Can you mill aluminum with a router?

Yes, you can mill aluminum with a router. Aluminum is a softer metal, so it’s suitable for machining with a router. When milling aluminum with a router, you’ll need a few special considerations.

First, make sure that your router has enough torque and power to handle the job. Aluminum is a soft metal and will require more power than a router designed for woodworking. Second, select a router bit specifically designed for milling aluminum. You’ll need to invest in higher quality router bits and choose one that has a sharper edge, as aluminum is a more delicate metal than wood.

Third, consider the speed that your router operates at. Aluminum needs to be machined at a slower speed than wood in order to prevent melting. Fourth, make sure to use plenty of lubrication and use cutting fluids, such as mineral oils, to reduce friction and heat buildup. Finally, apply light downward pressure when milling aluminum with a router.

Overall, it is possible to mill aluminum with a router, but it requires special considerations. Investing in a router specifically designed for the job, as well as quality router bits, is a must. Make sure to adjust the speed, use lubrication and light downward pressure, and be sure to use appropriate cutting fluids to help get the job done.

Can a router be used for milling?,Can you use a mill on wood?

But to answer your question, yes, you can work aluminum with a router. For what you are trying to do, I would start by cutting a dado in a piece of hardwood exactly the size of your aluminum stock. Wood in a mill also carries the same concerns that any other wood cutting tool might. For instance, wood dust is combustible, so it’s recommended to have a dust collection system of some sort if you’re going to be doing a lot of wood cutting. Probably the most surprising con to cutting wood is how it wears tools.

Are CNC routers worth it?

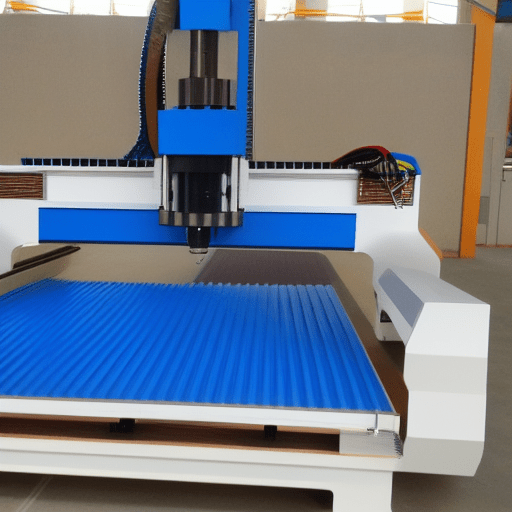

The answer to whether or not CNC routers are worth it depends on your individual needs. For the hobbyist or small shop, a CNC router can increase production speed, accuracy, repeatability, and reduce material waste. This can significantly reduce material costs and labor costs as well. CNC routers are also perfect for automated production when used in conjunction with other automated equipment.

For larger production runs, CNC routers can substantially increase production speed and accuracy when compared to manual machining. Likewise, CNC routers can significantly reduce the risk of human error. CNC routers are also extremely efficient, allowing you to set a single tool path for multiple parts, which can reduce dramatically reduce menial tasking and labor costs.

In terms of time savings, a CNC router can be incredibly cost-effective. A single CNC router can work tirelessly on a job, eliminating the need for setups and additional labor. Additionally, CNC routers are able to run without breakage or fatigue, which can help to keep down costs associated with machine maintenance, not to mention reducing labor costs over the course of a job.

Overall, CNC routers can be a great asset to any shop, depending on their needs. If you have a large volume of parts or require high precision, CNC routers are a great investment. They can help to reduce both time and money, due to their accuracy and efficiency. In short, CNC routers are absolutely worth the investment.

What is the difference between CNC milling and routing?

CNC milling and routing are both machining processes that use cutting tools to precisely remove material from a raw piece to produce a finished product. However, there are some major differences between the two processes.

CNC Milling utilizes rotating cutters to remove material from the piece being machined. The cutting tool moves in multiple axes in order to remove material evenly in a controlled manner. The cutting tool can move in the x, y, and z directions and is beneficial when cutting complex shapes, profiles, and threads. CNC milling is used in the manufacture of a wide range of parts, components, and products and is often used to mill precision shapes and components from metals, composites, and plastics.

CNC routing is a machining process that uses a series of cutters on a moving drill bit to cut an object. Unlike CNC milling, CNC routing utilizes a router bit that remains stationary and is then fed into the material to create a shape or pattern. Routing is typically used for cutting softer plastics and woods, where the cut does not need to be as precise as it would be with milling. CNC routing is often used to cut patterns and complex designs with intricate details.

Overall, the main difference between CNC milling and routing is the type of tooling and the type of material being cut. CNC milling relies on a rotating cutting tool to produce precise shapes and parts from a variety of metals and plastics. By contrast, routing utilizes a stationary router bit to cut softer materials, such as wood and plastic, and is utilized for producing intricate designs and patterns. Each processes has its own uses and benefits, so it is important to consider which is the right fit for a particular application.

Can you router stainless steel?

Routing stainless steel is possible but requires special tools, patience, and knowledge. A router is a power tool that’s most often used to cut and shape wood, but with the right attachments it can also be used to carve and shape metal.

When routing stainless steel, it’s important to use the right type of router bit. Since stainless steel is harder than wood, standard wood router bits don’t have the necessary cutting strength. Instead, use a carbide-tipped router bit, so called because it has a tip made of carbide, a compound composed of equal parts of carbon and tungsten.

You’ll also need to adjust the speeds and feeds on your router. In other words, adjust the speed of the tool and the feeds, or the rate at which it moves through the steel. Generally, a router should travel no more than half the speed it would for wood. And reducing the feed rate helps ensure that the bit doesn’t overheat.

Finally, making sure everything is properly lubricated is especially important. The lubricant helps reduce the heat build up and makes it easier for the bit to cut through the steel. You can use either a water-based lubricant or an oil-based lubricant, depending on your preferences and the application.

Routing stainless steel may require more effort, but with the right equipment and knowledge it can be done. Taking the time to properly adjust your router will result in a cleaner, more precise cut — and that makes all the difference.

Can you use a router bit in a drill?

Yes, you can use a router bit in a drill, but it is important to note that not all drills are suitable for this. If you are looking to use a router bit in a drill, it is best to use a variable speed, corded drill that runs from 0–2000 RPM. The drill must also be sturdy and well–balanced to ensure that the router bit does not slip. It is also important to make sure that the drill is equipped with a chuck and locking key. This will enable you to securely fasten the router bit in place and prevents it from coming loose. Additionally, it is also important to ensure that the drill is suitable for the material that you are working with.

When using a router bit in a drill, you should never use a hammer action or high–torque setting. This can cause excessive vibration which can damage the bit. To further prevent damage to the router bit, it is best to decrease the drill’s speed when using the bit. This will help ensure that the bit stays sharp and prevents the drill from becoming too hot. As a safety precaution, you should always wear protective eye and ear wear when using a router bit in a drill. Additionally, it is best to hold the drill firmly with both hands to ensure that it doesn’t slip as you work.

What speed should you mill aluminum?

The basic calculation to find a starting point for RPMs would be (3.82 x SFM) / Diameter. In wrought aluminum alloys (i.e. 2024, 6061, 7075), a surface footage of 800-1500 SFM is recommended, with the same calculation being used to find a starting point for RPMs.

What type of cutter is used for milling aluminum?

Milling aluminum is a delicate operation, as the metal is soft and easy to damage. As a result, a specialized cutter must be used in order to avoid damaging the material. The most common type of cutter used for milling aluminum is a ball end mill. This type of cutter has a spherical tip that helps to minimize the chances of damaging the edges of the aluminum. In addition, ball end mills are able to create a smooth finish on the surface of the aluminum. As a result, they are the preferred type of cutter for milling aluminum.

How much does it cost to mill aluminum?

The cost of milling aluminum depends on several factors including the scale and complexity of the milling project. For most small–scale projects, such as a few parts or simple model components, the cost is usually relatively low and can range between $0.30 and $2.00 per part. For larger projects and more complex parts, the cost of aluminum milling can range between $3.00 and $10.00 per part or higher. Additionally, the cost of milling aluminum depends on the complexity of the part, the size and finishes required, the type of milling machine required, and the level of quality control needed. For instance, if you are producing parts with tight tolerances, intricate details, high–level surface finishes, or special coatings, the cost of the project will be higher.

Furthermore, if more complex milling systems and machines are needed, along with multiple steps and specialized cutting tools and accessories, then the cost may increase even further. In most cases, the cost of milling aluminum is determined by a combination of material cost, cutting tools and machines, labor, and overhead expenses for the shop or workshop. This means that the total cost of milling aluminum is dependent on the specific criteria of the project and should be discussed in detail with a supplier or machinist before any commitment is made.

How do you CNC Aluminium?

CNC Router Aluminum Cutting: 11 Easy TipsDon’t be in a hurry. … Use a Feeds and Speeds Calculator. … Use CNC Router Bits for cutting aluminum (carbide endmills) … Use smaller diameter cutters. … Be paranoid about clearing chips. … Watch cut depths and slotting–they make it harder to clear chips. … Lubricate with a Mist.

Can you cut aluminum with woodworking tools?

Many of these could benefit from the speed and precision of our woodshop equipment, but you might be unsure if it’s safe to work metal with your woodworking tools. One of the common items that comes up is whether cutting aluminum with a table saw is safe. Thankfully, the answer is a qualified yes.