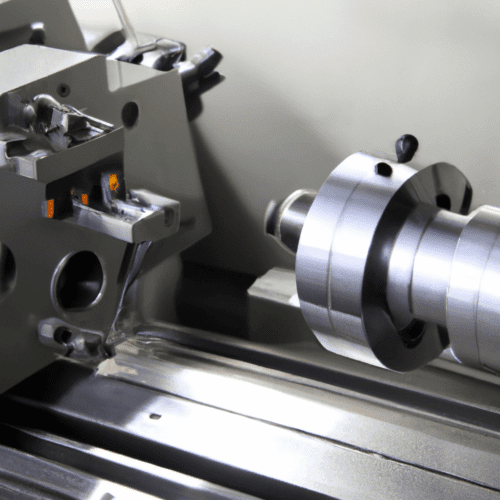

The CNC lathe is a computer-controlled machine tool that is used to shape metal and other materials into a variety of shapes and sizes. It is a highly precise and automated machine that can produce complex parts with a high degree of accuracy and repeatability. The advantages of using a CNC lathe include:

1. Increased Productivity: CNC lathes are able to produce parts quickly and accurately, which increases productivity and reduces costs. The machine can be programmed to produce multiple parts in a single setup, which eliminates the need for multiple setups and reduces the amount of time needed to produce a part.

2. Increased Accuracy: CNC lathes are able to produce parts with a high degree of accuracy and repeatability. This is due to the fact that the machine is programmed with precise instructions and is able to follow them precisely. This eliminates the need for manual adjustments and ensures that the parts produced are of the highest quality.

3. Reduced Labor Costs: CNC lathes are able to produce parts with minimal human intervention, which reduces labor costs. The machine is able to run unattended for long periods of time, which eliminates the need for additional labor.

4. Increased Versatility: CNC lathes are able to produce a wide variety of parts with different shapes and sizes. This allows for greater flexibility in the production process and allows for the production of parts that would otherwise be difficult or impossible to produce with traditional machining methods.

5. Reduced Waste: CNC lathes are able to produce parts with minimal waste, which reduces costs and increases efficiency. The machine is able to produce parts with a high degree of accuracy and repeatability, which eliminates the need for additional material and reduces the amount of scrap produced.

What are the advantages & disadvantages of CNC machine?

Advantages of CNC Machines:

1. Increased Accuracy: CNC machines are capable of producing high-precision components with a high degree of accuracy. This is because the machines are programmed with precise instructions and can repeat the same operation multiple times with the same results.

2. Increased Productivity: CNC machines are capable of producing components at a much faster rate than manual machines. This is because the machines are programmed to perform multiple operations at once, which reduces the amount of time needed to complete a job.

3. Reduced Labor Costs: CNC machines require fewer operators than manual machines, which reduces labor costs. This is because the machines are programmed to perform multiple operations at once, which reduces the amount of time needed to complete a job.

4. Reduced Waste: CNC machines are programmed to produce components with a high degree of accuracy, which reduces the amount of waste produced. This is because the machines are programmed to produce components with a high degree of accuracy, which reduces the amount of waste produced.

Why are CNC machines important?

CNC (Computer Numerical Control) machines are important because they allow for the automation of complex manufacturing processes. CNC machines are programmed with a set of instructions that tell the machine how to move and what operations to perform. This allows for the production of parts with a high degree of accuracy and repeatability. CNC machines are also capable of performing multiple operations in a single setup, which reduces the amount of time and labor required to produce a part. Additionally, CNC machines are capable of producing parts with complex geometries that would be difficult or impossible to produce with traditional machining methods. CNC machines are also capable of producing parts with a high degree of precision and repeatability, which is important for producing parts that must meet tight tolerances. Finally, CNC machines are capable of producing parts with a high degree of consistency, which is important for producing parts that must meet exact specifications.

What are the advantages disadvantages and limitations of CNC machining?

CNC machining is a manufacturing process that uses computer numerical control (CNC) machines to shape and cut materials into a desired shape or size. CNC machining is a popular choice for many industries, including automotive, aerospace, medical, and consumer products.

Advantages of CNC Machining

One of the main advantages of CNC machining is its accuracy and repeatability. CNC machines are programmed with precise instructions, and they can produce parts with a high degree of accuracy and repeatability. This means that parts produced with CNC machining are more consistent and reliable than parts produced with traditional machining methods.

CNC machining also offers a high level of flexibility. CNC machines can be programmed to produce a wide variety of parts, from simple to complex. This means that CNC machining can be used to produce parts for a variety of applications, from medical implants to automotive components.

CNC machining is also cost-effective. CNC machines are relatively inexpensive to purchase and maintain, and they can produce parts quickly and efficiently.

What is the biggest disadvantage of using CNC?

The biggest disadvantage of using CNC (Computer Numerical Control) is the cost. CNC machines are expensive to purchase and maintain, and require a significant amount of training to operate. Additionally, CNC machines require a large amount of energy to run, which can be costly. Furthermore, CNC machines are limited in their capabilities, as they are programmed to perform specific tasks and cannot be easily adapted to new tasks. Finally, CNC machines are not as accurate as manual machines, and require frequent calibration and maintenance to ensure accuracy.

What are the difference between manual lathe machine and CNC lathe machine?

The primary difference between a manual lathe machine and a CNC lathe machine is the level of automation. A manual lathe machine requires an operator to manually control the machine’s movements and functions, while a CNC lathe machine is automated and controlled by a computer.

Manual lathe machines are typically used for smaller, simpler parts that require less precision and accuracy. They are also more cost-effective than CNC lathe machines, as they require less maintenance and are easier to operate. Manual lathe machines are also more versatile, as they can be used to create a variety of shapes and sizes.

CNC lathe machines, on the other hand, are used for more complex parts that require higher levels of precision and accuracy. They are more expensive than manual lathe machines, but they are also more efficient and can produce parts faster. CNC lathe machines are also more precise, as they are programmed to follow a specific set of instructions.

Which of the following is not an advantage of CNC?

CNC (Computer Numerical Control) is a type of automation technology that uses computer-controlled machines to perform a variety of tasks. CNC machines are used in a wide range of industries, from automotive to aerospace, and offer a number of advantages over traditional manual machining processes. The main advantages of CNC include increased accuracy, repeatability, and speed, as well as reduced labor costs and improved safety.

One of the main advantages of CNC is its accuracy. CNC machines are able to produce parts with extremely high precision, as they are programmed to follow a set of instructions to the exact specifications. This eliminates the need for manual machining, which can be time-consuming and prone to human error. CNC machines are also able to produce parts with repeatability, meaning that the same part can be produced multiple times with the same exact specifications. This is especially useful for mass production, as it eliminates the need to manually adjust the machine for each part.

What are some disadvantages of using CNC?

CNC (Computer Numerical Control) is a type of automation technology used in the manufacturing industry to control machine tools such as lathes, mills, routers, and grinders. CNC machines are highly accurate and can produce complex parts with a high degree of precision. However, there are some disadvantages to using CNC machines.

One of the main disadvantages of CNC machines is their cost. CNC machines are expensive to purchase and maintain, and require specialized training to operate. Additionally, CNC machines require a significant amount of energy to run, which can increase operational costs.

Another disadvantage of CNC machines is that they are not as flexible as manual machines. CNC machines are programmed to perform specific tasks, and it can be difficult and time-consuming to reprogram them for different tasks. This can limit the range of products that can be produced with CNC machines.

CNC machines also require a significant amount of setup time. This can be a disadvantage if the production run is short or if the product design changes frequently.

What are the advantages of CNC over NC?

CNC (Computer Numerical Control) machines offer a number of advantages over NC (Numerical Control) machines. CNC machines are more precise and accurate than NC machines, as they are programmed using a computer and can be programmed to repeat a specific task with a high degree of accuracy. CNC machines are also more efficient than NC machines, as they can be programmed to perform multiple tasks in a single cycle, reducing the amount of time needed to complete a job. Additionally, CNC machines are more flexible than NC machines, as they can be programmed to perform a variety of tasks, allowing for greater versatility in production.

CNC machines are also easier to use than NC machines, as they are programmed using a computer and can be programmed to repeat a specific task with a high degree of accuracy. This makes them ideal for use in a variety of industries, as they can be programmed to perform a variety of tasks with minimal operator input.