CNC machines represent a revolutionary advancement in manufacturing technology, offering unparalleled precision and efficiency in producing complex parts and components. These automated systems excel in executing intricate designs with remarkable accuracy, consistently replicating results across large production runs. The versatility of CNC machines allows for the creation of a wide range of products, from aerospace components to medical devices, with minimal human intervention. However, this cutting-edge technology comes with significant drawbacks.

The initial investment for CNC equipment is substantial, often requiring considerable capital outlay. Additionally, the complexity of these machines demands highly skilled operators and programmers, increasing labor costs and training requirements. Maintenance and repair expenses can also be substantial, potentially leading to costly downtime. While CNC machines reduce human error in production, they are susceptible to software glitches and mechanical failures that can result in expensive mistakes or production halts.

The high degree of automation may lead to job displacement in traditional manufacturing roles, raising concerns about workforce adaptation. Despite these challenges, the benefits of CNC technology—including improved product quality, increased production speed, and the ability to create complex geometries—continue to drive its adoption across various industries, balancing the marvels of precision engineering with the pitfalls of technological dependence and economic considerations.

Advantages of CNC Machines

Unparalleled Precision

One of the most remarkable advantages of CNC machines is their ability to deliver unparalleled precision in the manufacturing process. The computer-controlled nature of these machines ensures consistently accurate results, eliminating the human errors often associated with manual machining. This level of precision enables the creation of intricate and complex components, revolutionizing industries that require exacting specifications.

Enhanced Efficiency and Productivity

CNC machines drastically improve manufacturing efficiency and productivity. They can operate continuously, 24/7, with minimal human intervention, which reduces downtime and maximizes output. Moreover, once a design program is perfected, it can be easily replicated, saving significant time and resources in subsequent productions.

Versatility and Adaptability

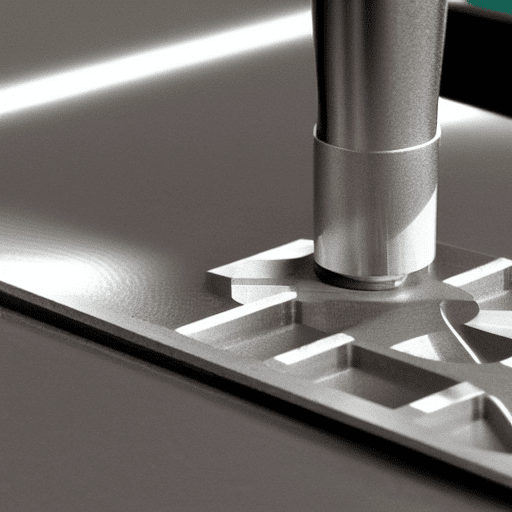

CNC machines are incredibly versatile, capable of working with various materials, including metals, plastics, composites, and wood. They can handle diverse tasks such as cutting, drilling, milling, turning, and 3D printing, making them ideal for multifaceted manufacturing processes. With updated software and tooling, these machines can be adapted to meet changing production demands.

Complex Geometries and Customization

The level of intricacy and complexity that CNC machines can achieve is unparalleled. They can fabricate intricate designs and complex geometries that were once deemed impractical or impossible. This capability empowers industries to create unique, customized products, enabling personalization and innovation.

Safer Working Environment

Automation provided by CNC machines results in a safer working environment for operators. Dangerous and labor-intensive tasks are now performed by the machine, reducing the risk of workplace accidents and injuries. Additionally, the enclosed nature of CNC machines protects workers from dust, debris, and hazardous materials.

Disadvantages of CNC Machines

High Initial Investment

Acquiring and setting up CNC machines requires a substantial initial investment. The cost includes the machine itself, computer software, maintenance, and skilled operators who can program and operate the machines effectively. For small businesses or startups, this cost may pose a significant barrier to entry.

Complexity and Skill Requirements

While CNC machines simplify the manufacturing process, they demand skilled operators to program and supervise their operations. Understanding computer programming and the intricacies of CNC machining can be a steep learning curve for operators. This results in a shortage of qualified personnel, driving up labor costs and intensifying competition for skilled workers.

Vulnerability to Software and Technical Issues

CNC machines heavily rely on computer software, making them susceptible to software glitches, bugs, and cyber threats. A software malfunction or technical issue can halt production and lead to costly downtime. Regular maintenance and updates are crucial to mitigate these risks, but they add to the overall operational expenses.

Lack of Flexibility in Small Production Runs

While CNC machines excel at large-scale production, they may not be the most cost-effective option for small production runs or prototyping. The time and resources required for programming and setup can outweigh the benefits of automation when producing only a limited number of items.

Unemployment Concerns

The automation capabilities of CNC machines have raised concerns about job losses in the manufacturing industry. As machines replace certain manual tasks, some workers may face displacement or need to acquire new skills to adapt to the changing job landscape.

Frequently Asked Questions

What is a CNC machine, and how does it work? A CNC (Computer Numerical Control) machine is a manufacturing tool that utilizes computerized controls to automate the movement of machine tools. It follows pre-programmed instructions to cut, mill, grind, or shape various materials with exceptional precision. CNC machines read and execute G-code, a language that specifies the machine’s movements and actions.

What are the marvels of using CNC machines? CNC machines offer numerous advantages, including:

- Unparalleled Precision: CNC machines can produce highly accurate and consistent parts, ensuring tight tolerances and better quality products.

- Increased Efficiency: Automation reduces human errors and speeds up production, resulting in higher throughput and reduced lead times.

- Versatility: These machines can work with a wide range of materials, from metals to plastics and wood, making them suitable for various industries.

- Complex Designs: CNC machines excel at creating intricate and complex designs that would be challenging or impossible to achieve manually.

What are the primary pitfalls associated with CNC machines? While CNC machines offer remarkable benefits, they also come with some challenges, such as:

- High Initial Investment: Acquiring and setting up CNC machines can be expensive, especially for smaller businesses or startups.

- Skilled Operator Requirement: Operating a CNC machine requires specialized knowledge and training. Skilled operators are crucial for efficient and safe production.

- Maintenance Costs: CNC machines need regular maintenance to ensure they continue operating optimally. Maintenance costs can add up over time.

- Limited Flexibility: While CNC machines are great for repetitive tasks and mass production, they might not be as suitable for one-off or highly customized projects.

What industries benefit the most from CNC machines? CNC machines find applications in a wide array of industries, including:

- Manufacturing: CNC machines are extensively used in industries producing automotive components, aerospace parts, electronics, and machinery.

- Woodworking: CNC routers enable precise and intricate woodwork for furniture, cabinetry, and artistic creations.

- Medical: CNC machines are involved in manufacturing medical implants, prosthetics, and surgical instruments.

- Prototyping: Product development and rapid prototyping benefit from the accuracy and speed of CNC machines.

How can I ensure the best results with CNC machining? To achieve optimal results with CNC machines:

- Work with Skilled Operators: Employ or train operators who possess a strong understanding of CNC programming and machining techniques.

- Use Quality Materials: Utilize high-quality materials to ensure the final product’s durability and performance.

- Regular Maintenance: Implement a strict maintenance schedule to keep the machines running smoothly and prevent costly breakdowns.

- Optimize Designs: Collaborate with designers who are familiar with CNC capabilities to create efficient and feasible designs.

Are there different types of CNC machines available? Yes, CNC machines come in various types, each specializing in specific tasks. Some common types include CNC mills, lathes, routers, plasma cutters, and 3D printers. Each machine has its unique set of capabilities and applications.

Can CNC machines replace traditional manual machining methods entirely? While CNC machines are incredibly powerful, they might not replace traditional manual machining entirely. Some tasks may still require the human touch, particularly for highly customized or artistic work. Manual machining can also be more cost-effective for smaller production runs.

How do I choose the right CNC machine for my needs? Selecting the right CNC machine involves considering factors such as your budget, production requirements, materials you’ll be working with, and the complexity of your projects. Consulting with CNC machine manufacturers or industry experts can help you make an informed decision.

What safety precautions should be taken when using CNC machines? Safety is paramount when operating CNC machines. Some essential precautions include:

- Proper Training: Ensure that all operators receive comprehensive training in machine operation and safety protocols.

- Safety Gear: Operators should wear appropriate personal protective equipment (PPE), such as safety glasses and gloves.

- Machine Enclosures: Install machine enclosures and safety barriers to prevent accidents and protect workers from moving parts.

- Emergency Stop: Have accessible emergency stop buttons to halt operations quickly in case of emergencies.

How can I justify the cost of investing in CNC machines for my business? To justify the cost of CNC machines, consider factors like increased production efficiency, reduced waste, improved product quality, and the ability to take on more complex projects. Calculate potential cost savings over time and weigh them against the initial investment to make an informed decision.

Conclusion

CNC machines are undeniably a marvel of modern engineering, offering precise, efficient, and versatile manufacturing capabilities. They have revolutionized industries, pushing the boundaries of what was once thought possible. However, these powerful machines also come with their fair share of drawbacks, from the substantial initial investment to the need for skilled operators and vulnerability to technical issues.

As with any technological advancement, it is essential to strike a balance and make informed decisions about their integration into various industries. Acknowledging both the advantages and disadvantages of CNC machines empowers businesses to leverage their strengths while mitigating potential pitfalls. Ultimately, a thoughtful and strategic approach to implementing CNC technology can unlock its full potential and drive progress in the world of manufacturing.