The aerospace industry has always been at the forefront of technological advancements, constantly pushing the boundaries of innovation. One of the key technologies driving this progress is Computer Numerical Control (CNC) machines. These sophisticated machines have revolutionized precision manufacturing in the aerospace industry, enabling the production of intricate and complex components with unmatched accuracy and efficiency. In this blog, we will explore how CNC machines are transforming the aerospace industry, their benefits, and the implications for the future of aerospace manufacturing.

Precision Manufacturing at Unmatched Levels

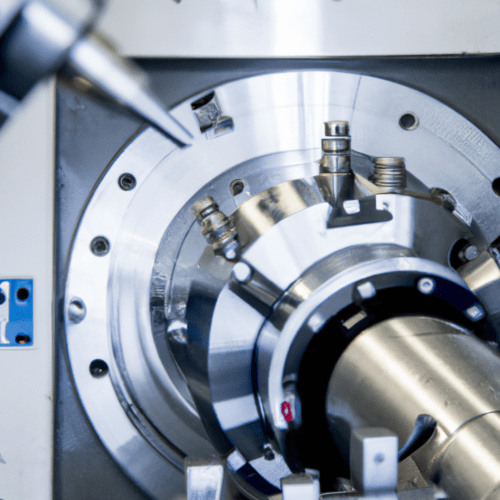

Precision is of utmost importance in the aerospace industry, where even the smallest deviation can have severe consequences. CNC machines excel in producing highly accurate components repeatedly, ensuring consistency and reliability. These machines can achieve tolerances as low as a few microns, guaranteeing a perfect fit and minimizing any potential for human error. This level of precision is crucial in manufacturing critical aerospace parts such as turbine blades, engine components, structural elements, and intricate assemblies.

Complex Geometry Made Feasible

Aerospace designs often involve complex geometries that would be nearly impossible to manufacture without CNC machines. These machines can handle intricate shapes, contours, and undercuts with ease, allowing aerospace engineers to push the boundaries of design innovation. Whether it’s creating lightweight structures, optimizing aerodynamics, or integrating complex features, CNC machines enable the production of components that were once considered unattainable.

Increased Efficiency and Cost Reduction

CNC machines offer unparalleled efficiency compared to traditional manufacturing methods. Once the machine is programmed, it can work continuously, 24/7, with minimal human intervention. This leads to reduced production time, increased productivity, and significant cost savings. Additionally, CNC machines optimize material usage, minimizing waste and maximizing yield, further contributing to cost reduction. The combination of precision, efficiency, and cost-effectiveness makes CNC machines an indispensable asset in aerospace manufacturing.

Improved Safety and Quality Assurance

The aerospace industry demands the highest standards of safety and quality assurance. CNC machines play a crucial role in ensuring compliance with these standards. By automating the manufacturing process, CNC machines eliminate the risks associated with manual operations, reducing the potential for human error and increasing workplace safety. Furthermore, CNC machines are equipped with advanced sensors and monitoring systems that detect any deviations or anomalies during production, ensuring consistent quality and enabling prompt corrective actions.

Accelerating Innovation and Rapid Prototyping

Innovation is the lifeblood of the aerospace industry, and CNC machines empower engineers to explore new ideas and concepts quickly. With their ability to produce prototypes rapidly and accurately, CNC machines accelerate the design iteration process. Engineers can test and refine their designs, evaluate performance, and make necessary adjustments in a fraction of the time it would take with conventional manufacturing methods. This accelerated innovation cycle allows aerospace companies to bring new products and technologies to market faster, gaining a competitive edge in the industry.

Future Implications and Advancements

As technology continues to evolve, CNC machines are poised to play an even more significant role in the aerospace industry. Advancements in machine learning, artificial intelligence, and robotics are being integrated into CNC systems, enabling autonomous decision-making, adaptive machining, and enhanced process optimization. These developments will further improve precision, efficiency, and productivity, opening up new possibilities for aerospace manufacturing.

CNC Machines in Aerospace Industry: Frequently asked questions

CNC machines are extensively utilized in the aerospace industry for various applications, including:

a. Machining structural components: CNC machines are employed to fabricate structural components such as wing spars, fuselage frames, landing gear components, and engine parts. These machines precisely cut, shape, and drill the aerospace-grade materials required for these components.

b. Manufacturing complex parts: The aerospace industry often requires intricate and complex parts. CNC machines are capable of performing multi-axis milling, turning, and drilling operations to create these components with high precision and repeatability.

c. Prototyping and tooling: CNC machines are instrumental in creating prototypes of new aircraft designs. They can rapidly produce accurate models that help engineers evaluate the form, fit, and function of various parts before mass production. CNC machines are also used to manufacture molds, jigs, and fixtures required in the aerospace manufacturing process.

d. Repair and maintenance: CNC machines are utilized for the repair and maintenance of aircraft components. These machines can restore damaged parts to their original specifications, ensuring their reliability and safety.

What are the advantages of using CNC machines in the aerospace industry?

The use of CNC machines in the aerospace industry offers numerous benefits, including:

a. Precision: CNC machines provide exceptional accuracy and repeatability, enabling the production of components with tight tolerances. This precision is crucial for ensuring the structural integrity and performance of aircraft.

b. Efficiency: CNC machines automate manufacturing processes, reducing human error and increasing production efficiency. They can work continuously, 24/7, improving productivity and reducing lead times.

c. Flexibility: CNC machines can be programmed to produce a wide range of complex components, making them highly versatile. They can quickly switch between different tasks, minimizing downtime and setup costs.

d. Quality control: CNC machines offer superior quality control through their ability to perform in-process measurements and inspections. This ensures that components meet the required specifications and standards.

e. Safety: CNC machines enhance workplace safety by reducing the need for manual handling of heavy materials and minimizing the risk of accidents associated with manual machining operations.

What materials can be machined using CNC machines in aerospace applications?

CNC machines can handle a wide range of aerospace-grade materials, including:

a. Aluminum: Aluminum alloys are commonly used in aerospace manufacturing due to their lightweight, corrosion resistance, and high strength-to-weight ratio. CNC machines efficiently cut and shape aluminum components.

b. Titanium: Titanium and its alloys possess excellent strength, heat resistance, and corrosion resistance. CNC machines can handle titanium, enabling the fabrication of critical aerospace components like engine parts and landing gear.

c. Composites: Carbon fiber-reinforced polymers (CFRP) and other composite materials are increasingly utilized in aerospace applications due to their high strength and lightweight properties. CNC machines equipped with specialized tools can effectively machine composites, maintaining precision and surface finish.

d. Stainless steel: Stainless steel is employed in aerospace applications where corrosion resistance and strength are vital. CNC machines can perform milling, turning, and drilling operations on stainless steel components.

Are CNC machines replacing traditional machining methods in aerospace manufacturing?

While CNC machines have significantly transformed aerospace manufacturing, traditional machining methods still have their place in certain applications. CNC machines offer advantages in terms of speed, precision, and automation, but traditional machining methods may be preferred for specialized operations or low-volume production. Both approaches coexist, with CNC machines augmenting and enhancing traditional machining processes in the aerospace industry.

CNC machines have transformed the aerospace industry by revolutionizing precision manufacturing. With their ability to produce complex components with unmatched accuracy, CNC machines have become indispensable tools in aerospace manufacturing processes. The benefits they bring, including increased efficiency, reduced costs, improved safety, and accelerated innovation, make them a cornerstone of the industry’s progress. As technology advances, CNC machines will continue to push the boundaries of precision manufacturing, enabling new frontiers in aerospace engineering and propelling the industry into the future.