Can a CNC machine cut paper?

Yes, a CNC machine can cut paper. CNC stands for Computer Numerical Control, and it is a type of automated machine that is used to cut and shape materials. CNC machines are typically used to cut and shape metals, plastics, and other hard materials, but they can also be used to cut paper.

Paper cutting with a CNC machine is done using a router bit, which is a type of cutting tool that is designed to cut through softer materials. The router bit is attached to the CNC machine and is used to cut the paper into the desired shape. The CNC machine is programmed with the desired shape and the router bit is used to cut the paper into that shape.

CNC machines are used in a variety of industries, including printing, packaging, and advertising. They are used to cut paper into shapes for packaging, labels, and other printed materials. CNC machines are also used to cut paper into intricate shapes for use in scrapbooking and other craft projects.

Can laser cutters engrave?

Yes, laser cutters can engrave. Laser engraving is a process that uses a laser beam to etch or mark an object. The laser beam is directed at the material to be engraved, which then vaporizes the material, leaving behind an engraved mark. Laser engraving is used to create intricate designs, logos, and text on a variety of materials, including metal, plastic, wood, and glass. Laser engraving is a precise and efficient way to create detailed designs and text on a variety of materials. Laser cutters are capable of engraving a wide range of materials, including metal, plastic, wood, and glass. The laser beam is directed at the material to be engraved, which then vaporizes the material, leaving behind an engraved mark. Laser engraving is used to create intricate designs, logos, and text on a variety of materials. The laser beam is focused and directed at the material to be engraved, which then vaporizes the material, leaving behind an engraved mark.

How thick can a laser cutter cut?

The thickness of material that a laser cutter can cut depends on the power of the laser, the material being cut, and the type of laser cutter being used. Generally, laser cutters are capable of cutting through materials up to 1/4 inch thick, although some laser cutters can cut through thicker materials. The power of the laser is the most important factor in determining the thickness of material that can be cut. The higher the power of the laser, the thicker the material that can be cut. The type of laser cutter also affects the thickness of material that can be cut. For example, CO2 laser cutters are capable of cutting through thicker materials than fiber laser cutters. Additionally, the type of material being cut also affects the thickness of material that can be cut. For example, some materials, such as wood, can be cut more easily than other materials, such as metal.

In conclusion, the thickness of material that a laser cutter can cut depends on the power of the laser, the type of laser cutter being used, and the type of material being cut.

What can a 5 watt laser cut?

A 5 watt laser cutter is a powerful tool that can be used to cut a variety of materials. It is capable of cutting through wood, acrylic, paper, cardboard, fabric, and even some metals. The thickness of the material that can be cut depends on the type of material and the wattage of the laser. Generally, a 5 watt laser can cut through materials up to 1/4 inch thick.

When cutting wood, the laser will create a smooth, clean cut with minimal charring. The laser can also be used to engrave designs into the wood. Acrylic can be cut with a 5 watt laser, but the edges may require some sanding to get a smooth finish. Paper and cardboard can be cut with a 5 watt laser, but the edges may be slightly charred. Fabric can be cut with a 5 watt laser, but the edges may require some trimming to get a clean finish.

Metals can also be cut with a 5 watt laser, but the wattage of the laser must be increased to achieve a clean cut.

Can you put a laser on a CNC router?

Yes, you can put a laser on a CNC router. A CNC router is a computer-controlled cutting machine used to cut a variety of materials, such as wood, plastic, metal, and foam. A laser is a device that emits a beam of light that is focused and concentrated into a small area. By combining a CNC router with a laser, you can create a powerful tool that can be used to cut and engrave a variety of materials.

The process of adding a laser to a CNC router is relatively simple. First, you will need to purchase a laser module that is compatible with your CNC router. Once you have the laser module, you will need to mount it to the router. This can be done by attaching the laser module to the router’s spindle or by using a mounting bracket. Once the laser module is mounted, you will need to connect it to the CNC router’s control system. This will allow the CNC router to control the laser’s power and speed.