CNC (Computer Numerical Control) engineering is a form of engineering that uses computer-controlled machines to automate the production of parts and components. CNC engineering is used in a variety of industries, including aerospace, automotive, medical, and consumer products. CNC engineering is a highly specialized field that requires a combination of technical knowledge and engineering skills.

CNC engineering involves the use of computer-controlled machines to produce parts and components with precision and accuracy. The machines are programmed with instructions that tell them how to move and shape the material. The instructions are written in a computer language called G-code, which is a set of commands that tell the machine what to do. The G-code is written in a text editor, and then the instructions are sent to the machine.

CNC engineering requires a thorough understanding of the machines and the materials being used. The engineer must be able to read and interpret the G-code, as well as understand the properties of the materials being used. The engineer must also be able to troubleshoot any problems that may arise during the production process.

CNC engineering is a highly technical field that requires a great deal of skill and knowledge. It is important for engineers to stay up to date on the latest technology and techniques in order to remain competitive in the industry. CNC engineering is a rewarding and challenging career that can lead to a successful and fulfilling career.

What does CNC in engineering mean?

CNC stands for Computer Numerical Control, and it is a type of automation used in engineering and manufacturing. It is a process in which a computer is used to control the movement of tools and machinery in order to create a desired product. CNC machines are programmed with a set of instructions that tell the machine what to do and how to do it. The instructions are written in a computer language called G-code, which is a language specifically designed for CNC machines. The instructions are then sent to the machine, which then follows the instructions to create the desired product.

CNC machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products. They are used to create a wide range of products, from simple parts to complex components. CNC machines are highly accurate and can produce products with a high degree of precision. They are also very efficient, as they can produce products quickly and with minimal waste.

Is CNC is a good career?

CNC (Computer Numerical Control) is a great career choice for those who are interested in working with machines and technology. CNC is a type of machining process that uses computer-controlled machines to cut and shape materials into desired shapes and sizes. CNC machinists use computer-aided design (CAD) software to create 3D models of the parts they are creating, and then use CNC machines to cut and shape the materials into the desired shape. CNC machinists must be highly skilled in both the software and the machines they use, as well as have a good understanding of the materials they are working with.

CNC machinists are in high demand in many industries, including automotive, aerospace, medical, and manufacturing. The job outlook for CNC machinists is expected to remain strong, as the demand for skilled machinists is expected to continue to grow. CNC machinists can expect to earn a competitive salary, and many employers offer benefits such as health insurance and retirement plans.

What job is a CNC?

A CNC (Computer Numerical Control) operator is a skilled technician who operates a CNC machine to produce precision parts and components. CNC machines are computer-controlled tools that use programmed instructions to cut and shape materials such as metal, plastic, and wood. CNC operators are responsible for setting up and operating the machines, as well as monitoring the progress of the parts being produced. They must also be able to troubleshoot any problems that arise during the production process. CNC operators must have a good understanding of the machines they are working with, as well as the materials they are cutting and shaping.

They must also be able to read and interpret blueprints and other technical drawings. CNC operators must also be able to use a variety of measuring tools and instruments to ensure that the parts they are producing meet the required specifications. CNC operators must also be able to make adjustments to the machines as needed to ensure that the parts being produced are of the highest quality.

How is CNC used today?

Computer Numerical Control (CNC) is a technology that has been used in manufacturing for decades. It is a process that uses computer-controlled machines to automate the production of parts and components. CNC machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products.

CNC machines are programmed with a set of instructions that tell the machine how to move and what operations to perform. The instructions are written in a computer language called G-code. The G-code is then loaded into the CNC machine, which then follows the instructions to produce the desired part or component.

CNC machines are used to produce parts and components with high precision and accuracy. They can be used to produce parts with complex shapes and intricate details that would be difficult or impossible to produce with traditional machining methods. CNC machines are also capable of producing parts with tight tolerances and repeatable results.

What is CNC programming?

CNC programming is a process used in manufacturing that involves the use of computer numerical control (CNC) machines to create parts and products. CNC programming is used to control the movements of the machine, as well as the speed and feed rate of the cutting tool. CNC programming is used to create a program that will tell the machine what to do and how to do it. The program is written in a language called G-code, which is a set of instructions that the machine can understand. The G-code is then loaded into the machine and the machine will execute the instructions.

CNC programming is used in a variety of industries, including aerospace, automotive, medical, and consumer products. It is used to create parts and products with a high degree of accuracy and repeatability. CNC programming is also used to create complex shapes and patterns that would be difficult or impossible to create with traditional machining methods.

CNC programming is a complex process that requires a good understanding of the machine, the material being machined, and the G-code language.

Is CNC part of engineering?

Yes, CNC (Computer Numerical Control) is a part of engineering. CNC is a type of automation technology that uses computer-controlled machines to perform a variety of tasks. It is used in a wide range of industries, including manufacturing, automotive, aerospace, and medical. CNC machines are programmed to perform specific tasks, such as cutting, drilling, and milling. They are used to create parts and components for a variety of products, from cars to medical devices.

CNC technology is used in many engineering fields, including mechanical engineering, electrical engineering, and computer engineering. It is used to create parts and components for a variety of products, from cars to medical devices. CNC machines are programmed to perform specific tasks, such as cutting, drilling, and milling. They are used to create parts and components for a variety of products, from cars to medical devices.

What is CNC and how it works?

Computer Numerical Control (CNC) is a manufacturing process that uses computer-controlled machines to automate the production of parts and components. CNC machines are programmed with a set of instructions that tell the machine how to move and what to do. The instructions are written in a computer language called G-code, which is a language specifically designed for CNC machines.

The CNC process begins with a CAD (Computer Aided Design) drawing of the part or component that needs to be produced. This drawing is then converted into a set of instructions that the CNC machine can understand. The instructions are written in G-code and are then loaded into the CNC machine.

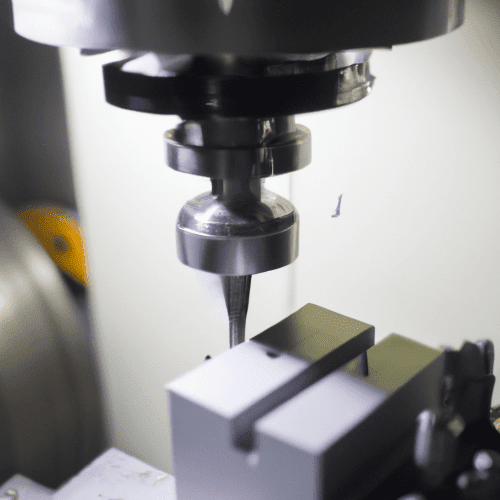

Once the instructions are loaded, the CNC machine is ready to begin production. The CNC machine is equipped with a variety of tools, such as drills, saws, and lathes, that are used to cut and shape the material into the desired shape. The CNC machine is also equipped with a computer-controlled motor that moves the tools in the desired direction.

What is a CNC course?

A CNC (Computer Numerical Control) course is a type of training program that teaches students how to use computer-controlled machines to create parts and components for a variety of industries. CNC courses typically cover topics such as machine setup, programming, and operation, as well as safety and maintenance. Students learn how to use CNC machines to create parts and components with precision and accuracy. They also learn how to troubleshoot and repair CNC machines, as well as how to read and interpret blueprints and drawings. CNC courses are often offered at technical schools, community colleges, and universities, and can be taken as part of a certificate or degree program. CNC courses are also available online, allowing students to learn at their own pace and in their own time.