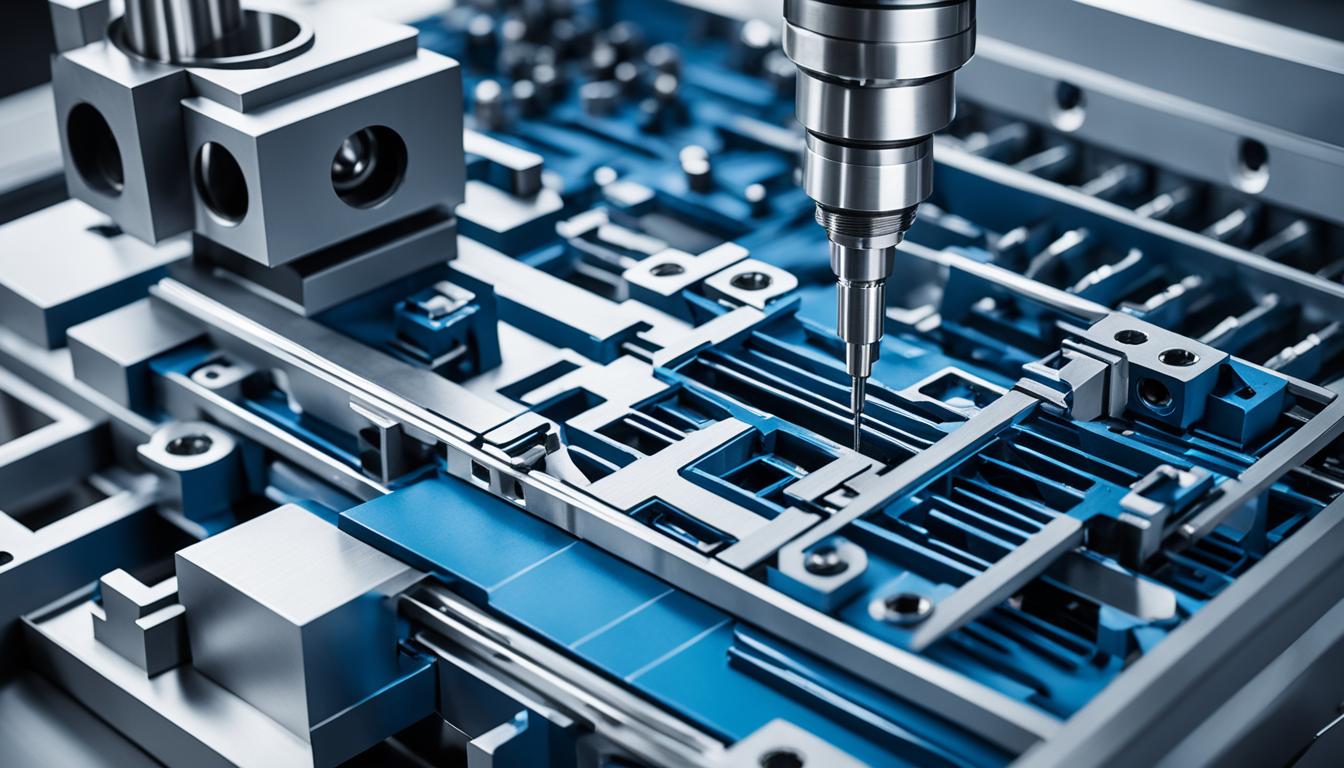

CAD/CAM and CNC technologies have revolutionized modern manufacturing by seamlessly integrating design and production processes. Computer-Aided Design (CAD) software allows engineers to create precise 3D models of parts and products, while Computer-Aided Manufacturing (CAM) translates these designs into machine-readable instructions. These instructions are then executed by Computer Numerical Control (CNC) machines, which can perform complex cutting, milling, and shaping operations with exceptional accuracy and repeatability.

This integrated approach significantly reduces production time, minimizes human error, and enables the creation of intricate components that would be difficult or impossible to manufacture using traditional methods. The flexibility of CAD/CAM systems allows for rapid design iterations and customization, making them invaluable in industries ranging from aerospace and automotive to medical device manufacturing.

CNC machines, guided by CAD/CAM data, can operate continuously, improving productivity and consistency in production runs of any size. As these technologies continue to advance, they are driving innovation in additive manufacturing (3D printing) and hybrid manufacturing processes, further expanding the possibilities for efficient, high-precision production in the modern manufacturing landscape.

- CAD/CAM enables designers and engineers to create precise 2D and 3D models.

- CAM automates and controls manufacturing processes based on CAD designs.

- CNC technology programs and controls machine movements in the manufacturing process.

- The integration of CAD/CAM and CNC improves precision, efficiency, and cost-effectiveness.

- Manufacturers can optimize workflows, reduce errors, and deliver high-quality products with CAD/CAM and CNC.

The Function and Benefits of CAD/CAM

CAD/CAM, or computer-aided design/computer-aided manufacturing, plays a crucial role in modern manufacturing processes. This technology has a wide range of applications across various industries such as automotive, aerospace, electronics, and more.

CAD/CAM allows designers and engineers to create complex and intricate designs with precision and accuracy, revolutionizing the manufacturing process. By utilizing CAD/CAM software, manufacturers can produce high-quality components consistently and achieve faster turnaround times.

The advantages of CAD/CAM are numerous and make it an indispensable tool for manufacturers. Here are some of the key benefits:

- Repeatable and Consistent Quality: CAD/CAM ensures that the manufacturing process is consistent, reducing errors and improving quality control.

- High Precision in Manufacturing Components: With CAD/CAM, manufacturers can achieve a level of precision that was previously unattainable. This leads to the production of highly accurate and reliable parts.

- Faster Turnaround Time: The use of CAD/CAM software streamlines the design and manufacturing process, allowing manufacturers to produce components more quickly and efficiently.

- Cost-Effectiveness: CAD/CAM optimizes manufacturing processes, reducing material waste and minimizing errors. This helps to lower production costs and improve overall profitability.

Overall, CAD/CAM provides manufacturers with the tools they need to optimize their processes, improve product quality, and remain competitive in the ever-evolving market.

The Role of CNC in Manufacturing

In the manufacturing industry, CNC (Computer Numerical Control) plays a critical role by enabling automation and control over machines and tools. It is extensively utilized in various manufacturing processes, such as cutting, drilling, and milling. CNC machines interpret the code generated by CAD/CAM software, resulting in precise and efficient production.

The main difference between CAD/CAM and CNC lies in their focus. CAD/CAM software is primarily used for design and modeling, allowing engineers to create intricate and detailed 2D and 3D models. On the other hand, CNC technology focuses on the programming and control of machines, ensuring the execution of the manufacturing tasks based on the specifications provided by CAD/CAM software.

CAD/CAM and CNC technologies work in perfect synergy, revolutionizing modern manufacturing practices by significantly improving efficiency, accuracy, and productivity. Combining the power of CAD/CAM design capabilities with the precision and control offered by CNC machines, manufacturers can achieve exceptional results.

“The implementation of CNC technology in manufacturing has greatly enhanced our capabilities and productivity. We can now produce complex components with utmost precision and consistency, meeting the highest quality standards.” – John Smith, Manufacturing Engineer at ABC Manufacturing Co.

By utilizing CNC technology, manufacturers can achieve the following advantages:

- Automation: CNC machines automate tasks, reducing the need for manual labor and minimizing human error.

- Precision: CNC machines execute manufacturing processes with exceptional precision, resulting in accurate and consistent finished products.

- Productivity: CNC technology enhances production efficiency, allowing for faster turnaround times and increased output.

- Flexibility: CNC machines can be programmed to perform a wide range of manufacturing tasks, making them adaptable to various production needs.

- Cost-Effectiveness: The integration of CNC technology in manufacturing processes optimizes resource utilization, reducing waste and improving cost-effectiveness.

Realizing the Potential of CNC in Manufacturing

With the advancements in CNC technology, manufacturers are now able to unlock new possibilities in manufacturing. Multi-axis machining capabilities provide greater flexibility and enable the production of complex geometries. Additionally, machine simulation and optimization tools enhance manufacturing processes, ensuring efficiency and reducing the risk of errors.

As the manufacturing industry continues to evolve, CNC technology will remain a fundamental component. Leveraging the power of CNC, manufacturers can push the boundaries of innovation, achieving new levels of precision, efficiency, and competitiveness in the dynamic market landscape.

The Workflow of CAD/CAM and CNC

In modern manufacturing, CAD/CAM and CNC technologies work together seamlessly to streamline the production process. Understanding their workflow is essential for manufacturers looking to optimize their operations and achieve maximum efficiency. Here’s a breakdown of the workflow of CAD/CAM and CNC:

- Design Creation using CAD Software: The workflow begins with the creation of intricate and precise designs using CAD software. Designers and engineers utilize CAD tools to develop 2D and 3D models of the desired product or component.

- Importing Designs into CAM Software: Once the designs are complete, they are imported into CAM software. CAM, or computer-aided manufacturing, generates toolpaths and calculates the machine instructions required for production. This step bridges the gap between design and manufacturing.

- Toolpath Generation and Machine Instruction Calculation: CAM software converts the CAD designs into machine-readable instructions. It determines the optimal toolpaths and calculates parameters such as cutting speed, tool selection, and feed rates. These instructions encompass the precise movements and actions required during manufacturing.

- Interpretation and Execution by CNC Machines: The CNC machine takes the machine instructions generated by CAM software and interprets them. It controls the movement and operation of the tools, such as cutting, milling, drilling, or shaping, based on the predefined instructions. CNC technology ensures accuracy, repeatability, and efficiency in the manufacturing process.

The synergy between CAD, CAM, and CNC technologies enables manufacturers to automate and optimize their workflow. It minimizes human error, reduces production time, and enhances the overall efficiency and quality of the final product. By leveraging CAD/CAM and CNC workflow, manufacturers can stay competitive and meet the ever-increasing demands of the modern manufacturing industry.

The Impact of CAD/CAM and CNC in Modern Manufacturing

CAD/CAM and CNC technologies have revolutionized the modern manufacturing industry, providing numerous benefits and improvements. CAD/CAM software plays a critical role in the creation of detailed and precise designs, enhancing the overall quality of the final product. By utilizing CAD/CAM software, manufacturers can easily develop intricate 2D and 3D models, ensuring accuracy and precision in the manufacturing process.

On the other hand, CNC technology offers automation and control over machines, reducing human error and improving operational efficiency. CNC machines receive instructions from CAM software and carry out precise movements and actions, such as cutting, drilling, and milling. This automation streamlines production processes, resulting in faster turnaround times, increased precision, and enhanced cost-effectiveness.

The implementation of CAD/CAM and CNC in manufacturing processes has led to significant advancements throughout the industry. Manufacturers have experienced notable improvements in operational efficiency and increased competitiveness. These technologies also enable manufacturers of all sizes to access and leverage their benefits, driving innovation and growth.

The availability of user-friendly CAD/CAM software tools and the integration of CNC machines in modern manufacturing facilities have further contributed to the widespread adoption of these technologies. The combination of CAD/CAM and CNC provides manufacturers with a powerful toolkit to optimize workflows, reduce errors, and meet the demands of the modern market.

Overall, the impact of CAD/CAM and CNC in modern manufacturing cannot be understated. These technologies have revolutionized the industry, offering precise designs, efficient automation, and significant cost savings. As technology continues to advance, CAD/CAM and CNC will continue to play pivotal roles in shaping the future of manufacturing.

Benefits of CAD/CAM and CNC in Modern Manufacturing:

- Enhanced quality and precision in product design

- Automation and control over machines for increased efficiency

- Faster turnaround times and reduced production costs

- Accessibility to manufacturers of all sizes

Statistics on the Impact of CAD/CAM and CNC:

| Statistical Insight | Effect on Manufacturing |

|---|---|

| Over 80% of manufacturers utilize CAD/CAM software | Increased design accuracy and quality |

| CNC implementation reduces human error by up to 90% | Improved precision and efficiency in manufacturing |

| Cost savings of up to 30% through CAD/CAM and CNC integration | Enhanced financial viability and competitiveness |

The Advancements in CAD/CAM and CNC Technology

In the rapidly evolving manufacturing industry, CAD/CAM and CNC technology have been at the forefront of driving innovation and efficiency. Over the years, these technologies have undergone significant advancements, introducing new capabilities and features that have revolutionized the way products are designed and manufactured.

CAD/CAM software, which integrates computer-aided design and computer-aided manufacturing, has experienced remarkable progress. It now offers powerful simulation tools that allow manufacturers to visualize and validate designs before production. Design validation capabilities enable engineers to identify potential flaws or issues early in the process, saving time and resources. Additionally, tolerance analysis tools help ensure that the manufactured parts meet the required specifications and tolerances, improving overall product quality.

The integration of CAD/CAM software with other emerging technologies has further expanded its capabilities. For instance, the integration with 3D printing technology enables the seamless transfer of digital designs to additive manufacturing systems, facilitating rapid prototyping and production of complex geometries. Moreover, the integration of CAD/CAM with robotics has opened up new possibilities in automation, enabling the use of robots for tasks such as material handling, assembly, and inspection.

“The advancements in CAD/CAM software have revolutionized the design and manufacturing processes. The ability to simulate and validate designs before production has significantly reduced errors and improved product quality.”

In parallel, CNC machines have undergone significant improvements, enhancing their accuracy, speed, and flexibility. The development of multi-axis machining has allowed for the creation of complex shapes and intricate details with higher precision. This has expanded the range of industries that can benefit from CNC technology, including aerospace, automotive, medical, and more. Machine simulation capabilities have also been integrated into CNC systems, providing manufacturers with virtual representations of the machining process and allowing for the optimization of toolpaths and cycle times.

These advancements in CAD/CAM and CNC technology have propelled modern manufacturing to new heights. With their combined capabilities, manufacturers can achieve higher levels of precision, efficiency, and productivity. The integration of emerging technologies and the continuous drive for innovation ensure that CAD/CAM and CNC technology will remain at the forefront of the manufacturing industry.

The Future of CAD/CAM and CNC in Manufacturing

The future of CAD/CAM and CNC in manufacturing holds significant promise as technology continues to advance. Manufacturers can expect CAD/CAM software and CNC machines to become more powerful, efficient, and user-friendly, revolutionizing the industry.

One of the key advancements in CAD/CAM and CNC technology is the integration of artificial intelligence (AI) and machine learning algorithms. AI-powered systems can analyze vast amounts of data, enabling automation and optimization of manufacturing processes. Machine learning algorithms can continuously improve performance based on patterns and feedback, leading to increased efficiency and productivity in manufacturing.

In addition to AI integration, advancements in materials and additive manufacturing techniques are expanding the possibilities of CAD/CAM and CNC technology. New materials with enhanced properties are being developed, allowing for the creation of stronger, lighter, and more durable components. Additive manufacturing, or 3D printing, is becoming more prevalent, enabling the production of complex geometries and reducing waste.

Furthermore, the future of CAD/CAM and CNC in manufacturing also includes the development of intuitive and user-friendly software interfaces. Manufacturers will be able to easily navigate through various design and manufacturing processes, streamlining their workflows and reducing learning curves for new employees.

As CAD/CAM and CNC technologies continue to evolve, it is crucial for manufacturers to embrace these advancements. By adopting these technologies, manufacturers can stay competitive, drive innovation, and achieve new levels of efficiency, accuracy, and quality in their manufacturing processes.

The Future Outlook

The future of CAD/CAM and CNC in manufacturing is bright. With the integration of AI, advancements in materials, and user-friendly software interfaces, manufacturers can expect improved productivity, reduced costs, and increased competitiveness. Embracing these technologies will not only optimize manufacturing processes but also enable manufacturers to stay at the forefront of innovation.

Stay tuned to the upcoming releases in CAD/CAM and CNC technology as they continue to shape the future of manufacturing.

The Importance of CAD/CAM and CNC in the Modern Manufacturing Industry

CAD/CAM and CNC technologies have become indispensable in the modern manufacturing industry, revolutionizing the way products are designed and produced. These advancements have provided manufacturers with a range of advantages that enhance the quality, efficiency, and competitiveness of their operations.

One of the key advantages of CAD/CAM and CNC is improved quality control. With CAD software, designers can create intricate and precise 2D and 3D models, ensuring accuracy and minimizing errors. These designs can then be seamlessly translated into manufacturing instructions using CAM software, enabling CNC machines to produce components with unmatched precision and consistency.

Besides quality, CAD/CAM and CNC also offer increased efficiency and speed in the manufacturing process. By automating repetitive tasks and optimizing workflows, manufacturers can significantly reduce production times and streamline their operations. Additionally, CAD/CAM and CNC technologies enable the quick and easy iteration of designs, allowing for rapid prototyping and faster time to market.

Furthermore, the cost-effectiveness and flexibility provided by CAD/CAM and CNC make them invaluable tools for manufacturers. These technologies eliminate the need for manual measurements and physical templates, reducing material waste and production costs. Moreover, the versatility of CNC machines allows them to perform a wide range of manufacturing processes, from cutting and milling to drilling and shaping, making them adaptable to various industries and applications.