In the world of manufacturing and precision engineering, CNC (Computer Numerical Control) technicians play a crucial role. They are the unsung heroes behind the scenes, ensuring that the machines responsible for crafting intricate components run flawlessly. If you’re considering a career in this field or are simply curious about the CNC technician salary landscape, you’ve come to the right place. In this blog, we’ll delve into the role of a CNC technician and provide an in-depth overview of their salaries.

Understanding the Role of a CNC Technician

Before we delve into the CNC technician salary details, let’s first understand what CNC technicians do. CNC technicians are highly skilled professionals responsible for operating and maintaining CNC machines. These machines are essential in the manufacturing industry because they can create intricate parts and components with unparalleled precision and repeatability.

Key Responsibilities of a CNC Technician:

- Machine Setup: CNC technicians are responsible for setting up CNC machines, including loading the necessary tools and materials, and programming the machine to follow specific instructions.

- Programming: They create, modify, and troubleshoot CNC programs, which are essentially a set of instructions that tell the machine how to move and shape raw materials into finished products.

- Monitoring: CNC technicians closely monitor the machines during operation to ensure they are producing parts according to specifications. They make adjustments as needed to maintain quality and efficiency.

- Maintenance: Regular maintenance and troubleshooting are vital. Technicians perform routine checks, clean the machines, and replace worn-out parts to prevent downtime.

- Quality Control: Ensuring the final products meet quality standards is another crucial aspect of their role. They use various measuring tools to inspect the parts and make necessary adjustments.

CNC Technician Salary Overview

Now that we have a clear picture of the CNC technician’s responsibilities, let’s explore the salary aspects of this profession. CNC technician salaries can vary significantly based on factors such as experience, location, education, and the specific industry they work in. However, we can provide a general overview of what you can expect.

- Entry-Level CNC Technician Salary: For those just starting in the field, an entry-level CNC technician can expect to earn between $30,000 and $40,000 annually. These individuals often have limited experience and may still be learning the intricacies of CNC machinery.

- Mid-Level CNC Technician Salary: As you gain experience and expertise, your salary as a CNC technician will increase. Mid-level technicians with several years of experience can earn an average salary ranging from $45,000 to $60,000 per year.

- Experienced CNC Technician Salary: Highly experienced CNC technicians with a track record of successfully operating and maintaining complex CNC machines can command salaries upwards of $70,000 to $90,000 annually. Some may even reach six-figure incomes.

Factors Influencing CNC Technician Salaries

a. Location: The geographic location of your job can significantly impact your salary. CNC technicians in metropolitan areas or regions with a high cost of living tend to earn higher salaries than those in rural areas.

b. Education: A higher level of education, such as an associate’s degree or certification in CNC machining or a related field, can lead to higher salaries and increased job opportunities.

c. Industry: The industry you work in also plays a role. CNC technicians in industries with high demand for precision machining, such as aerospace or medical device manufacturing, often receive higher compensation.

d. Skills and Specialization: Specialized skills, such as programming complex CNC machines or working with specific materials, can lead to higher pay. Continuous skill development is crucial in this field.

e. Company Size: Larger manufacturing companies may offer higher salaries and more comprehensive benefits packages than smaller operations.

Impact of Experience and Skills

Experience is a cornerstone of the CNC technician profession, and it has a direct impact on salary levels. The more years you spend honing your craft, the more valuable you become to employers. Here’s a closer look at how experience and skills influence CNC technician salaries:

- Experience: CNC technicians with a solid track record of successfully operating and troubleshooting CNC machines are highly sought after. As they accumulate more experience, their salaries tend to rise accordingly. Experienced technicians have a deep understanding of the intricacies of CNC machinery, which can lead to better efficiency and fewer costly errors in production. This level of expertise often translates into higher paychecks.

- Skills: In addition to experience, the specific skills you bring to the table can significantly impact your salary. For example, proficiency in CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software can make you more versatile and valuable in the workplace. Similarly, expertise in programming complex CNC machines, working with advanced materials, or mastering the latest industry technology can command higher compensation.

- Certifications: Earning industry-recognized certifications, such as those from the National Institute for Metalworking Skills (NIMS) or the American Machinists’ Certification Program (AMCP), can boost your earning potential. These certifications validate your skills and can make you a more attractive candidate for high-paying CNC technician positions.

- Problem-Solving Abilities: CNC technicians who excel at troubleshooting and problem-solving are invaluable to employers. Machines can encounter a wide range of issues during operation, and technicians who can quickly diagnose and rectify problems are highly regarded and often rewarded with higher salaries.

Influence of Education on Salary

While experience and skills are crucial factors in determining CNC technician salaries, education also plays a significant role. Here’s how education can influence your earning potential as a CNC technician:

- High School Diploma: Many CNC technicians enter the field with a high school diploma or equivalent. While this is the minimum educational requirement, it often leads to lower starting salaries compared to those with additional education.

- Associate’s Degree: Pursuing an associate’s degree in CNC machining, mechanical engineering technology, or a related field can open doors to higher-paying positions. This level of education provides a more in-depth understanding of CNC technology and machining processes, making you a more attractive candidate to employers.

- Bachelor’s Degree: Although less common, some CNC technicians hold bachelor’s degrees in engineering or a related discipline. These individuals often earn higher salaries and may transition into supervisory or management roles within manufacturing facilities.

- Certifications: As mentioned earlier, industry-recognized certifications can have a substantial impact on salary. Completing relevant certifications demonstrates your commitment to ongoing learning and can lead to better-paying opportunities.

- Continuing Education: The CNC field is constantly evolving with new technologies and processes. Staying current with industry trends through continuing education and training can help you remain competitive in the job market and potentially command a higher salary.

Role of the Employer and Industry

The CNC technician salary landscape can also be significantly influenced by the employer and the specific industry in which you work. Employers vary in terms of their size, resources, and the types of CNC machines they operate. Additionally, different industries have diverse demands for CNC technicians. Here’s how these factors come into play:

- Company Size: Larger manufacturing companies or those that produce high-value components, such as automotive or aerospace manufacturers, often offer more competitive salaries and comprehensive benefits packages. These companies have the resources to invest in skilled CNC technicians who can help optimize production processes and ensure precision.

- Industry: The industry in which you work can have a substantial impact on your salary as a CNC technician. For instance, industries that require extremely high precision and quality, like medical device manufacturing or aerospace, may pay higher wages to attract and retain skilled technicians. On the other hand, industries with lower precision requirements, such as woodworking or plastic molding, may offer slightly lower salaries.

- Company Culture: The culture and values of your employer can also play a role in your compensation. Some companies prioritize employee development and offer competitive wages to retain top talent. Others may have a more conservative approach to salaries, focusing on other benefits or incentives.

- Benefits and Perks: In addition to base salary, employers may offer attractive benefits and perks, such as health insurance, retirement plans, bonuses, and profit-sharing. These can significantly impact your overall compensation package.

Geographical Impact on CNC Technician Salary

Where you work geographically can have a substantial impact on your CNC technician salary. Regional differences in the cost of living, demand for skilled technicians, and the presence of manufacturing industries can all affect your earning potential. Here’s how geographical location influences CNC technician salaries:

- Cost of Living: Areas with a high cost of living, such as major metropolitan regions like New York City or San Francisco, typically offer higher salaries to offset the increased living expenses. CNC technicians in these areas can expect higher wages to maintain a comparable standard of living.

- Demand and Supply: The demand for CNC technicians can vary from one region to another. Areas with a strong manufacturing presence or a high concentration of industrial facilities may have more job opportunities and higher salaries for skilled CNC technicians due to increased demand.

- Rural vs. Urban: Salaries for CNC technicians in rural areas or smaller towns may be lower than those in urban or suburban settings. However, lower living costs in rural areas can offset the lower salaries, making them more appealing to some individuals.

- State and Local Regulations: State and local regulations can also impact wages. Some regions may have laws or industry-specific agreements that dictate minimum pay rates or provide additional benefits to CNC technicians.

- Relocation Opportunities: For CNC technicians who are open to relocation, moving to regions with a higher demand for their skills can lead to increased earning potential. Employers in such areas may offer relocation packages and competitive salaries to attract talent.

Average Salary By State

To provide a clearer picture of how geographical location impacts CNC technician salaries, let’s delve into some specific examples of average salaries by state in the United States. Keep in mind that these figures can change over time due to factors such as economic conditions and industry demand. As of my last knowledge update in September 2021, here are some approximate average CNC technician salaries by state:

- California: California often boasts some of the highest CNC technician salaries in the nation, primarily due to the high cost of living in the state. On average, CNC technicians in California can earn between $55,000 and $80,000 annually.

- Texas: Texas, with its thriving manufacturing industry, offers competitive salaries to CNC technicians. The average salary in the state ranges from $45,000 to $65,000 per year.

- Michigan: Known for its strong automotive manufacturing sector, Michigan is a hub for CNC technicians. Technicians in the state can expect average salaries in the range of $50,000 to $70,000 annually.

- North Carolina: With a growing manufacturing industry, North Carolina offers CNC technicians competitive wages, typically ranging from $45,000 to $65,000 per year.

- Ohio: Ohio is another state with a significant manufacturing presence, particularly in industries like aerospace and automotive. CNC technician salaries in Ohio usually fall between $45,000 and $65,000 annually.

- New York: In states like New York, where the cost of living is relatively high, CNC technicians tend to earn higher salaries. The average annual salary can range from $55,000 to $80,000.

- Florida: Florida offers competitive salaries for CNC technicians, with average annual earnings ranging from $45,000 to $65,000.

- Illinois: Home to a diverse range of manufacturing industries, Illinois provides CNC technicians with salaries that typically range from $50,000 to $70,000 annually.

Please note that these figures are approximate and can vary depending on factors like experience, education, and location within the state.

Tools and Equipment Used by CNC Technicians

CNC technicians work with a wide array of tools and equipment to perform their duties effectively. These tools are essential for setting up, operating, and maintaining CNC machines. Here are some of the common tools and equipment used by CNC technicians:

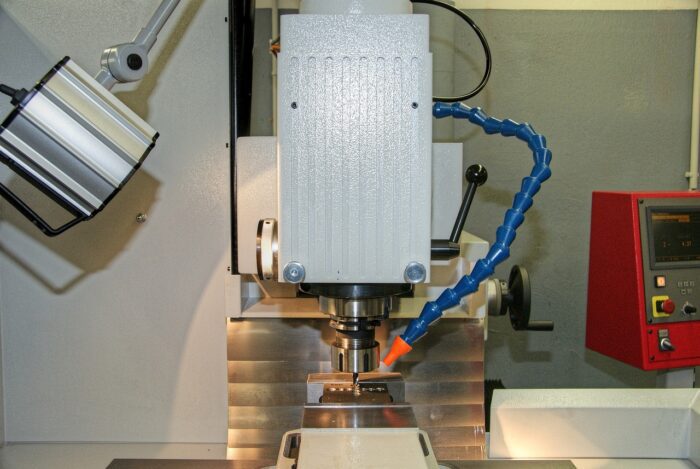

- CNC Machines: CNC technicians operate various types of CNC machines, including milling machines, lathes, routers, and laser cutters. These machines are the heart of precision manufacturing and are used to shape and form raw materials into finished products.

- Computer-Aided Design (CAD) Software: CNC technicians often use CAD software to create detailed blueprints and design files for the components they will manufacture. These files serve as the basis for CNC machine programming.

- Computer-Aided Manufacturing (CAM) Software: CAM software is used to convert CAD design files into CNC machine code, which contains instructions on how the machine should move and cut materials.

- Measuring and Inspection Tools: CNC technicians rely on a range of measuring instruments, such as calipers, micrometers, and gauges, to ensure that finished parts meet precise specifications and quality standards.

- Cutting Tools: Cutting tools like end mills, drills, and turning tools are used to shape and cut materials during the machining process. CNC technicians are responsible for selecting the appropriate tools and ensuring they are in good condition.

- Tool Holders and Fixtures: Tool holders securely hold cutting tools in place during machining, while fixtures are used to hold workpieces in position. Proper setup of tool holders and fixtures is critical for accurate machining.

- Safety Equipment: Safety is paramount in CNC machining. Technicians use personal protective equipment (PPE) such as safety glasses, ear protection, and gloves to safeguard themselves while working with machines.

- Maintenance Tools: CNC technicians perform routine maintenance on machines, including cleaning, lubricating, and replacing worn or damaged parts. Tools such as wrenches, screwdrivers, and lubrication equipment are essential for these tasks.

- Diagnostic Equipment: When troubleshooting machine issues, technicians may use diagnostic tools like multimeters and oscilloscopes to identify electrical or mechanical problems.

- Programmable Logic Controllers (PLCs): PLCs are used to control the operation of CNC machines. Technicians may need to program or troubleshoot PLCs to ensure machines function correctly.

Career Growth and Economic Advancement

For CNC technicians, career growth and economic advancement opportunities are not just possible; they are an integral part of the profession. As you accumulate experience, expand your skill set, and pursue ongoing education, you can unlock several avenues for advancement:

- Senior CNC Technician: With years of experience, you can transition into senior or lead CNC technician roles. These positions often involve supervising a team of technicians, overseeing production processes, and ensuring quality control. Senior CNC technicians typically earn higher salaries than their junior counterparts.

- CNC Programmer: If you excel in CNC programming and have a deep understanding of CAD/CAM software, you can become a CNC programmer. This role involves creating and optimizing CNC programs for machines. CNC programmers are in high demand and often command higher salaries due to their specialized skill set.

- Quality Control Inspector: Some CNC technicians transition into quality control roles, where they inspect finished products to ensure they meet strict quality standards. Quality control inspectors play a critical role in maintaining product integrity, and their expertise can lead to salary increases.

- Manufacturing Supervisor/Manager: Career progression may also take you into supervisory or management roles within manufacturing facilities. As a supervisor or manager, you’ll oversee teams of CNC technicians and other production staff, with the potential for substantial salary increases.

- Consultant or Trainer: Experienced CNC technicians often become consultants or trainers, sharing their knowledge and expertise with others in the field. These roles may involve working for educational institutions, manufacturing companies, or as independent consultants, and they can be financially rewarding.

Comparing CNC Technician with CNC Machinist

While the terms “CNC technician” and “CNC machinist” are sometimes used interchangeably, they represent distinct roles within the CNC machining industry. Let’s compare the two to clarify their differences:

CNC Technician:

- Primary Responsibilities: CNC technicians focus on the operation and maintenance of CNC machines. They ensure that machines are set up correctly, programmed accurately, and maintained to produce parts with precision.

- Skills: CNC technicians need a broad skill set that includes machine operation, programming, troubleshooting, maintenance, and quality control.

- Education: Entry-level positions often require a high school diploma or equivalent, but higher education and certifications can lead to better opportunities and salaries.

- Salaries: CNC technician salaries, as discussed earlier, vary based on factors like experience, skills, and location. They typically range from $30,000 to $90,000 or more annually.

CNC Machinist:

- Primary Responsibilities: CNC machinists are primarily responsible for setting up and operating CNC machines. They follow instructions provided by CNC technicians or programmers to produce parts.

- Skills: CNC machinists need strong technical skills, particularly in machine setup, operation, and tool changes. They rely on CNC programs created by technicians or programmers.

- Education: Entry-level positions often require a high school diploma or equivalent, with additional training provided on the job or through technical programs.

- Salaries: CNC machinist salaries are also influenced by factors like experience and location. They typically range from $30,000 to $60,000 annually.