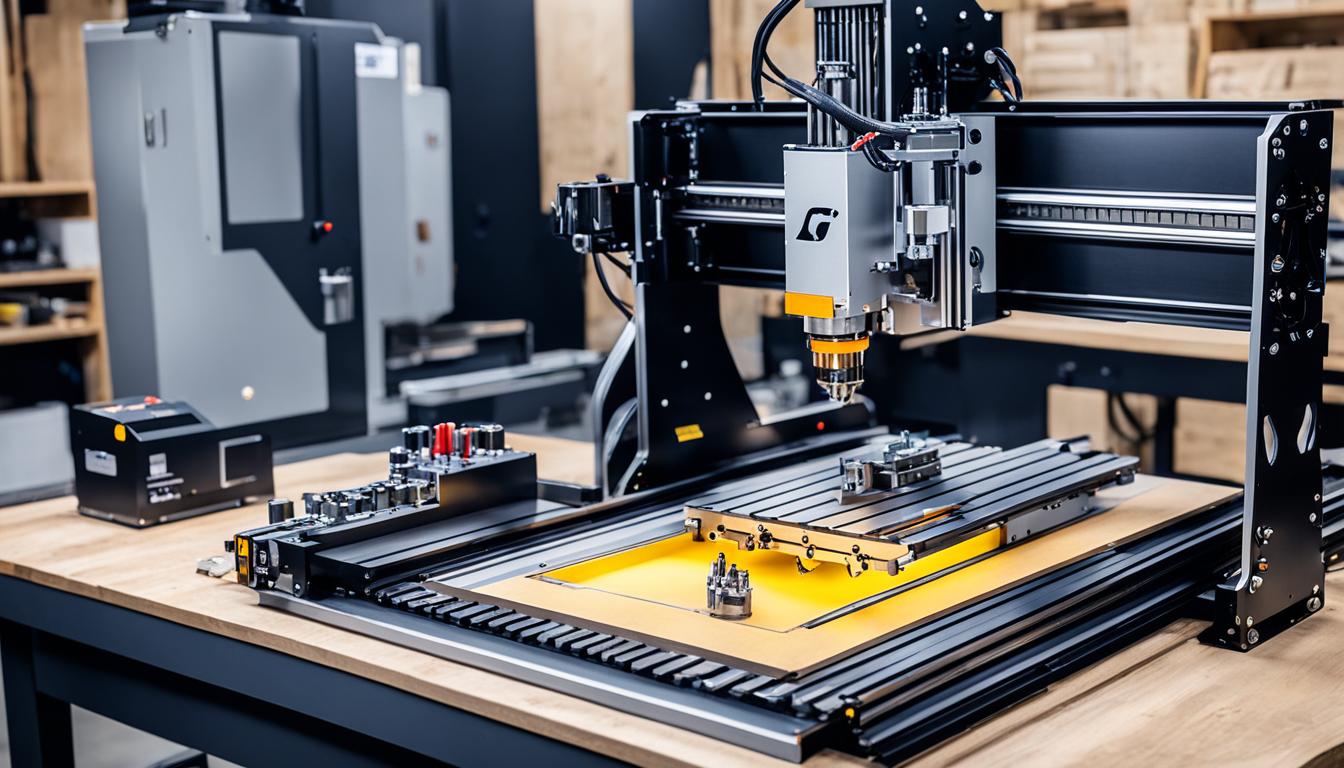

OpenBuilds CNC offers a comprehensive DIY solution for those looking to enter the world of computer numerical control machining. This modular system provides everything needed to build a functional CNC router, from hardware components to software tools. OpenBuilds machines are designed with versatility in mind, capable of cutting materials like wood, plastics, and aluminum.

The company offers various machine bundles to suit different project sizes, with options ranging from smaller desktop models to larger workbench-sized units. Assembly is made accessible through step-by-step build videos, allowing users to construct their CNC router alongside expert guidance. The system includes essential components such as the BlackBox Motion Control System, NEMA 23 motors, and a 24V power supply bundle.

OpenBuilds also provides free software solutions – OpenBuild CAM for design and toolpath generation, and OpenBuilds CONTROL for machine operation. This combination of hardware and software empowers users to create, customize, and execute CNC projects with relative ease, making OpenBuilds an attractive option for hobbyists, makers, and small businesses venturing into CNC technology.

- OpenBuilds CNC machines offer an all-in-one solution for DIY enthusiasts and makers.

- The OpenBuilds Black Box combines motion control and software in a compact package.

- Setting up and operating an OpenBuilds CNC machine is simple and convenient.

- The Black Box includes its own control software, eliminating the need for additional purchases.

- OpenBuilds CNC machines are suitable for both hobbyists and professionals.

Overview of the Open Builds Black Box

The Open Builds Black Box is an all-in-one motion controller board designed specifically for CNC machines. This compact and convenient solution offers precise control and operation of CNC machines, making it an ideal choice for DIY enthusiasts and professionals alike. With its built-in USB port, the Black Box allows for seamless connection and communication with your CNC machine. Additionally, it comes with its own control software, eliminating the need for additional software purchases and ensuring a seamless user experience.

The Open Builds Black Box supports various CNC machine types, including routers and kits, providing versatility for different project needs. Whether you’re working on a small-scale hobby project or a large-scale professional undertaking, the Black Box offers the features and customization options required to achieve accurate and high-quality results.

Key Features of the Open Builds Black Box:

- Integrated motion controller and board for CNC machines

- Compact design for easy installation and operation

- USB port for seamless connection and communication

- Included control software for a streamlined user experience

- Compatibility with various CNC machine types

- Customization options for precise control and operation

The Open Builds Black Box is a reliable and efficient solution for all your CNC machine needs. Its user-friendly design and comprehensive features make it an excellent choice for both beginners and experienced CNC enthusiasts.

Setting Up the Open Builds Black Box

Setting up the Open Builds Black Box is remarkably simple thanks to its plug and play functionality. With just a few easy steps, you’ll have your Black Box up and running in no time.

When you unbox your Open Builds Black Box, you’ll notice a QR code that provides comprehensive instructions for the setup process. Simply scan the code with your smartphone or tablet to access the setup instructions.

Follow the instructions provided in the QR code and refer to the wiring diagram specific to your servo motors. This will guide you in wiring up the motor connections correctly, ensuring smooth operation of your CNC machine.

The Open Builds Black Box comes complete with all the necessary plugs, making the connection process hassle-free. Simply match the corresponding plugs with their respective ports and securely insert them. The intuitive design of the Black Box makes it easy to connect all the components.

By following these straightforward steps and utilizing the provided instructions, you can assemble and set up your Open Builds Black Box quickly and effortlessly.

For a visual reference, take a look at the diagram below:

Assembling the Open Builds Black Box is uncomplicated, allowing you to focus on your CNC projects without unnecessary delays or confusion.

Connecting and Wiring the Servo Motors

Connecting and wiring the servo motors to the Open Builds Black Box is a straightforward process. By following the instructions provided on the front panel of the Black Box, you can ensure a proper and accurate wiring setup. The front panel clearly illustrates the different terminals and wires, making it easy to identify and connect each component.

To wire the servo motors, refer to the specific wiring diagram provided for your servo motors. This diagram will guide you in connecting the wires to the correct terminals on the Black Box. By wiring them up correctly, you ensure compatibility and achieve optimal performance from your servo motors.

Take a look at the diagram below for a visual representation of the wiring setup:

Servo Motor Wiring Diagram

By carefully following the instructions and using the wiring diagram as a reference, you can confidently connect and wire your servo motors to the Open Builds Black Box. This step is crucial for the proper functioning of your CNC machine, ensuring smooth and precise movements during operation.

Powering the Open Builds Black Box

Powering the Open Builds Black Box is a straightforward process that requires a few simple steps. To get started, you will need a power supply that meets the specific requirements of the Black Box. The power supply should have a 110-volt input and provide a 24-volt output. Once you have the appropriate power supply, follow these steps:

- Connect the power supply to the Open Builds Black Box.

- Plug in your servo motors to the designated motor connectors on the Black Box.

- Connect the Black Box to your computer using the USB cord provided.

With all the necessary connections in place, you are now ready to power up the Open Builds Black Box and start utilizing its features for your CNC machine.

| Process | Description |

|---|---|

| 1. Connect the power supply | Use a power supply with a 110-volt input and 24-volt output to connect to the Open Builds Black Box. |

| 2. Plug in the servo motors | Connect your servo motors to the designated motor connectors on the Black Box for power and control. |

| 3. Connect to the computer | Establish a connection between the Black Box and your computer using the provided USB cord. |

| 4. Power up the Black Box | Once all connections are secure, power up the Open Builds Black Box to activate its functionality. |

Using the Open Builds Control Software

The Open Builds Black Box comes with its own control software, known as the Open Builds Control. With this software, you can easily convert your projects into G-code, the programming language used by CNC machines. By converting your project into G-code, you gain full control over your CNC machine using the Open Builds Black Box.

The Open Builds Control software simplifies the process of generating G-code, making it accessible to users of all skill levels. Whether you’re a beginner or an experienced CNC enthusiast, this software provides a user-friendly interface that allows you to easily run and control your CNC machine.

By following the step-by-step tutorial provided by Open Builds, you can quickly learn how to navigate the Open Builds Control software and unlock its full potential. The tutorial covers everything from importing your project files to configuring the toolpaths and running the CNC machine.

With the Open Builds Control software, you have the power to bring your designs to life with precision and efficiency. Whether you’re creating intricate woodwork or intricate metal parts, this software ensures that your CNC machine operates smoothly and accurately.

Benefits of Using the Open Builds Control Software

- Easy project conversion into G-code

- User-friendly interface for CNC machine control

- Accessible to users of all skill levels

- Precise and efficient operation

- Smooth and accurate results

With the Open Builds Control software, you can unleash the full potential of your CNC machine and take your projects to the next level.

Comparing the Open Builds Control Software with Mach 3 and Mach 4

When it comes to CNC software options, Open Builds Control software stands out with its user-friendly experience and hassle-free setup. While it may not offer the same versatility as Mach 3 or Mach 4, Open Builds Control software provides a straightforward solution for beginners and individuals who prioritize quick results without intricate configurations.

Unlike Mach 3 and Mach 4, which require significant time investment and technical know-how, Open Builds Control software is designed to be plug and play. This means users can seamlessly install and start using the software without the complexities associated with other options.

By prioritizing simplicity, Open Builds Control software streamlines the CNC process, allowing users to focus on their projects rather than navigating convoluted settings. Its intuitive interface and user-friendly features make it an excellent choice for those seeking efficiency and ease of use.

| Comparison | Open Builds Control Software | Mach 3 | Mach 4 |

|---|---|---|---|

| Setup Complexity | Plug and play simplicity | Requires configuration and technical expertise | Requires configuration and technical expertise |

| User Experience | Intuitive and beginner-friendly | Extensive customization options | Extensive customization options |

| Time Investment | Quick and efficient setup | Time-consuming configuration process | Time-consuming configuration process |

The table above summarizes some key aspects of the Open Builds Control software in comparison to Mach 3 and Mach 4. While the latter options provide advanced customization features, Open Builds Control software offers a streamlined experience that caters to users who value simplicity and quick results.

Benefits of the Open Builds Black Box

The Open Builds Black Box provides several advantages for CNC machine builders and enthusiasts. With its plug and play functionality, the Black Box offers a quick and easy setup process, saving valuable time and effort. Whether you’re a beginner or an experienced builder, the convenience of the Black Box ensures a hassle-free experience.

One of the key benefits of the Open Builds Black Box is its cost-effectiveness. By including all the necessary components in a single package, the Black Box eliminates the need to purchase multiple individual parts. This not only streamlines the building process but also reduces the overall cost of creating or converting a CNC machine.

Let’s take a closer look at the benefits:

- Plug and play functionality for easy setup

- Cost-effective solution with all-in-one components

By choosing the Open Builds Black Box, you can simplify your CNC machine building journey while enjoying the convenience and affordability it offers.

Limitations of the Open Builds Black Box

Although the Open Builds Black Box offers numerous benefits, it is important to consider its limitations before making a purchasing decision. One notable limitation is its lack of adaptability compared to software like Mach 3 and Mach 4. While the Open Builds Control software is more straightforward and user-friendly, it may not offer the same level of customization and advanced features as its counterparts.

Individuals with specific requirements or advanced machining needs might find the Open Builds Black Box limiting in terms of functionality. The software’s simplicity and ease of use make it a great choice for beginners and those who prioritize a hassle-free setup. However, for those seeking more advanced capabilities, alternative software options like Mach 3 and Mach 4 might be preferable.

Despite this limitation, the Open Builds Black Box remains a reliable and cost-effective solution for many CNC machine builders and enthusiasts. Its plug and play functionality, combined with its all-in-one design, makes it an attractive option for those looking to save time and money by avoiding the need to purchase multiple individual components. However, it’s essential to carefully assess your specific needs and evaluate whether the Open Builds Black Box aligns with your requirements.

Future Videos and Updates

In our upcoming videos, we are thrilled to showcase an exciting project: converting a quilting machine into a CNC quilting machine using the Open Builds Black Box. This unique application brings together the worlds of quilting and CNC technology, appealing to individuals who want to combine their passion for both crafts. With the Open Builds Black Box, this transformation becomes accessible and affordable, opening up new possibilities for quilting enthusiasts.

Stay tuned for more captivating videos and updates as we explore the process of converting a quilting machine into a CNC quilting machine with the help of the Open Builds Black Box. Discover how this innovative solution revolutionizes the quilting experience, empowering creators to bring intricate designs to life with precision and efficiency.

Open Builds Black Box – Key Features

| Feature | Description |

|---|---|

| Compact Design | The Open Builds Black Box is an all-in-one motion controller board that combines board and motion controllers into a single unit, providing convenience and ease of use. |

| USB Port | The Black Box includes a USB port for seamless control and communication, allowing for easy connection to your computer or other devices. |

| Plug and Play Functionality | Setting up the Black Box is a breeze thanks to its plug and play functionality. Simply follow the provided instructions for a quick and hassle-free setup process. |

| Comprehensive Control Software | The Open Builds Black Box comes with its own control software, simplifying the process of converting your projects into G-code and controlling your CNC machine. |

| Wide Compatibility | The Black Box is compatible with various CNC machine types, allowing for versatility and adaptability in your projects. |

| Affordable Solution | With the Open Builds Black Box, you get all the necessary components in one package, providing a cost-effective solution for building or converting a CNC machine. |

Celebrating 10 Years of Innovation with OpenBuilds

OpenBuilds is proud to celebrate its 10th anniversary, marking a decade of innovation, empowerment, and creative exploration in the DIY manufacturing world. As pioneers in this industry, OpenBuilds has redefined flexibility, collaboration, and the potential of creation.

One of the key factors contributing to OpenBuilds’ success is its vibrant community of like-minded enthusiasts who share a passion for innovation and ingenuity. This community has flourished over the years, connecting individuals around the globe who are driven by the spirit of making and pushing boundaries.

In 2013, OpenBuilds introduced the revolutionary V-Slot Linear Rail, a game-changer in precision engineering for DIY CNC and 3D printing. This breakthrough technology sparked a global movement of makers and inventors realizing their ideas with unparalleled precision and accuracy.

The legacy of OpenBuilds continues to inspire and empower DIY enthusiasts, providing them with the tools and resources needed to bring their visions to life. With a wide range of OpenBuilds CNC machines and a dedicated community, OpenBuilds is at the forefront of DIY fabrication, driving innovation and creativity forward.