Computer Numerical Control machining has revolutionized the manufacturing industry by enabling highly accurate and efficient production of complex parts. Over the years, advancements in technology have played a significant role in enhancing CNC machining capabilities. One of the most transformative technologies in recent times is Artificial Intelligence (AI). AI, coupled with CNC machining, has led to a new era of precision and efficiency, transforming the way we design, prototype, and manufacture products. In this blog, we will delve into the impact of AI in CNC machining, exploring the benefits, applications, and future possibilities.

Understanding CNC Machining

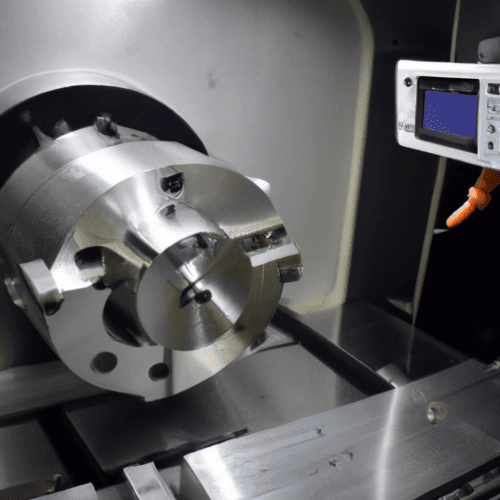

CNC machining is a manufacturing process where computer-controlled machines precisely cut, shape, and finish raw materials to create intricate parts and components. Traditional CNC machines operate using pre-programmed instructions, following a set of commands to produce the desired output. However, the integration of AI technology has opened up new avenues for optimizing CNC machining processes.

The Role of AI in CNC Machining

AI algorithms and machine learning techniques have been integrated into CNC machining systems to enhance precision, efficiency, and productivity. Here are some key areas where AI is making a significant impact:

a. Design Optimization: AI can analyze complex design requirements and generate optimized tool paths that minimize material waste, reduce production time, and improve the overall quality of the finished parts. By considering multiple variables simultaneously, AI algorithms can identify the most efficient machining strategies that human programmers may overlook.

b. Adaptive Machining: AI can monitor and analyze real-time sensor data from CNC machines, adjusting machining parameters dynamically to optimize performance. By continuously learning from sensor inputs, AI algorithms can adapt to changing conditions, minimizing errors, and improving the accuracy of machining processes.

c. Predictive Maintenance: AI-powered CNC machines can analyze historical data, sensor readings, and machine performance metrics to predict maintenance requirements. By detecting anomalies and patterns, AI algorithms can identify potential failures before they occur, enabling proactive maintenance and minimizing downtime.

d. Quality Control: AI can automate the inspection and quality control process in CNC machining. Vision systems equipped with AI algorithms can quickly and accurately detect defects, measure dimensions, and compare finished parts against design specifications. This automated inspection reduces human error and ensures high-quality output.

Benefits of AI in CNC Machining

The integration of AI in CNC machining offers several compelling benefits:

a. Enhanced Precision: AI algorithms enable fine-tuning of machining parameters, resulting in higher precision and accuracy. By eliminating human errors and optimizing tool paths, AI ensures consistent part quality and dimensional accuracy.

b. Increased Efficiency: AI-powered CNC machines can operate at optimal speeds, reducing cycle times and improving overall production efficiency. Real-time monitoring and adaptive control help minimize downtime, optimize tool changes, and improve material utilization.

c. Cost Reduction: AI-driven optimization in CNC machining leads to reduced material waste, energy consumption, and manual labor costs. By streamlining the manufacturing process, AI enables manufacturers to achieve cost savings and improve profitability.

d. Improved Safety: AI-powered CNC machines can detect potential safety hazards and take corrective actions, reducing the risk of accidents. Real-time monitoring of machine health and predictive maintenance enable proactive measures to ensure a safe working environment.

Applications of AI in CNC Machining

AI’s impact on CNC machining is visible across various industries:

a. Aerospace and Automotive: In these sectors, where precision and complex geometries are crucial, AI enhances the manufacturing of critical components, such as turbine blades, engine blocks, and aerospace structures.

b. Medical and Healthcare: AI-assisted CNC machining is used in the production of medical devices, implants, prosthetics, and other precision instruments. The integration of AI ensures strict adherence to design specifications, critical for patient safety.

c. Electronics: AI-driven CNC machining enables the production of intricate electronic components, circuit boards, and microelectromechanical systems (MEMS). The high precision and efficiency provided by AI improve the performance and reliability of electronic devices.

d. Mold and Die Making: AI algorithms optimize the tool paths and machining parameters for mold and die manufacturing. This results in faster turnaround times, improved surface finishes, and increased tool life.

Future Possibilities

The future of AI in CNC machining holds tremendous potential. Here are a few exciting possibilities:

a. Autonomous CNC Systems: AI-powered CNC machines may become fully autonomous, capable of self-optimization, self-programming, and self-monitoring. This would reduce the dependence on human intervention and further enhance precision and efficiency.

b. Generative Design: AI algorithms can generate innovative designs by exploring a vast range of possibilities. These designs can then be seamlessly translated into optimized tool paths, enabling the production of highly complex and efficient parts.

c. Collaborative Robotics: AI-powered CNC machines can collaborate with robotic systems, enabling seamless integration of machining and automation. This would enhance productivity, flexibility, and safety in manufacturing processes.

d. Virtual Reality (VR) and Augmented Reality (AR): AI, combined with VR and AR technologies, can provide real-time visualization, simulation, and virtual prototyping capabilities. This would revolutionize the way designers and engineers interact with CNC machines, leading to faster iterations and improved design outcomes.

The Impact of AI in CNC Machining: Frequently asked questions

AI has revolutionized CNC machining productivity by optimizing various aspects of the process. Through advanced algorithms and machine learning, AI can analyze large amounts of data to identify patterns and make predictions. This enables AI-powered CNC machines to optimize cutting paths, tool selection, and machining parameters, resulting in faster production times and increased efficiency.

Can AI improve CNC machining precision and accuracy?

Absolutely! AI brings enhanced precision and accuracy to CNC machining. By continuously analyzing real-time sensor data and adjusting machining parameters, AI can make precise adjustments to maintain optimal cutting conditions. This results in improved part quality, reduced errors, and tighter tolerances, ultimately leading to higher overall accuracy in CNC machining operations.

How does AI enhance CNC machining quality control?

AI plays a crucial role in quality control in CNC machining. It can analyze sensor data in real-time to detect anomalies or deviations from the expected results. By monitoring variables such as temperature, vibration, and tool wear, AI systems can identify potential issues before they cause defects or failures. This proactive approach allows for early intervention, reducing scrap rates and ensuring consistent quality throughout the manufacturing process.

Can AI optimize CNC machining tool life?

Yes, AI is instrumental in maximizing tool life in CNC machining. By continuously monitoring and analyzing tool usage data, AI algorithms can predict the remaining useful life of cutting tools. This information enables operators to schedule tool changes proactively, minimizing unplanned downtime and reducing costs associated with premature tool failure. Additionally, AI can optimize tool paths and cutting strategies to distribute the workload evenly across multiple tools, further extending their lifespan.

What are the potential benefits of AI in CNC machining?

AI offers several key benefits in CNC machining, including increased productivity, improved precision and accuracy, enhanced quality control, optimized tool life, and reduced costs. By leveraging AI capabilities, manufacturers can streamline their operations, minimize waste, and deliver high-quality parts with faster turnaround times. AI also empowers CNC machines to adapt and learn from real-time data, paving the way for autonomous machining and continuous process improvement.

The integration of AI in CNC machining has brought forth a new era of precision, efficiency, and automation. AI algorithms and machine learning techniques optimize tool paths, adapt to changing conditions, predict maintenance requirements, and improve quality control. The benefits of AI in CNC machining extend beyond increased precision and efficiency; they encompass cost reduction, improved safety, and enhanced competitiveness. As AI continues to advance, the possibilities for further innovation and optimization in CNC machining are truly exciting. With AI as a driving force, we can expect continued growth and advancements in the manufacturing industry, shaping a future of smarter and more efficient production processes.