BigRep offers a range of large-format 3D printing solutions designed for industrial applications, prototyping, and production. Their flagship models include the BigRep ONE, PRO, STUDIO G2, and ALTRA 280, each catering to different needs and budgets. These printers feature massive build volumes up to one cubic meter, allowing for the creation of full-scale parts and prototypes. BigRep’s machines utilize advanced extrusion technology, open-source materials, and intelligent software solutions to deliver high-quality, large-scale 3D prints.

The company’s printers are used across various industries, including automotive, aerospace, and design, for applications such as functional prototyping, tooling, and end-use parts production. BigRep also provides comprehensive support, training, and an on-demand 3D printing service called Partlab for businesses that need large-format 3D printed parts without investing in their own equipment.

- BigRep specializes in large-format 3D printing solutions for industrial applications.

- Their printers are ideal for rapid prototyping, custom manufacturing, and more.

- BigRep offers a wide selection of materials for various projects.

- Their technology enables precise and functional parts on a large scale.

- With BigRep, you can bring your designs to life with ease and efficiency.

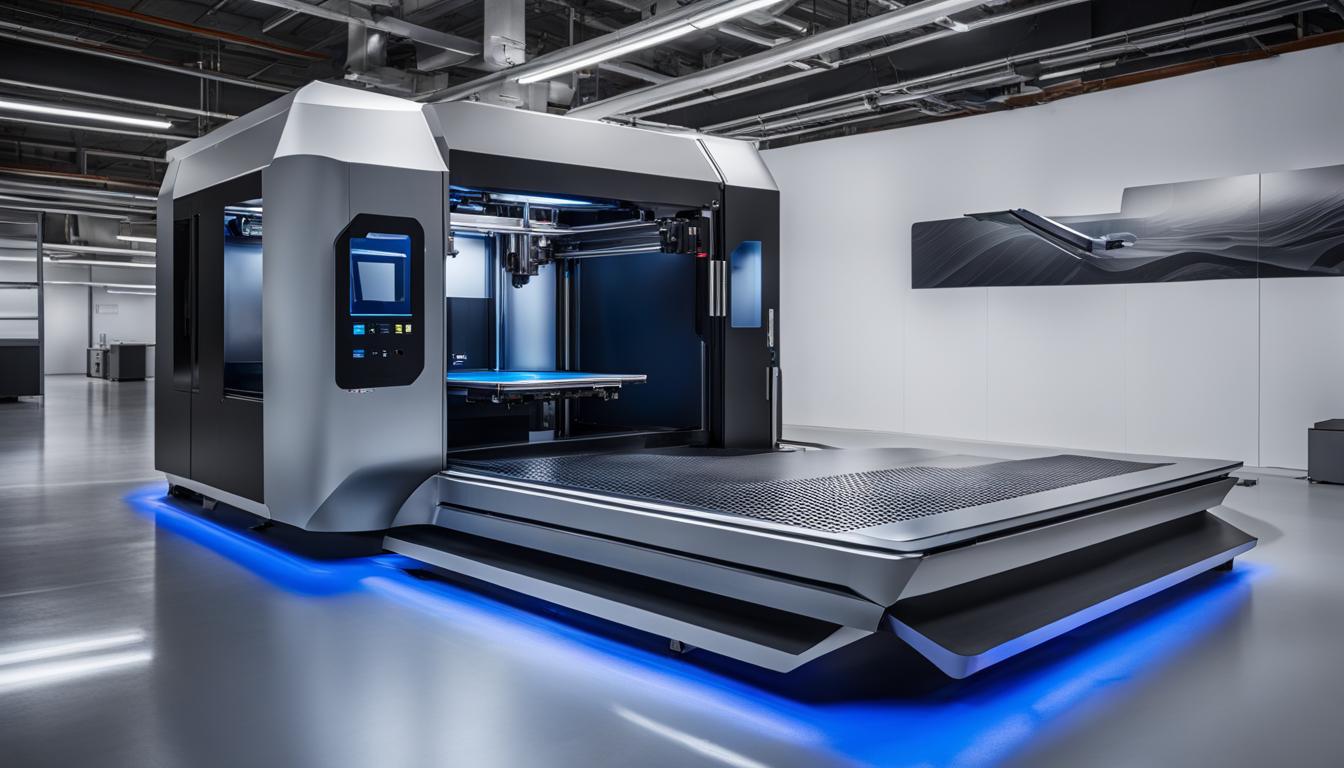

BigRep PRO – Scalable Solution for Manufacturing

The BigRep PRO is an advanced industrial 3D printer that offers a highly scalable solution for a wide range of manufacturing needs. With its robust construction and impressive capabilities, the BigRep PRO is the go-to choice for prototyping and production in various industries.

One of the standout features of the BigRep PRO is its large build volume of 1 m³, allowing for the creation of full-scale parts and prototypes. This spacious build area provides ample space for producing large and complex designs, making it ideal for industrial applications.

The BigRep PRO is built to deliver accurate and precise parts consistently. Using engineering-grade materials, this 3D printer ensures the creation of high-quality components that meet industry standards. It offers exceptional dimensional accuracy and surface finish, making it perfect for projects that require fine details and intricate geometries.

As a versatile manufacturing tool, the BigRep PRO offers remarkable speed and efficiency. It produces parts at a faster rate compared to traditional manufacturing methods, reducing lead times and accelerating production cycles. This allows manufacturers to meet tight deadlines and deliver products to market faster.

Key Features of the BigRep PRO

- Scalable and customizable manufacturing solution

- 1 m³ build volume for full-scale production

- Precision and accuracy for engineering-grade parts

- Fast and efficient printing for rapid production cycles

- Compatibility with a wide range of engineering-grade materials

- Easy operation and user-friendly interface

With the BigRep PRO, companies can optimize their production processes and reduce costs. The use of additive manufacturing technology eliminates the need for expensive tooling and reduces material waste. This not only contributes to cost savings but also minimizes the environmental impact associated with traditional manufacturing methods.

Whether you’re in the prototyping phase or ready for full-scale production, the BigRep PRO is an industrial 3D printer that delivers exceptional results. Its scalability, accuracy, and production efficiency make it a valuable asset for businesses in various sectors, including automotive, aerospace, consumer goods, and more.

Investing in the BigRep PRO means gaining a competitive edge in the industry. It empowers engineers and designers to bring their innovative ideas to life, enabling them to create functional prototypes and end-use parts with ease. The BigRep PRO is the ultimate solution for companies seeking to optimize their manufacturing processes and stay ahead in today’s rapidly changing market.

| Advantages of the BigRep PRO | Traditional Manufacturing Methods |

|---|---|

| Fast production cycles | Long lead times |

| Lower production costs | Expensive tooling |

| Accurate and precise parts | Dimensional variations |

| Reduced material waste | Material scrap |

| Flexibility in design iterations | Limited design modifications |

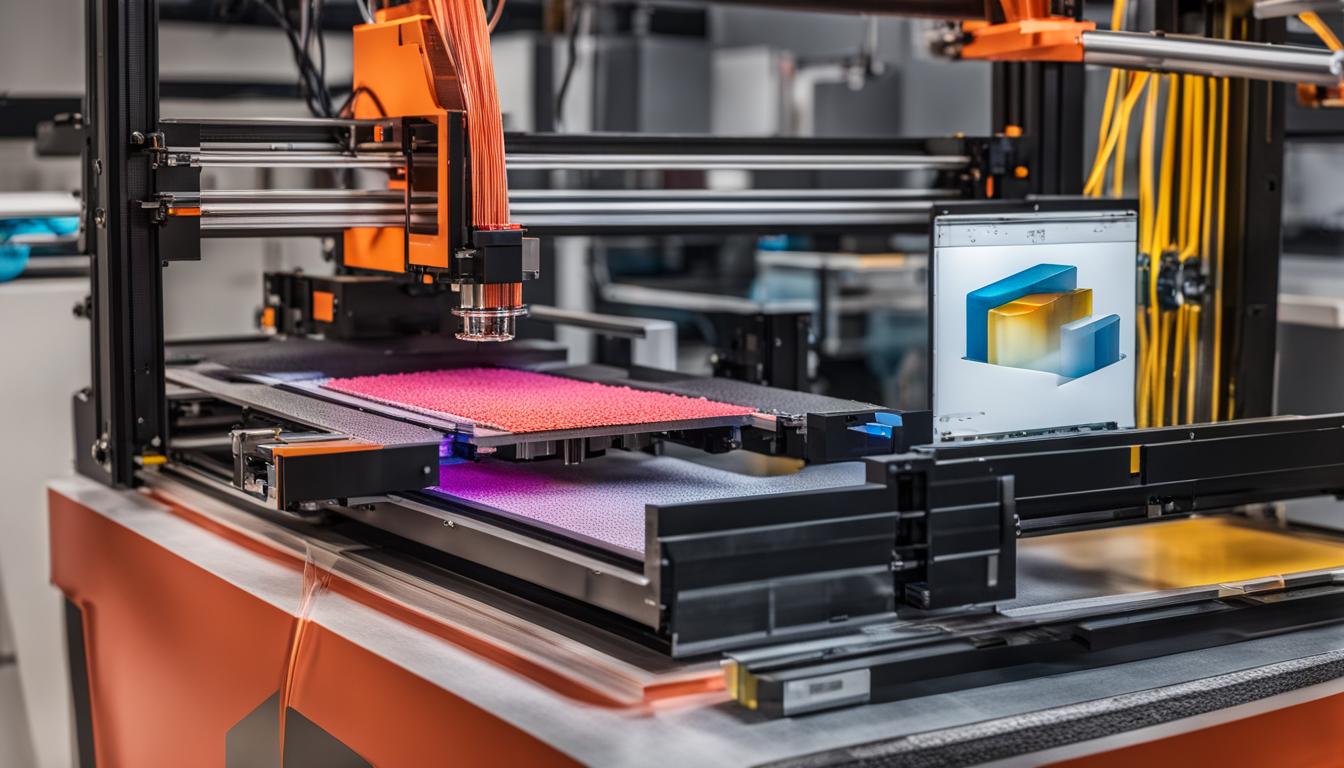

BigRep STUDIO G2 – Large-Scale Industrial Manufacturing

The BigRep STUDIO G2 is a game-changer in the world of large-scale industrial manufacturing. This desktop 3D printer offers unprecedented build volume, making it a powerful tool for producing industrial-grade parts. Despite its compact design, the STUDIO G2 delivers the capabilities of much larger industrial printers, revolutionizing the way manufacturers approach production.

With a build volume that is 10 times larger than traditional desktop 3D printers, the STUDIO G2 enables businesses to create big and complex parts in a single print job. Whether it’s prototyping or producing end-use components, this printer can handle it all without compromising on precision and quality.

The STUDIO G2’s compact design is a game-changer for industrial manufacturing. It opens up new possibilities, allowing businesses to integrate 3D printing directly into their production lines, minimizing downtime and maximizing efficiency. Its small footprint makes it easy to fit into any workspace, making it an ideal choice for manufacturers of all sizes.

The Benefits of the BigRep STUDIO G2

- Unmatched build volume: The STUDIO G2 offers an expansive build volume, allowing for the production of large-scale industrial parts in a single print job.

- Efficient workflow: With its compact design, the STUDIO G2 seamlessly integrates into existing production lines, streamlining manufacturing processes.

- High-quality output: The STUDIO G2 ensures exceptional print quality and accuracy, delivering industrial-grade parts that meet the strictest standards.

- Wide range of materials: This printer supports a variety of engineering-grade materials, providing flexibility and versatility in material selection.

- User-friendly operation: Despite its industrial capabilities, the STUDIO G2 is easy to operate, making it accessible to both experienced professionals and beginners.

The BigRep STUDIO G2 is revolutionizing the way industrial manufacturing is approached. Its combination of a compact design and large build volume makes it a truly unique solution for businesses looking to enhance their production capabilities. Whether it’s rapid prototyping, tooling, or end-use parts, the STUDIO G2 delivers exceptional results with reliability and precision.

BigRep ONE – Award-Winning Large-Format 3D Printer

The BigRep ONE is an award-winning large-format 3D printer known for its accessibility and versatility. Trusted by designers, innovators, and manufacturers worldwide, this printer is a true game-changer in the industry.

With its impressive one-cubic-meter build volume, the BigRep ONE allows for full-scale 3D printing of designs, giving you the freedom to bring your vision to life on a grand scale. Whether you are working on architectural models, prototypes, or intricate structures, the ONE delivers exceptional precision and creativity.

One of the standout features of the BigRep ONE is its accessible price point, making advanced large-format 3D printing technology more attainable than ever before. This printer offers professional-grade performance without breaking the bank, opening up new possibilities for businesses and individuals alike.

Design innovation is at the heart of the BigRep ONE, which is continuously pushing the boundaries of what can be achieved with 3D printing. From complex geometries to functional prototypes, this printer delivers exceptional quality and detail, ensuring that your finished products exceed expectations.

| Key Features of the BigRep ONE: |

|---|

| Massive one-cubic-meter build volume |

| Accessible price point |

| Precision and detail for full-scale 3D printing |

| Advanced design innovation capabilities |

Understanding 3D Printing Technology

3D printing, also known as additive manufacturing, is a revolutionary technology that enables the creation of three-dimensional objects using plastic polymer materials (and occasionally metals). This process involves translating digital designs, created using Computer-Aided Design (CAD) software, into physical objects by printing layer upon layer.

Through the use of CAD models, 3D printing offers endless possibilities for customization and precision in manufacturing. It eliminates the need for traditional subtractive processes and allows for the creation of complex structures that would otherwise be impossible or time-consuming to produce.

There are several types of 3D printing technologies available, each with its own unique advantages and applications. Let’s take a closer look at three popular methods:

Fused Filament Fabrication (FFF)

FFF, also known as Fused Deposition Modeling (FDM), is the most common and affordable form of 3D printing. It works by melting plastic filament and precisely depositing it layer by layer to build the object. This technology is widely used in various industries and is especially popular among hobbyists and small-scale productions.

Stereolithography (SLA)

SLA is a high-resolution 3D printing technique that uses liquid photopolymer resin. The resin is cured layer by layer using a UV laser, resulting in highly detailed and accurate prints. SLA is frequently employed in applications that require intricate details, such as jewelry making, dental models, and architectural prototypes.

Selective Laser Sintering (SLS)

SLS is a powerful 3D printing technology that utilizes powdered materials, such as plastics or metals. A laser selectively fuses the powder particles together, layer by layer, to create a solid object. SLS is known for its ability to produce complex geometries and functional parts. It is widely adopted in industries like aerospace, automotive, and healthcare.

These advanced 3D printing technologies continue to evolve, opening up new opportunities for innovation and manufacturing efficiency. They are revolutionizing industries by significantly reducing lead times, minimizing material waste, and enabling complex geometries that were previously unattainable.

How Different 3D Printing Technologies Work

When it comes to 3D printing, there are several technologies available, each with its unique process and applications. Let’s explore three popular 3D printing technologies: Fused Filament Fabrication (FFF), Stereolithography (SLA), and Selective Laser Sintering (SLS).

Fused Filament Fabrication (FFF)

Fused Filament Fabrication, also known as Fused Deposition Modeling (FDM), is the most common and affordable form of 3D printing technology. It works by depositing molten filament layer by layer until the desired object is formed. The filament is heated and extruded through a nozzle, which moves along the x, y, and z axes to create the object. FFF technology is widely used for rapid prototyping, small-scale production, and hobbyist applications due to its ease of use and cost-effectiveness.

Stereolithography (SLA)

Stereolithography uses a different approach to 3D printing. It involves a liquid resin that is cured by a UV laser, layer by layer, to create the object. The printer’s build platform lowers with each cured layer, gradually building the entire object. SLA technology offers high resolution and is capable of producing highly detailed parts, making it popular in industries such as jewelry, dentistry, and engineering. However, SLA 3D printing typically requires more material and can be slower compared to other technologies.

Selective Laser Sintering (SLS)

Selective Laser Sintering is a 3D printing technology commonly used for metal additive manufacturing. It works by using a high-powered laser to selectively heat and fuse powdered material (such as plastic or metal) layer by layer until the object is complete. The powdered material is spread in a thin layer, and the laser sinters the areas defined by the CAD model, solidifying them. SLS is known for its versatility and ability to produce complex geometries and functional parts. It is commonly used in industries such as aerospace, automotive, and healthcare.

Each of these 3D printing technologies offers unique advantages and applications. The choice of technology depends on factors such as the desired resolution, material, time, and budget constraints. Now that we have explored these technologies, let’s delve further into the three steps involved in 3D printing.

The 3 Steps of 3D Printing

3D printing is a multi-step process that involves design, 3D printing, and post-processing. Each step plays a crucial role in bringing ideas to life and creating high-quality 3D printed objects.

1. Design

The first step in the 3D printing process is design. It involves creating a digital model of the object you want to print using Computer-Aided Design (CAD) software. CAD software allows you to design intricate and complex shapes with precision. You can choose from a wide range of design options and customize your model according to your specific requirements.

During the design phase, you have the freedom to experiment with different shapes, sizes, and features to achieve the desired outcome. You can also make modifications and adjustments to your design before moving on to the next step.

2. 3D Print

After finalizing your design, the next step is to prepare it for 3D printing. This involves converting your digital model into G-code instructions that can be understood by the 3D printer. G-code is a programming language that tells the 3D printer how to move, extrude filaments, and create layers to build the object layer by layer.

During the 3D printing process, the printer carefully builds the object by depositing layers of material one on top of another. The choice of material depends on the specific requirements of your design. It could be plastic, metal, or even composite materials for more advanced applications.

While the 3D printer does the work, it’s important to monitor the printing process to ensure the object is being printed accurately and without any errors. This step requires patience and attention to detail, as it can take some time depending on the size and complexity of the object.

3. Post-Process

Once the 3D printing is complete, the final step is post-processing. This step involves removing any support structures used during the printing process and applying any necessary finishing touches to the object. The goal of post-processing is to refine the object, improve its appearance, and enhance its functionality.

The specific post-processing techniques can vary depending on the material and design of the printed object. It may include sanding, polishing, painting, or even applying a protective coating. Some objects may require additional curing or heat treatment to achieve the desired properties.

Post-processing is an important step to ensure the final 3D printed object meets or exceeds the desired quality standards. It allows for fine-tuning and refinement, resulting in a finished product that is ready for use or further integration into a larger project.

Advantages of 3D Printing

3D printing offers several advantages over traditional manufacturing technologies. Let’s explore how this innovative approach to production can bring speed, flexibility, cost-efficiency, and environmental friendliness to your projects.

1. Speed

One of the major benefits of 3D printing is its speed. Unlike conventional manufacturing methods that may involve lengthy setup times and complex processes, 3D printing allows for the rapid production of complex objects in a shorter time frame. This speed can significantly reduce the time it takes to bring your ideas to life, enabling faster prototyping, iteration, and production.

2. Flexibility

With 3D printing, you can enjoy unparalleled flexibility throughout the manufacturing process. Unlike traditional methods that require physical tooling and molds, 3D printing eliminates the need for costly and time-consuming setups. This means that design changes can be easily accommodated, allowing for greater creativity and the exploration of new possibilities. From customized products to intricate designs, 3D printing offers the flexibility to bring your vision to reality with ease.

3. Cost Efficiency

When it comes to cost, 3D printing offers a highly efficient solution. Unlike traditional manufacturing techniques that often involve wasteful processes and the use of excess materials, 3D printing uses only the material needed for the object being produced. This not only reduces material costs but also minimizes waste. Additionally, 3D printing eliminates the need for manual labor-intensive steps, further reducing production costs. The result is a cost-effective manufacturing solution that can help you optimize your budget and maximize your resources.

4. Environmental Friendliness

Another significant advantage of 3D printing is its positive impact on the environment. By reducing material waste and optimizing resource usage, 3D printing minimizes the environmental footprint of manufacturing processes. Additionally, the ability to produce objects on-demand and locally reduces the energy consumption associated with transportation and logistics. With 3D printing, you can embrace a more environmentally friendly approach to manufacturing.

As you can see, 3D printing offers a multitude of advantages that can revolutionize the way you approach manufacturing. From speed and flexibility to cost efficiency and environmental friendliness, this innovative technology opens up new possibilities for design, prototyping, and production. Embrace the future of manufacturing with the power of 3D printing.

BigRep’s 3D Printing Service – Bringing Your Ideas to Life

BigRep offers a comprehensive 3D printing service through Partlab, making it easier than ever to bring your ideas to life. With our online platform, you can conveniently order large-format 3D printed parts and have them delivered right to your doorstep. No matter the size or complexity of your project, our service provides access to massive build volumes, ensuring that even the largest designs can be realized.

One of the biggest advantages of our 3D printing service is the wide range of materials available. We offer a diverse selection of high-quality 3D printing filaments, allowing you to choose the perfect material for your specific application. From durable plastics to advanced composites, our materials ensure that your 3D printed parts meet the highest standards of strength, flexibility, and performance.

At BigRep, we understand the importance of affordability without compromising on quality. That’s why our pricing is competitive, making our 3D printing service accessible to both individuals and businesses. From prototypes to end-use parts, we offer cost-efficient solutions that meet your needs and budget.

With our team of experts, you can trust that your 3D printed parts will be produced with the utmost precision and expertise. Our experienced technicians have a deep understanding of additive manufacturing and can offer valuable insights and guidance throughout the process. Whether you’re a design professional or a first-time 3D printer user, we’re here to support you every step of the way.