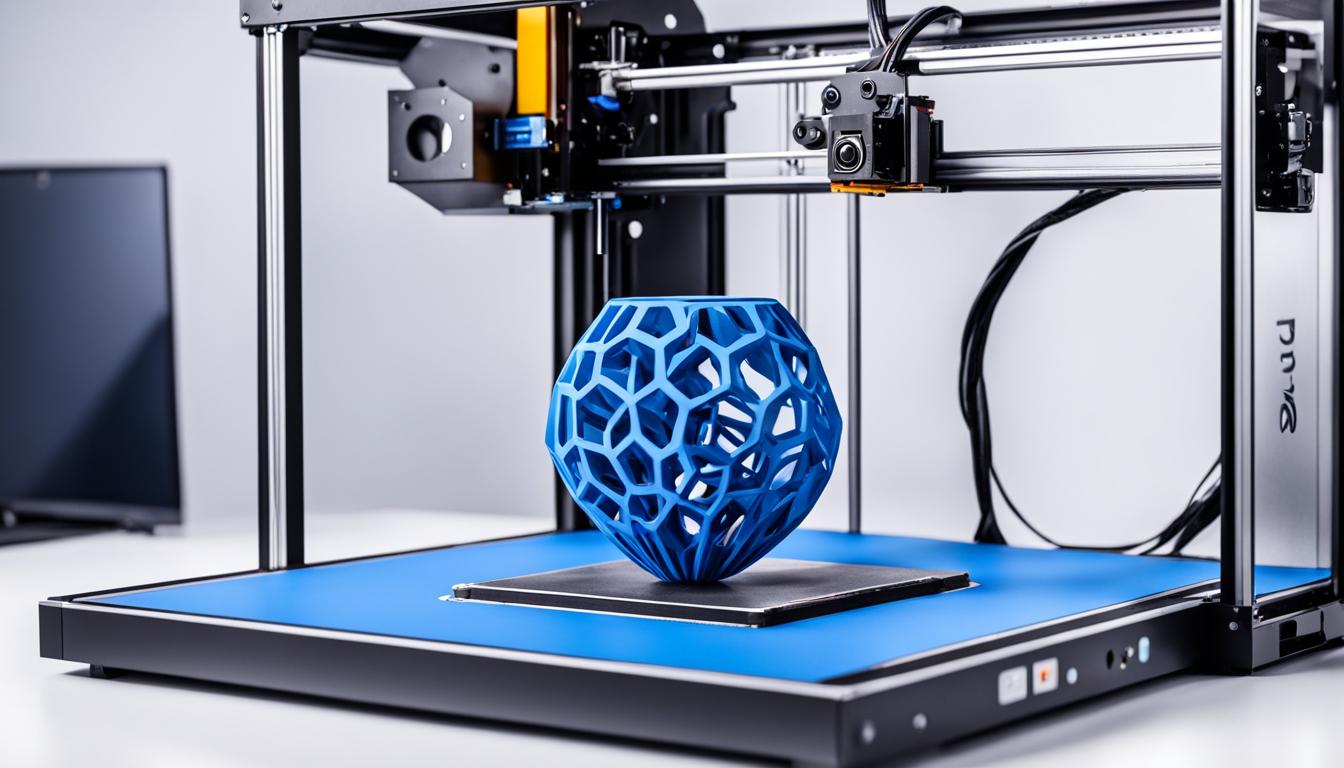

Zortrax 3D printers are renowned for their unmatched precision and quality in the 3D printing industry. As one of the best 3D printers available, Zortrax offers a range of high-quality, professional-grade printers that deliver exceptional results. Whether you need top-rated 3D printers for prototyping, production, or customization, Zortrax has the perfect solution for you.

With options like the Zortrax M200, Zortrax M300, Zortrax M200 Plus, Zortrax M300 Dual, and Zortrax M300 Plus, you can find an advanced and reliable printer that meets your specific requirements. Zortrax printers are known for being affordable while still providing cutting-edge technology and precision printing capabilities.

Positive reviews from users have established Zortrax as a trusted brand in the industry. Their printers consistently produce high-quality, accurate prints, making them a top choice for professionals in various fields.

Key Takeaways

- Zortrax 3D printers offer unmatched precision and quality.

- They are considered among the best, top-rated 3D printers.

- Zortrax printers deliver professional-grade, high-quality results.

- They are advanced, reliable, and affordable 3D printing solutions.

- Zortrax printers have positive reviews and are trusted in the industry.

Zortrax 3D Printers in the Automotive Industry

Zortrax 3D printers play a crucial role in the automotive industry, offering a wide range of applications and benefits. One of the primary uses of these printers is rapid prototyping, enabling manufacturers to quickly create prototypes of automotive parts and components. This allows for efficient testing and validation of designs before moving on to production.

Furthermore, Zortrax printers are utilized in short-series production, where clusters of printers can be employed to manufacture small batches of parts. This cost-effective approach enables the automotive industry to produce custom components and meet specific manufacturing needs without investing in expensive tooling.

Another significant application of 3D printing in the automotive industry is mass manufacturing, particularly for the production of jigs and fixtures used in traditional manufacturing processes. Zortrax 3D printers are employed to create these essential tools, enhancing the efficiency and accuracy of the overall manufacturing process.

3D printing also proves valuable in car restoration, where Zortrax printers are utilized to create replacement parts that closely match the look and feel of vintage vehicles. This allows car enthusiasts and restoration specialists to recreate historically accurate and functional components, even if original parts are no longer available.

Moreover, Zortrax 3D printers enable customization and tuning in the automotive industry. These printers empower car enthusiasts and manufacturers to design and manufacture unique and personalized components for customized vehicles. This level of customization enhances the overall aesthetics and performance of the vehicle, providing an invaluable opportunity for individual expression and differentiation.

A key advantage of Zortrax 3D printers in the automotive sector is their compatibility with a wide range of high-quality printing materials. These include reinforced, standard/engineering, metal, ceramic, high-temperature, and flame retardant materials. The versatility of these materials allows for the creation of durable end-use parts that meet the stringent standards of the automotive industry.

The Advantages of Zortrax 3D Printers in the Automotive Industry:

- Rapid prototyping for quick and efficient design validation

- Short-series production for cost-effective manufacturing

- Mass manufacturing of jigs and fixtures for enhanced efficiency

- Car restoration with accurate and functional vintage parts

- Customization and tuning for unique and personalized components

- Compatibility with a wide range of high-quality printing materials

Zortrax 3D printers have revolutionized the automotive industry, providing innovative solutions for rapid prototyping, short-series production, mass manufacturing, car restoration, customization, and tuning. With their compatibility with various high-quality printing materials, these printers enable manufacturers and enthusiasts to achieve exceptional precision and efficiency in creating automotive components.

Building a 3D Printing System in the Automotive Industry

Building an efficient and effective 3D printing system in the automotive industry requires careful consideration of the specific needs and requirements of the production environment. Whether it’s a large factory or a small workshop, choosing the right combination of 3D printers and post-processing devices is crucial to maximize productivity and meet the demands of the industry.

In a large factory setting, where high volume production is the priority, an optimal 3D printing system may consist of multiple Zortrax printers. The Zortrax M300 Plus, with its large build volume and exceptional precision, can handle the production of large parts and components. The Zortrax M300 Dual, with its dual extrusion system, allows for the simultaneous printing of multiple parts, increasing overall efficiency. Additionally, the Zortrax Inkspire 2, equipped with UV LCD technology, is ideal for manufacturing highly detailed and intricate parts.

Complementing these printers with post-processing devices such as the Zortrax Apoller for automated smoothing and vapor smoothing, the Zortrax Cleaning Station for thorough cleaning, and the Zortrax Curing Station for precise UV curing, results in a comprehensive 3D printing system that improves workflow and enhances the quality of the final prints.

In a small workshop, where budget and versatility are key factors, a more cost-effective 3D printing system can be built using a single Zortrax printer. The Zortrax M300 Plus or the Zortrax M300 Dual can address most of the needs of small workshops specializing in custom jobs, car tuning, or detailing. These printers offer reliable performance, high-quality prints, and ease of use, making them perfect for small-scale production and unique customization projects.

Alternatively, small workshops can also leverage the services of chosen 3D printing providers for more advanced materials or large-scale projects that may require specialized equipment that exceeds the capabilities of in-house printers.

Overall, building a 3D printing system in the automotive industry requires a careful assessment of the production environment and the specific needs of the business. Whether it’s a large factory or a small workshop, Zortrax offers a range of printers and post-processing devices to meet the demands of the automotive industry and facilitate the adoption of additive manufacturing technologies.

Examples of 3D Printing in the Automotive Industry

3D printing technology has made significant advancements in the automotive industry, driving innovation and transforming manufacturing processes. Several notable examples highlight its effectiveness in various applications.

Toyota

Toyota, a leading automobile manufacturer, utilizes Zortrax 3D printers in its manufacturing plants in Poland. These printers play a crucial role in assembling hybrid and conventional drives, facilitating the prototyping and production of various parts. The use of 3D printing technology enhances efficiency and enables faster iterations during the development stage.

RM Motors

RM Motors, a manufacturer specializing in car exhaust systems, leverages the power of Zortrax Endureal industrial 3D printers in its day-to-day operations. These advanced printers allow the company to upgrade its machines, resulting in improved efficiency and productivity. The ability to 3D print complex and customized exhaust components enhances the performance and uniqueness of their products.

Falectra

Falectra, a manufacturer of vintage scooters, integrates Zortrax desktop 3D printers into its manufacturing process. These printers enable Falectra to economically reproduce vintage scooter models, eliminating the need for expensive and hard-to-find spare parts. With 3D printing technology, Falectra can replicate intricate details and maintain the authenticity of classic scooter designs.

Alfa Project

Alfa Project, a company specializing in addressing parts availability challenges in the automotive sector, relies on Zortrax 3D printers. They utilize the printers to model and reproduce broken or unavailable car parts, ensuring the continuous operation of vintage and rare vehicles. By embracing 3D printing, Alfa Project provides innovative solutions to enhance the durability and performance of classic cars.

These examples demonstrate the transformative impact of 3D printing in the automotive industry. From prototyping to production and parts replication, 3D printing technology offers new possibilities and brings flexibility to the manufacturing and customization processes.

| Company | Application | Benefits |

|---|---|---|

| Toyota | Hybrid and conventional drive assembly | Efficient prototyping and production of parts |

| RM Motors | Car exhaust systems | Improved efficiency and machine upgrades |

| Falectra | Manufacturing vintage scooters | Economical reproduction of vintage scooter models |

| Alfa Project | Addressing parts availability challenges | Modeling and reproduction of broken or unavailable car parts |

Zortrax Inkspire: UV LCD 3D Printing Technology

The Zortrax Inkspire is a 3D printer that utilizes UV LCD technology to create high-quality and precise prints. This technology relies on a liquid photopolymer and UV light to build parts layer by layer, resulting in exceptional detail and accuracy.

Here is a breakdown of the printing process with the Zortrax Inkspire:

- Model Preparation: The printing process starts by preparing a model file in a 3D modeling software. Using Z-SUITE, the software designed for Zortrax printers, the model is sliced into layers to facilitate the printing process.

- Image Projection: The printer projects an image of each layer onto the transparent underside of the tank using UV light. This image masks the UV light passing through an LCD screen, ensuring that only the desired areas are cured.

- Layer Curing: The UV light emitted by the printer cures the liquid photopolymer, solidifying each layer. After the curing process, the platform rises and lowers itself to distribute the resin for the next layer.

Once the printing is complete, the model undergoes post-processing to achieve the desired properties:

- Cleaning: The printed model needs to be cleaned to remove any uncured resin. This can be done using an ultrasonic cleaner or a cleaning box, ensuring a smooth and flawless finish.

- UV Curing: After cleaning, the model is subjected to additional UV curing to enhance its strength and durability. This step ensures that the printed parts possess the necessary properties for their intended application.

The Zortrax Inkspire’s UV LCD technology offers a highly efficient and reliable printing process, resulting in exceptional print quality and intricate details in the final product.

| Advantages of Zortrax Inkspire UV LCD Technology | Benefits for Users |

|---|---|

| 1. High level of precision and accuracy | 1. Ability to create complex designs and detailed models |

| 2. Fast printing speed | 2. Reduced production time and faster turnaround |

| 3. Consistent and reliable print quality | 3. Guaranteed consistency and reliability in every print |

| 4. Compatibility with a wide range of materials | 4. Versatility in material selection for diverse applications |

| 5. Efficient use of resin | 5. Cost-effectiveness and reduced material wastage |

| 6. User-friendly interface and software | 6. Ease of use and streamlined workflow |

Zortrax Inkspire: Printing Process and Post-Processing

The printing process with the Zortrax Inkspire begins by preparing the model file in a 3D modeling software and slicing it into layers using Z-SUITE. The sliced file is then transferred to the printer, and the printing process can be started. The printer uses liquid resin, which needs to be carefully filled in the resin tank before printing.

During the printing process, the printer uses UV light to cure each layer of the model, and the platform rises and lowers itself to distribute the resin for the next layer. This precise curing process ensures the accurate formation of each layer, resulting in highly detailed and precise prints.

Once the printing is complete, the model needs to undergo post-processing to achieve its final form and properties. The first step in post-processing is cleaning the print to remove any uncured resin. This can be done using an ultrasonic cleaner or a cleaning box, ensuring that all excess resin is removed and the surface of the print is smooth and clean.

After cleaning, the model should be cured under UV light to fully solidify the resin and achieve its intended properties. This UV curing process provides additional strength and durability to the print, making it suitable for functional applications.

It is important to handle resins with care during the printing and post-processing process. Wearing safety gloves and glasses is recommended to protect the skin and eyes from any potential contact with the resin. Resin spills should be avoided, and the printer and surrounding workspace should be kept clean to ensure the best printing results.

A regular cleaning routine is essential to maintain the optimal performance of the Zortrax Inkspire. The resin tank should be cleaned regularly to remove any leftover resin or debris that may affect the quality of future prints. In addition, the FEP film in the tank may need to be replaced when necessary to ensure proper resin distribution during the printing process.

By following the printing process and post-processing guidelines for the Zortrax Inkspire, users can achieve high-quality prints with excellent accuracy and detail, making it a reliable choice for various 3D printing applications.

Zortrax Inkspire Printing Process and Post-Processing Summary

| Step | Description |

|---|---|

| 1 | Prepare the model file using 3D modeling software and slice it into layers using Z-SUITE. |

| 2 | Fill the resin tank with liquid resin. |

| 3 | Start the printing process, with the printer using UV light to cure each layer. |

| 4 | Post-process the print by cleaning it to remove uncured resin. |

| 5 | Cure the print under UV light to achieve its intended properties. |

| 6 | Handle resins with care, wearing safety gloves and glasses. |

| 7 | Maintain a clean workspace and regularly clean the resin tank. |

Zortrax Inkspire: Technical Terms

The Zortrax Inkspire is a 3D printer that operates using UV LCD technology. To fully understand the operation and functionality of this innovative printer, it is important to familiarize yourself with the technical terms associated with it.

Firmware

The firmware of the Zortrax Inkspire is responsible for controlling and monitoring all the data and functions of the printer. It ensures smooth operation and accurate execution of printing tasks.

FEP Film

The FEP film, a double-layered transparent foil, is installed in the resin tank of the Zortrax Inkspire. This film allows UV light to pass through and cure the liquid resin during the printing process. It ensures effective adhesion and consistent curing of each layer.

LCD Screen

The LCD screen plays a crucial role in the Zortrax Inkspire. It projects images of each layer onto the transparent underside of the resin tank, while masking the UV light. This process ensures precise and accurate printing by allowing only the desired areas to be cured.

Platform

The platform of the Zortrax Inkspire is an integral part of the printer where the models adhere during the printing process. It provides stability and support for the printed objects, ensuring optimal printing results.

Raft

In the context of the Zortrax Inkspire, the raft refers to the first few layers of resin that increase adhesion to the platform and support structures. It helps to maintain stability during the printing process and minimize the risk of warping or detachment.

Resin Tank

The resin tank is the container that holds the liquid resin throughout the printing process. It ensures a controlled environment for the resin, allowing for precise curing and building of each layer. The resin tank of the Zortrax Inkspire is designed to be durable and resistant to the effects of UV light.

By understanding these technical terms, users can gain a deeper insight into the inner workings of the Zortrax Inkspire and maximize their 3D printing experience.

Zortrax 3D Printers in the Automotive Industry: Advantages and Benefits

Zortrax 3D printers offer numerous advantages and significant benefits for the automotive industry. These printers are known for their precision and quality, making them ideal for prototyping and manufacturing in the automotive sector. The high level of accuracy and detail they provide ensures that automotive parts and components are produced to exact specifications, minimizing errors and reducing the need for expensive rework.

One of the key advantages of Zortrax 3D printers is their efficiency. These printers are designed to deliver quick turnaround times, allowing automotive companies to speed up the development and production processes. By utilizing 3D printing technology, companies can significantly reduce the time it takes to create prototypes and produce parts, resulting in improved efficiency and productivity.

Cost-effectiveness is another major benefit of Zortrax 3D printers in the automotive industry. Traditional manufacturing methods often require expensive tooling and molds, which can be a significant investment. However, with 3D printing, companies can minimize these costs as the need for tooling is greatly reduced. This not only saves money but also allows for more flexibility in design iterations and customization.

The ability to create custom components and parts on-demand is a significant advantage of Zortrax 3D printers. Automotive companies can easily adapt their designs and quickly produce parts to meet specific requirements. This eliminates the need for maintaining large inventories, reducing storage costs and the risk of obsolete inventory. Furthermore, customization options allow for the creation of unique and personalized components, catering to individual customer preferences and enhancing brand loyalty.

Zortrax 3D printers are known for their reliability and consistent results. The printers are built using high-quality components, ensuring durability and consistent performance over time. This reliability translates into the production of high-quality components that meet rigorous industry standards, ensuring customer satisfaction and the delivery of reliable automotive products.

Overall, the advantages and benefits of Zortrax 3D printers in the automotive industry include:

- Unmatched precision and quality

- Efficiency and quick turnaround times

- Cost-effectiveness compared to traditional manufacturing methods

- Flexibility in design and customization

- Reliability and consistent results

With these advantages, Zortrax 3D printers prove to be invaluable tools in the automotive industry, revolutionizing the way automotive companies prototype, manufacture, and customize components and parts.

Advantages and Benefits of Zortrax 3D Printers in the Automotive Industry

| Advantages | Benefits |

|---|---|

| Precision and quality | – Accurate and detailed prints – Minimizes errors and rework |

| Efficiency | – Quick turnaround times – Speeds up development and production processes |

| Cost-effectiveness | – Reduces tooling and mold costs – Minimizes storage costs and inventory obsolescence |

| Flexibility | – On-demand production of custom components – Design iterations and customization options |

| Reliability and Consistency | – Durable and high-quality components – Meets rigorous industry standards |

Conclusion

Zortrax 3D printers have become leaders in the 3D printing industry, particularly in the automotive sector. With their exceptional precision and ability to deliver high-quality prints, Zortrax printers offer reliable and efficient solutions for prototyping, production, and customization. Utilizing advanced materials and cutting-edge technology, these printers ensure the production of durable and precise automotive components.

Whether in large factories or small workshops, Zortrax 3D printers have proven to be an optimal choice, providing tailored 3D printing systems for different production environments. The positive feedback and wide adoption of Zortrax printers in the automotive industry attest to their quality and performance.

For professionals seeking high-quality 3D printing solutions that meet the demanding requirements of the automotive industry, Zortrax 3D printers remain a top choice. Their ability to deliver unmatched precision and produce exceptional results make them invaluable tools for those in need of high-quality 3D printing for automotive applications.